The True Cost of Inefficiency

Despite the widespread adoption of digitalization and the use of AI-based tools, some manufacturers still believe that they can do without, yet the real cost of not automating manufacturing is often too high. Non-automated manufacturing companies face a number of problems related to inefficiency, lower product quality, and costs.

First of all, in such a production facility, manufacturing processes depend on the skills and experience of employees, and also on their moods. This often leads to instability and low productivity. In addition, non-automated processes require a large number of employees to perform, which means increased labor costs. The execution of processes by humans is often the cause of production errors and defective goods. Other common mistakes caused by human factors include inaccurate measurements, incorrect assembly, or insufficient quality control.

Non-automated companies often find it difficult to implement new technologies and are unable to effectively plan production processes or track the progress of orders. However, the real hidden costs of manual manufacturing processes are the inability to grow and the real difficulties found in quality control. Such companies are often unable to scale, because increasing production volumes entails a significant expansion of staff, which is expensive and difficult.

Unfortunately, very often, manufacturing inefficiencies and losses lead to the closure of a company. Therefore, in this article, we will talk about the three main pain points of non-automated manufacturing and share information on how Odoo solutions help to get rid of these problems and significantly improve the efficiency of all processes.

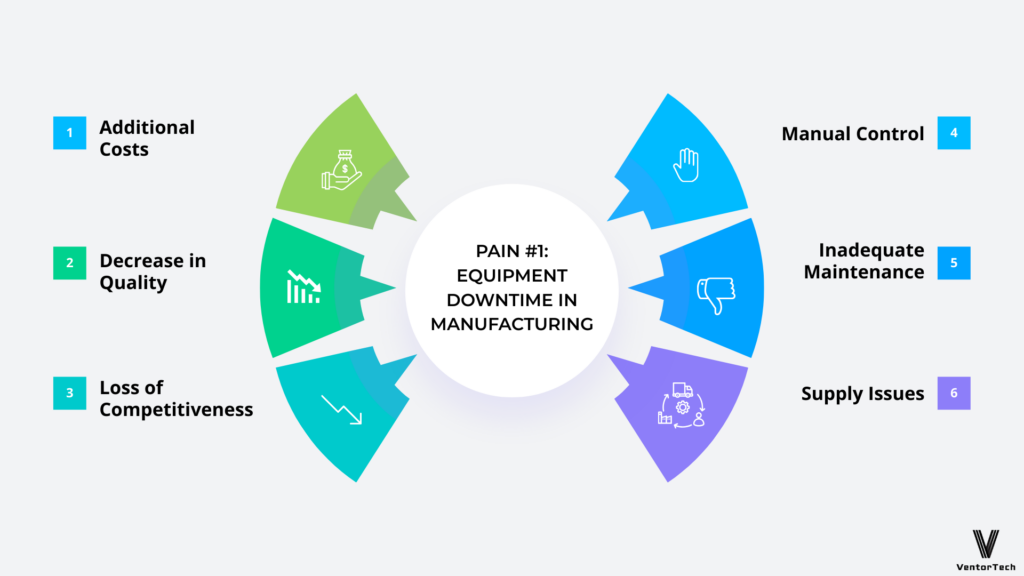

Pain #1: Equipment Downtime in Manufacturing

Equipment plays a key role in manufacturing since it minimizes the cost of producing one unit of a product. High-quality equipment ensures efficient, fast, and consistent production of premium-quality products. Equipment downtime in manufacturing, the time when machines are not running due to scheduled maintenance or unforeseen breakdowns, leads to large financial losses and reduced customer satisfaction.

Equipment downtime results in production stoppages and reduced efficiency. Workers and production managers usually perceive downtime as an inevitability, and without production automation, they are correct. Equipment downtime is a much more serious and deeper problem than it may seem at first, and below, we will elaborate on the impact of downtime on production efficiency.

Additional Costs

When employees are not working due to equipment downtime, enterprises must still pay their wages. Manufacturers continue to incur heating and lightning expenses, even when their equipment is not working. What is more, after a break, additional costs are incurred to restart production, such as warming up or cooling down.

Decrease in Quality

Equipment adjustment is the reason for the increase in the number of rejects. In addition, due to downtime, there is a shortage of time, and production processes are accelerated to fulfill the plan. As a result, the quality of the products decreases significantly.

