This article covers all steps for warehouse management system (WMS) implementation for SME. If you are not sure that you need a WMS or Inventory Management System we recommend you review the first article Is it the right time to integrate WMS into the company? Based on the special checklist, you can easily understand if you need such a complex system as WMS.

Table of contents

1. Intro

2. Gathering of requirements

2.1 How to generate a list of requirements for SME

3. Choosing WMS and vendor

3.1 Overview of warehouse processes

3.2 Types of WMS providers

3.2.1 Supply Chain Systems

3.2.2 Ecommerce + WMS

3.2.3 WMS + Barcode Scanners

3.2.4 WMS as a part of ERP system

3.2.5 Industry solution

3.2.6 Mixed solutions

3.2.7 Area of customization

3.3 Desktop, Cloud, On-premise and Hybrid solutions

3.4 The recommended steps to choose WMS provider

4. Discuss implementation approach

5. WMS deployment and customization

5.1 Requirements Gathering And Analysis

5.1.1 Requirements Gathering

5.1.2 Requirements Analysis

5.2 Warehouse process optimizations

5.3 System Design

5.3.1 System Architecture Design

5.3.2 Gap Analysis

5.3.3 Scope of Work (SOW) Creation

5.3.4 Functional Specifications

5.4 System Implementation

5.4.1 Install WMS system

5.4.2 Design virtual WH

5.4.3 Mandatory customizations

5.4.4 Import customer data

5.4.5 Make initial inventory

5.4.6 Sales and procurements rules

5.4.7 3rd party software integration

5.4.8 3rd party hardware integration

5.4.9 Additional customizations

5.5 Integration and Functional Testing

5.6 Acceptance and Training

5.6.1 Acceptance Testing

5.6.2 Training

5.7 Change Management

5.8 Go live

6. Post Go-Live support

7. Costs and lead time

8. Summary

Our thanks

Welcome to colaborate

1. Intro

Before looking into WMS as a solution, you should know what you really need and why you need it. Mainly, in this article we will focus on the customer’s needs and necessary steps. You will find a vendor’s point of view as well as the most important milestones to see the life cycle of a successful project.

Note that implementation guide is quite standard and in 80% of cases it can be applied to the process of implementation of other business solutions. So let’s start step by step to see the whole process.

2. Gathering of requirements

In the most cases, at this stage, the customer already has a list of business requirements (wishes). But mostly, the list doesn’t cover all cases because of lack of internal analysis and miscommunication between departments. Most of the time, the customer doesn’t even provide the main reason why they need the system.

“If you don’t know where you’re going, any road will take you there” – Lewis Carroll

Why do you need to make a list of requirements before going to a vendor? First, you will see the main internal problems and discuss them with your team. Second, if you prepare a list of requirements by yourself, it will help solve inconsistencies in the vision for different departments, which in turn will save time on approvals for future steps.

Remember, the goal of the vendor is to provide the solution and cover all business needs of the customer. To prepare a correct list of requirements you can use the step by step approach below.

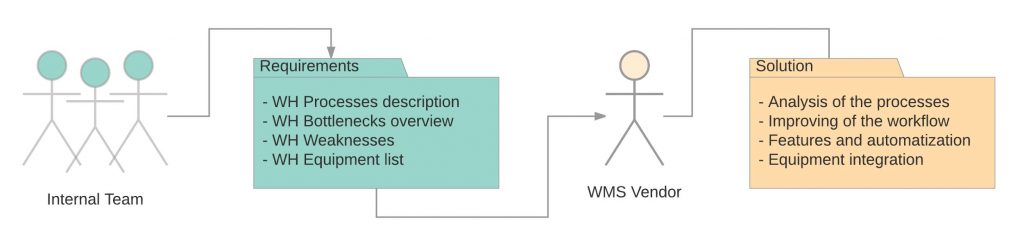

2.1 How to generate a list of requirements for SME

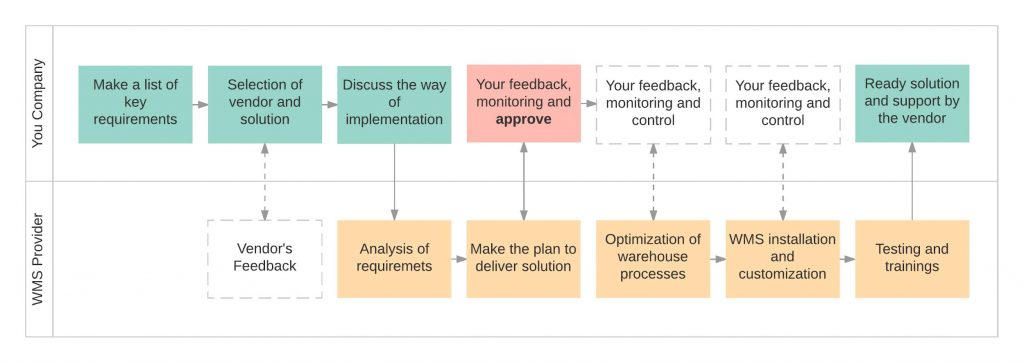

To implement the inventory management system, you need at least 2 participants. It’s you (green processes) and your WMS provider (yellow processes).

1. Set up an internal team: business owner (BO), warehouse manager (WM), 2 key warehouse workers (WWs)

2. Identify operational issues, warehouse and business problems, existing bottlenecks and weaknesses of current processes

3. Consider opinion of everyone in the team. For example, BO expects beautiful reports, WM wants to have auto-procurements, WWs want to reduce mistakes during the picking process, etc.

4. Make a list of current equipments (RFID / barcode scanners / printers) to include or replace part of them in the future system

5. Make sure everyone in the team understands the requirements, has the same expectation from the future solution including budget and lead time

Make sure you can explain your current workflows and goals as easily as possible. Providers will help you design a flowchart of processes to understand your business and goals better, but you can create a simple one by yourself. A picture may tell more than a million pages of text. Your goal is to describe the problem, the vendor’s goal is to choose what your business needs and how to improve the processes.

Focus on current problems you are facing and would like to solve and make a list of processes you are going to cover. Your goal is to have a clear view of the picture. Only when you get a full picture of the system, you can move to the next step. Choosing WMS as your new solution.

You can read more about creating requirements specification here:

Source 1: https://www.atlassian.com/agile/requirements

Source 2: http://intersog.com/blog/tech-tips/how-to-create-project-requirements-specification-that-any-provider-would-love/

3. Choosing WMS and vendor

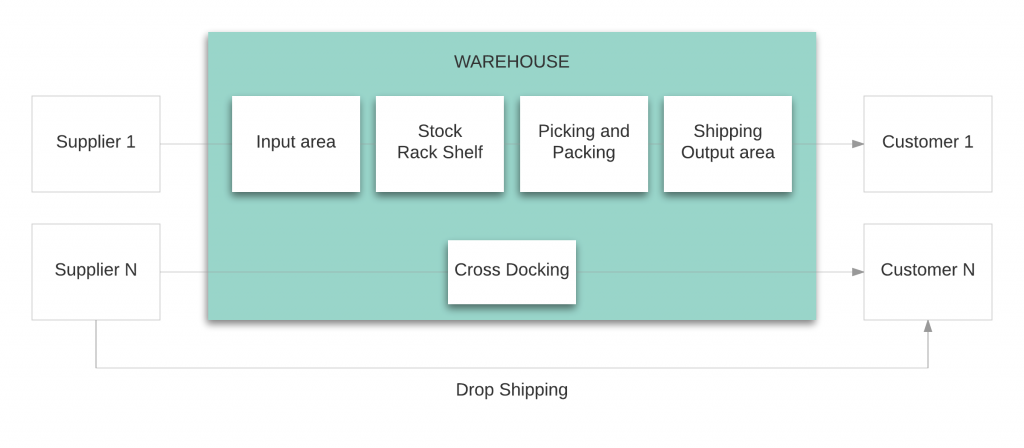

3.1 Overview of warehouse processes

Basic WMS / Inventory management system has to cover a few standard WH processes. At this stage, you simply need to check them and compare to your internal processes to see the gaps. Keep in mind that if you have nonstandard steps you need to be ready for internal revision of processes or additional customizations that can cost you a lot of resources.