Loss of Competitiveness

Downtime worsens all performance indicators of the enterprise, reducing productivity and overall efficiency. An increase in expenses leads to an increase in production costs, and together with deterioration of quality and violation of deadlines, customer satisfaction levels and enterprise competitiveness decline significantly.

Lack of automation in manufacturing has a direct impact on downtime, as non-automated processes and manual labor are more prone to errors and require longer times for changeovers. A few examples below show the involvement of the lack of automation in equipment downtime.

Manual Control

If the manufacturing operations do not utilize an automated process control system, employees must manually monitor and adjust the equipment. This greatly increases delays and inaccuracies, and setup errors can lead to equipment breakdowns and additional costs.

Inadequate Maintenance

Without automated systems for preventive maintenance planning, equipment failures go unnoticed for long periods of time. This leads to the accumulation of problems and long-term breakdowns.

Supply Issues

It is important that materials and components are ordered and received as soon as possible. However, non-automated processes lead to delays in deliveries and, as a consequence, to downtime for equipment while waiting for the required parts.

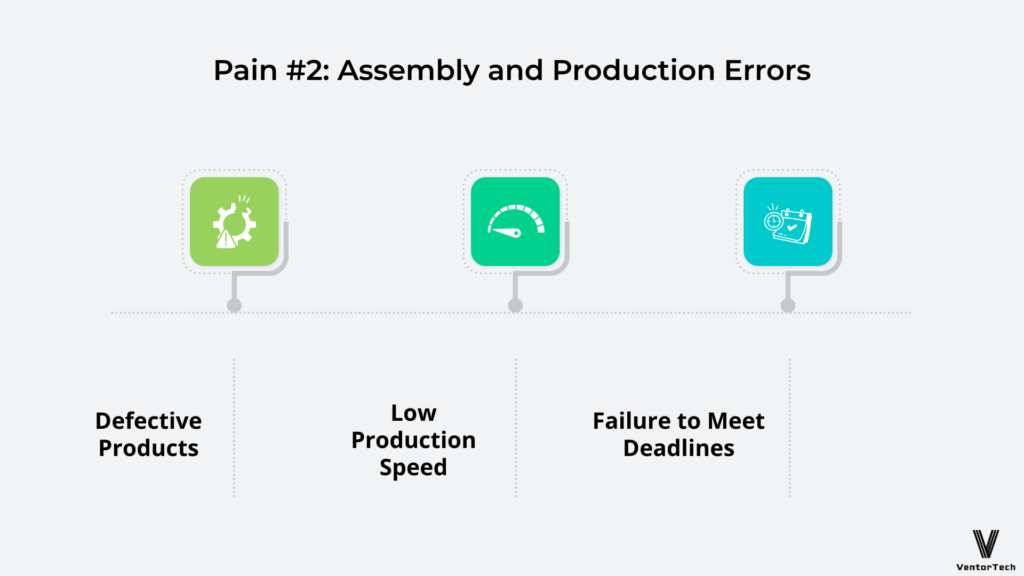

Pain #2: Assembly and Production Errors

Assembly and manufacturing processes are extremely important for any industry, as their efficiency strongly affects the quality of the final product and its cost. Failing to automate these processes negatively affects the company’s overall productivity. This is especially true in the furniture industry, where the accuracy of production processes plays a key role in the success of the company.

As in other processes, errors in non-automated assembly and manufacturing are often due to human factors. Below, we provide examples of the main errors in the assembly and production of goods without process automation.

Defective Products

In non-automated furniture factories, most of the processes are done manually. Skipping assembly steps or incorrect installation often results in defective products. Operations are carried out with less precision, thus reducing product quality while increasing the number of rejects. This leads to a poor reputation and negative customer experiences. Defective pieces of furniture do not fully fulfill their function and are therefore more likely to be returned to the company, which increases costs and reduces profit margins.

Low Production Speed

Manual assembly significantly reduces productivity as it is more time consuming. Employees get tired, sick, and have bad moods, which are all factors that reduce productivity. Without automated systems, production cannot run 24/7 without interruptions, which negatively affects efficiency.