Typical warehouse workflow

– Goods receipt (quality control as option)

– Putaway

– Stock and inventory management

– Picking

– Packing (labeling as additional option)

– Shipping

– Cross Docking / Drop Shipping

As option providers can add to the solution

– Barcode scanners / Mobile computers

– Label printers / Warehouse equipment integration

– Integration with suppliers and delivery services (FedEx, UPS…)

– Inventory reporting and analysis

3.2 Types of WMS providers

There are thousands of WMS / Inventory Management software solutions in the world. We’ve categorized them into several groups with links and examples to provide simple vendors overview.

3.2.1 Supply Chain Systems

Supply chain solution covers all processes from purchasing/manufacturing product to delivery to end-customers. That includes: manufacturing, transportation management, procurements etc. It’s a more complex and powerful solution than warehouse management software. In most cases, this is perfect for huge companies that have a complex network of logistics.

https://www.freightview.com/

http://www.made4net.com/

http://www.infor.com/

3.2.2 Ecommerce + WMS

Simple and modern warehouse management systems are part of the most popular ecommerce CMS like Magento, Prestashop and Shopify. Additionally, it can be synchronized with Ebay, Amazon and other external e-shops. It’s a good choice for small retail companies.

https://www.tradegecko.com/

http://www.stitchlabs.com/

http://www.orderhive.com/

3.2.3 WMS + Barcode Scanners

Typical WMS / Supply Chain management solution is already integrated with hardware equipment like barcode scanners and mobile computers / label printers / RFID tags etc. This is a good choice for big warehouses where main processes are based on internal warehouse operations (receipt, picking, shipping).

https://www.waspbarcode.com/

https://www.asapsystems.com/

https://ventor.tech/

3.2.4 WMS as a part of ERP system

Classic all-in-one solution. WMS module is just one part of the system. ERP allows to include other modules such as Finance (to prepare tax reports and manage cash flow), Sales (to sell goods through regional dealers), HR (to control timesheets of employees) or Reporting (to make finance and performance reports for management). This solution is the most comprehensive, but also the most expensive one.

This group is a perfect choice for medium to large enterprises. Most ERPs are based on modular architecture and might be the right solution for small companies as well. You can use WMS as a part of ERP and then add new modules to make your solution scalable and avoid extra costs.

https://www.odoo.com/

http://www.exactmacola.com/

http://go.sap.com/

3.2.5 Industry solutions

This group includes specific warehouse solutions based on customers’ industries and processes. For example, 3PL companies, Healthcare, Automotive, etc. This solution has been already preconfigured to a particular industry to provide you with the system ASAP. This is a good choice for SME, but keep in mind that you’ll always depend on the provider and his support due to the highly customized industry configuration.

http://www.accellos.com/

http://3plcentral.com/

http://www.datexcorp.com/

3.2.6 Mixed solutions

The most popular group is a mixed solution. WMS and ERP systems become more simple. Small solutions start to include additional features like built-in accounting to compete with big providers.

So if your business is based on online sales, you don’t need to look at supply chain management software. However, if you have a large warehouse and you are going to increase picking speed, you may want to look at WMS/ERP solution with already integrated equipment. The summary of all groups is below:

| Solution | Industry | Size |

| Supply Chain | Logistic, Supply Chain, Transportation, Manufacturing | Small and Medium (Large) |

| Ecommerce + WMS | E-commerce, simple retail, companies that have a small warehouse | Micro and Small |

| WMS + Mobile Scanners | Retail, Wholesale, Healthcare, Engineering, Fashion, 3PL | Micro, Small, Medium (Large) |

| WMS as a part of ERP | Manufacturing, Retail, Wholesale, 3PL, Jewelry, any company where comprehensive solution is a must | (Small) Medium, Large |

| Industry solution | Based on industry specifics | All |

| Mixed solutions | Based on requirements | All |

3.2.7 Area of customization

Unfortunately, in 90% of cases, there is no way to cover all customer needs without customizations. That depends on your company processes, rules, flows etc. The goal of the vendor is to show to the customer a standard flow of the system. Any system can be adapted via customization. But the main rule is simple. The less custom code you have, less support you will need in the future.

The less custom code you have, less support you will need in the future Share on X

3.3 Desktop, Cloud, On-premise and Hybrid solutions

Another important point is choosing a platform for your future solution. We can define the 4 most popular ways to install the system:

Desktop solution can be installed on your PC (or Mac). You save money but have no remote access to the system. This is the most rare type of platform.

For Cloud vendor, the server is provided and maintained by the vendor and accessible worldwide. You don’t spend money for IT infrastructure, but get a flexible environment for your business. Vendor provides support and maintenance of the server. Cons are security and your data depending on how on your vendor. Also in most cases, you do not have access to the database and the code of the software, so you cannot move your data to another vendor easily.

On-premise means the software installation is in-house deployed on a server owned exclusively by you. Other computers can have worldwide access. The benefit is security and full control, but you should have a system administrator to maintain the server.

Finally, the Hybrid solution is a mix of cloud and on-premise types. It allows to connect infrastructure and applications between cloud-based and existing local system. The benefit is high level security. You can use external SAAS warehouse/supply chain solution but keep all sensitive data using internal infrastructure. Cons are high cost and complex management requirements.

| Platform type | ||

| Desktop | Easy installation on desktop computer | No remote access to the system |

| On-premise | Security and control | System administrator is required |

| Cloud | Maintenance and support of the server Work from anywhere Flexibility | Security Dependence on the vendor Lock of future customizations |

| Hybrid | Absolute security and flexibility of the cloud | Much more complex and expensive |

Solution by platform type

3.4 The recommended steps to choose WMS provider

1. Choose 5-7 WMS providers you like based on your specific process

2. Send them your requirements and detailed overview of your current workflow

3. First look at companies who replied to you within 24 hours

4. Schedule a meeting and ask about the demo

5. Look how the system can solve your most critical problems and for clarification during the demo

6. If you use quickbooks (or other 3rd party solution) as the accounting system make sure the warehouse system can be integrated

7. Find the most appropriate systems (cover most of your needs, have clear interface, already integrated with software you use)

8. Ask about price and lead time before making the final decision

You need to remember that in 99% of cases, you won’t find the ideal solution. But the goal is to cover as much of the processes as possible and have it out of the box. Don’t hesitate to ask the vendors to show you how the system will cover a particular process. An integrated solution costs a lot. You should be comfortable that you invest your money in the right hands.

4. Discuss implementation approach

It’s a separate but a very important stage of communication with potential vendors. Short to do list is the following:

1. Identify internal PM / Product owner (single contact point from your side).

2. The internal person (or even team) should know everything about the company and the requirements of WMS, its needs, expectations about the costs and definition of done.

3. Discuss communication channels, rules (meetings per week, response time, etc.)

4. Discuss the methodology of implementation, high level plan and steps you have questions about. Make sure vendors have strong understanding of the implementation processes.

5. Sign the project declaration. Make sure it covers the description of roles, the relationship between the parties, communications rules, delivery time / budget limits / phase and anything else that’s relevant.

The main goal at this point is to define details and put together a preliminary plan of the project. It might be a project declaration, definition of done, memorandum of understanding, etc. At this stage, it may be difficult to estimate the exact lead time and costs.

As experience has shown, customers often change their requirements during the implementation process. Customer adds new business changes, wants to integrate additional software or equipment after the project was started. Customer can even change the already delivered solution and justify it as “I imagined it slightly differently”. This is okay, but just look at these numbers:

“31% of all projects are canceled before they ever get completed

53% of projects cost almost twice their original estimates

80% of projects go over time / over budget / don’t deliver expected results”

— The Standish Group Report CHAOS

This is the reason why in the communication stage, the vendor can provide only the range of the project timeline and costs. In some cases, it will be enough to make a decision. The real cost after this discussion can range from a half to one and a half of the previous estimate. This means that if you get a quote for $50,000 the actual cost will most likely be between $25,000 and $75,000.