Failure to Meet Deadlines

Non-automated processes have rather low speed and efficiency. This slows down getting products to the market and increases production time. In a modern, highly competitive environment, this can be a decisive factor for an enterprise. Assembly and production errors in manufacturing, including furniture manufacturing, lead to a decrease in a company’s reputation in the market and a loss of customers.

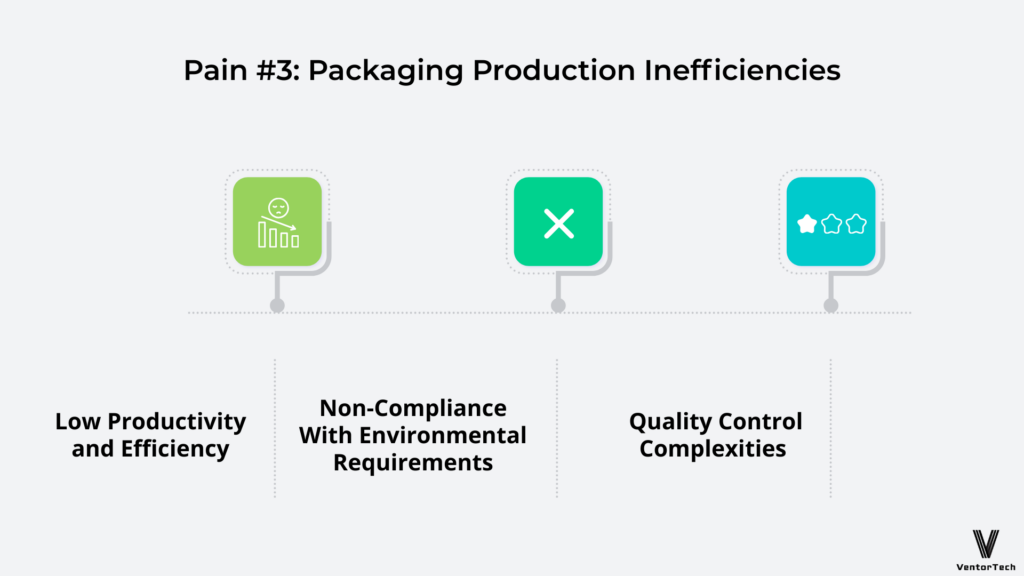

Pain #3: Packaging Production Inefficiencies

Product packaging is an important identifier of the manufacturer, since it allows for distinguishing the brand from its competitors. The production packaging process has a direct impact on the safety of the product throughout the entire logistics chain. Packaging process optimization in factories is impossible without automation, and below, we will discuss why automation is so important.

Low Productivity and Efficiency

Non-automated packaging involves the use of manual labor. This increases the time it takes to pack a unit of a product and reduces the total quantity produced. Manual labor also leads to more inaccuracies and errors in the packaging process, resulting in more returns. Some of the most popular errors include mislabeling, incorrect product placement, and damaged packaging.

Non-Compliance With Environmental Requirements

Sustainable packaging is extremely important to consumers today, but it is virtually impossible without automation. Non-automated processes involve the use of huge quantities of packaging materials. Some of these materials may not be recyclable, which increases the environmental burden and reduces customer satisfaction.

Quality Control Complexities

The main quality control problems of the non-automated packaging process are also related to human factors. The quality of product packaging is directly dependent on the attention, skills, and experience of the employee involved. In addition, such a recovery quality assessment often leads to discrepancies. Uniformity of packaging processes is also difficult to ensure in the absence of automation. Thus, a lack of automated quality controls result in packaging production inefficiencies and varying degrees of product quality.

How Odoo Helps Solve These Problems

The problems we have described above cause marked damage to production and hinder its development. Production processes automation significantly improves efficiency, control, internal communications, customer relations, and many other aspects. Modern manufacturers prefer solving manufacturing bottlenecks with ERP, a sophisticated software system employed to manage all enterprise processes.

The Odoo system is an excellent solution for companies that want to automate their production processes and more. Odoo provides real examples of automation ROI in manufacturing, which proves its efficiency in this sphere. Odoo is a package of open-source applications integrated with each other that are able to cover the needs of automating working processes at enterprises of any scale and direction.