On the other hand, the customer always wants to know the final budget from the very beginning. Generally, the solution is a fixed price contract. The vendors know that the customer is not responsible for the risks. And usually, the price of this risk will be included in the final quote. That is why you will see “$75 000” and not “$50 000 + risks.”

So is it possible to provide a more accurate estimate for all parties? Yes, but only after the development of detailed functional and technical specifications. This process can take a lot of time (10% of all implementation). Also it’s a paid service.

Customers with high level of maturity will prefer and sometimes even insist on having a comprehensive analysis done before signing the contract. In this case, business analysis and development of specs need to be a separate stage of the implementation and can be done by a third party expert. Remember that If you are not ready to pay for the analysis be ready to pay twice for the happened risks.

If you are not ready to pay for the analysis be ready to pay twice for the happened risks Share on X

There are many more you can read about estimating project costs here:

Source 1: http://www.dummies.com/careers/project-management/how-to-estimate-project-costs/

Source 2: https://www.projectsmart.co.uk/estimating-project-costs.php

Beware of these solutions:

– A solution without analysis of your warehouse

– No structured plan of implementation

– No support or trainings

This solution will be okay in case of SAAS (for small companies with 1-5 users). Implementation of warehouse software is a complex process. It includes analysis, planning, consultancy and development phases. The provider should have sufficient experience and can solve most of the problems during the planning and consultation phase to avoid extra fees in the development.

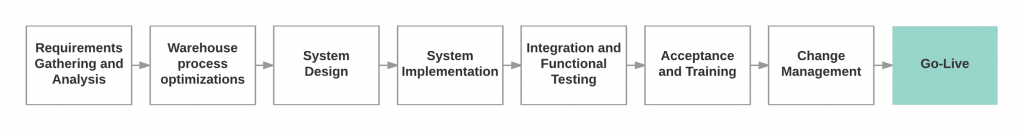

5. WMS deployment and customization

Once you have chosen a vendor and solution for your warehouse and find out the plan of implementation you are ready to move forward.

The biggest part (~50%) of WMS implementation takes analysis and modification of the warehouse processes. Look at the process distribution of WMS project. It shows that half the problems are solved before automation.

| Process | |

| Analysis of business requirements | |

| Developing a solution and recommendation to improve WH | |

| Optimization of warehouse processes | |

| WMS installation and customization | |

| Testing and training | |

| Other small things | |

| Total |

For some reason, there is a misconception that just warehouse management system will help establish order and prevent chaos in your company, but the system is only a tool. It’s important to improve your warehouse processes before you start to use the system. Otherwise, you may face more problems than before the integration.

There are several steps of system implementation described below. They are based on the best practices in warehouse management and automatization. Not all of them will be included in your plan. It depends on the particular provider and the specific tasks which the system must solve.

5.1 Requirements for Gathering and Analysis

You don’t start treatment until you know what is wrong, right? The doctor must examine you before he gets the right course of treatment. The same is true here. Analysis of the warehouse includes these steps:

5.1.1 Requirements Gathering

A process of collecting the user needs to solve a problem or issues and achieve an objective. If Requirements Gathering is not done properly, all next steps will be incomplete. No matter how good of a design it was. Requirements are the foundation for every project.

“The sooner you begin coding, the later you finish” – PM Humor

During this stage, an in-depth analysis of your business goals and problems should be performed and fully documented. Later, all this information will be included in “Project Definition” document. The purpose of this document is to provide an overview of the project and to promote a shared understanding before a more detailed Plan, Schedule, and Budget is prepared.

5.1.2 Requirements Analysis

During this step, the Analyst with the help of the Customer, will be taking the following steps (provided as an example based on Odoo WMS implementation plan):

| Type of WH analysis | Description |

| General warehouse analysis | The size of the warehouse, the interior of a zone, location of equipment, etc. |

| Analysis of customers and supplier orders | The number of lines in the order and volume of orders, the average values of the other order parameters and types of orders |

| Analysis of goods movement | Analysis of popular and unpopular products, how often particular products go into sales / purchase orders, goods balances |

| Analysis of warehouse activities | Analysis of sales and warehouse loading during a year / month / day / seasons and other variables |

| Analysis of types of warehouse activities | The analysis of the mutual localization of zones in the warehouse (receiving area, quality control area, picking zones, labeling etc.) |

| Analysis finance | Analysis includes staff salary, the cost of renting a warehouse, ROI, etc. |

The goal of this stage is to make a solid plan of warehouse optimization and find the most critical warehouse “blockers” based on all those parameters. Only such deep investigation of your processes can provide a full picture of the project.

During the analysis, the vendor should evaluate all the parameters of your warehouse:

– Identify and list your key end-to-end business processes

– Evaluate performance of the warehouse

– Analyse technology of goods movement

– Evaluate Picking time and speed

– Check accuracy of inventory control

– Evaluate warehouse equipment

Note that ignoring analysis of the warehouse will cost you a lot of money and may ruin the automation.

After this phase, both the Customer and the Vendor are on the same page about expectations of the project. The main output of “Requirements Gathering and Analysis” stage is “Project Definition” document that should contain the following information:

Business Problems/Opportunities

This section describes the problem or opportunity the project seeks to address using factual information.

Example:

Customer is working on low margin market of Electronic Appliance Distribution. Profitability of Business depends on:

– turnover of goods

– delivery time

Customer is expanding its partnership network of Suppliers and adding new physical stores and renting a bigger Warehouse to be able to have more goods in stock for same day availability.

Business Goals

This section describes the goals Customer is planning to reach after the completion of the project. Successful project completion does not directly guarantee that business goals are met. Business goals are out of control of the Vendor.

Example:

300% growth in turnover is to be reached in 2 years, while increasing expenses by a maximum of 50%

Project Goals

This section describes the background and context for the project and why it is being undertaken and speaks to the business value of the work being performed. Project Goals should be connected to Business Goals.

Example:

Streamlined Warehouse Operations / Capacity for Multi-Warehouse Operation to be able to handle high-load and control inventory.

Project Objectives

Objectives are statements that describe what this project will achieve and deliver. Objectives should be “SMART”: Specific, Measurable, Achievable, Realistic, and Timebound. To be specific and concrete, objectives should be deliverable-based. The completion of an objective should be evident through the creation of one or more deliverables.

Example:

Streamline warehouse operation and improve all warehouse processes achieving faster output, 100% traceability of actions and acquire capability to scale up the business infinitely:

1. Reception and pre-sale Product information in a system

2. Picking from Stock to Output process using a scanner

3. Labeling, Pack and Delivery process using a scanner

4. Inventory analytics

5. Ability to clone warehouse setup / scale up to a large warehouse within a minimal timeframe

Project Scope

This section is where you clearly define the logical boundaries of your project. Scope statements are used to define what is within the boundaries of the project and what is outside those boundaries. Examples of areas that could be examined are data, processes, applications, or business areas. The following types of information can be helpful:

– The types of deliverables that are in scope and out of scope (business requirements, current state assessment)

– The major life-cycle processes that are in scope and out of scope (analysis, design, testing)

– The types of data that are in scope and out of scope (financial, sales, employee)

– The data sources (or databases) that are in scope and out of scope (billing, general ledger, payroll)

– The organizations that are in scope and out of scope (human resources, manufacturing, vendors)

– The major functionality that is in scope and out of scope (decision support, data entry, management reporting)

Also in this section we describe:

1. Deliverables Produced – should be a clearly and understandably specified list of deliverables that are expected after project execution.

2. Organizations Affected or Impacted – specify areas or groups affected by, or that may participate in, the project. This is meant to be comprehensive but high level. Individual names should not appear, but the organizations they represent are included here.