The advantage of the Odoo system is its modular structure that allows enterprises to implement only the necessary modules and add new ones as the need for them grows. Some of the most popular Odoo modules are CRM, Warehouse Management, Digital Marketing, E-commerce, and many others.

Advantages of Odoo ERP for Manufacturers

Equipment Management

Odoo can safely be called one of the best software solutions for servicing modern manufacturers that ensures manufacturing error prevention through automation, since the variety of its modules allows them to effectively manage all business processes. Odoo is an excellent assistant for eliminating the main causes of costly defects and ensuring a high level of quality throughout the entire product lifecycle.

Odoo offers excellent tools for equipment failure prevention in manufacturing. This system helps to automate preventive maintenance, so production does not come to a halt. The Odoo instruments calculate standard indicators for preventive maintenance planning and allow manufacturers to automate metrological processes and preventive maintenance scheduling.

The Odoo system allows for efficient management of maintenance requests. Manufacturers can easily track the progress of maintenance requests in Kanban mode. In addition, Odoo allows you to use a maintenance calendar to organize and schedule work.

Production Management

Odoo manufacturing automation solutions create stable conditions for production growth through effective production processes management. The system allows you to plan production schedules based on equipment capacity and material availability. Thus, companies avoid overproduction and optimize resource utilization.

Odoo also provides tools to monitor production operations in real time. This provides the ability to track order fulfillment and monitor product quality. Odoo automates a huge number of tasks in production, such as moving materials or generating purchase orders. This saves employees time and resources and reduces the likelihood of errors.

Odoo ERP significantly increases employee efficiency through an intuitive interface. It allows them to quickly find necessary information, which simplifies workflow processes. Odoo also ensures quality control improvement with automation, and this improves customer experience.

Warehouse Management With Odoo

The Odoo system allows you to create and manage specific storage locations, including aisles and shelves, and brings numerous automation benefits for packaging lines. This makes goods more accessible and thus simplifies the packaging process.

Odoo provides specialized dashboards to help order fulfillment, quality control, packaging, and receiving teams keep track of daily operations. It is important to note that the priority is given to tasks with immediate deadlines to ensure that orders are completed on time. Odoo tools greatly improve the process of packaging goods. The application allows you to assign barcodes to sealed boxes, so you can track the contents in real time. If the location information of the boxes is updated, the location of the contents is automatically updated.

Odoo also offers production waste reduction strategies and provides detailed write-off reports with costs, reasons, and quantities.

Future-Proof Your Manufacturing with Odoo — Start Your Automation Journey Today.

Final Thoughts

Manufacturing automation is a prerequisite for the successful operation of any modern enterprise. Automated systems work much faster and more accurately, and thus reducing order fulfillment time while increasing the number of products manufactured. In addition, automation allows you to reduce material costs and labor resources while also reducing the amount of waste.

Odoo ERP is an excellent tool for automating and optimizing company processes. It boasts of countless industrial automation cost savings examples among the cases of its users. Odoo implementation leads to increased efficiency and a better reputation for companies utilizing this solution.

To wrap up, here is how Odoo ERP helps manufacturers:

- Increases efficiency by automating routine processes

- Improves safety by assembly line optimization with technology

- Expands opportunities for customizing the system to meet the needs of the business

- Creates a single information space that provides transparency and simplifies the control of processes

You can see for yourself how automation reduces manufacturing costs and makes production more efficient. Digital technologies have already touched many areas of activity, and soon, manufacturers that have not automated their processes will not be able to be competitive and keep up with continually changing customer expectations.

Recommended articles:

- How a US Repair Company Scaled Up After Migrating from a Legacy System to Odoo

- U.S. automotive company: 15X Growth with Odoo

- Half a million Euros’ profit from Odoo ERP integration – a high-end cigar business success story

- How an Odoo Inventory optimization generated $200K for a US company

- Multicare-centrum.nl success story – How to make a 2.8M EUR turnover with 3.5 employees

----------------------------------------------------------------------

Education: Bachelor's degree.

----------------------------------------------------------------------

Experience:

Marketing manager

VentorTech

----------------------------------------------------------------------

Current position: Marketing manager VentorTech

----------------------------------------------------------------------

B2B Marketing

Google Tag Manager and GA

0 Comments