Example:

In Scope

– Integration with barcode scanner for picking process

– Integration with label printer to be able to print UPS/FedEX labels

– Magento based Website for selling goods online

– Integration with e-Bay

Out of Scope

– Accounting Data migration

– Bookkeeping

– Integration with QuickBooks

– Integration with Amazon

Deliverables Produces

– Magento-based Website: search electronics by certain criterias (type, model, price, name)

– Magento-based Website: quick order allowing entering customer contact information payment with PayPal/CreditCard

– WMS ERP: Integration with Magento website to create jobs for Warehouse workers to deliver goods

– Integration with QuickBooks to automatically post information about Customer invoices from WMS ERP to Quickbooks account

Organizations Affected or Impacted

– QuickBooks – for bookkeeping, integration should be done with WMS ERP to transfer invoices in automatic way. From QuickBooks financial statements will be generated.

– eBay – automatic posting of Products and Stock On Hand should be performed to eBay from Magento. Sales Orders should automatically go back from eBay to Magento.

Project estimated Effort / Cost / Duration

The estimated effort hours and project costs may be depicted in many ways, including costs by team member, cost by deliverable, cost by milestone, or cost by category (internal labor, external labor, travel, training, supplies, etc.). Also include a chart showing the project start date, major milestones, and end date. The deliverables included in this milestone chart should all have been described in the scope section.

Note: Cost can be different in comparison to cost that was announced during pre-sale of the project. If customer is not satisfied with price after analysis was performed, than Project Scope above should be revisited to correct expectations of customer.

“Cost can be different in comparison to cost that was announced during pre-sale of the project. If customer is not satisfied with price after analysis was performed, than Project Scope above should be revisited to correct expectations of customer”

Project Assumptions

Project assumptions are circumstances and events that need to occur for the project to be successful, but are outside the control of the project team. They are listed as assumptions if there is a HIGH probability that they will in fact happen. The assumptions provide a historical perspective when evaluating project performance and determining justification for project-related decisions and direction.

Certain assumptions and premises need to be made to identify and estimate the required tasks and timing for the project. Based on the current knowledge today, the project assumptions are listed below. If an assumption is invalidated at a later date, then the activities and estimates in the project plan should be adjusted accordingly.

Example:

Customer will move to a new Warehouse of 30 000 sq. ft. on 31 of December, 2016. Customer will purchase 5 Zebra scanners 3 months after the project start date.

Project Risks

Project risks are circumstances or events that exist outside the control of the project team that will have an adverse impact on the project if they occur. (In other words, whereas an issue is a current problem that must be dealt with, a risk is a potential future problem that has not yet occurred.) All projects contain some risk. Risks may not be eliminated entirely, but can be anticipated and managed, thereby reducing the probability that they will occur. Risks that have a high probability of occurring and have a high negative impact should be listed below. Also consider those risks that have a medium probability of occurring. For each risk listed, identify activities to perform to eliminate or mitigate the risk.

Example:

| 1. Integration with Quickbooks requires development on Quickbooks side | - Start communication with Quickbooks at the earlier stage of the project to push development - Allow temporary workaround to export from ERP WMS and import in Quickbooks manually |

|

| 2. No USA accounting expertise | - Find local accounting consultant | |

| 3. ... |

Project Approach

This section is used to describe how the project will be structured and the important techniques that will be utilized. The project approach is intended to encourage the project manager to think about the project from the top-down instead of the traditional bottom-up. Including the approach in the Project Definition compels the project manager to both consider the dependencies of the project, and to incorporate the project management necessary to plan and manage the project.

Example:

Deliverables will be divided in Sprints. Outcome of each sprint in fully functional deliverable/sub-deliverable. Each Sprint will be no longer than 2 months. Planning of the next Sprint is happening 2 weeks before end of previous Sprint.

Project Key Members

It is important to understand who the major players are on the project. An organization chart works well. Otherwise, list the major project roles and the actual people involved.

Example:

Project Executive Sponsor: …

Project Sponsor: ….

Project Director (Manager of the Project Manager): …

Steering Committee Members: …

Project Manager: …

Client Project Manager: …

Project Advisors: …

Project Team Members: …

It is important to note that this document will contain Customer’s understanding of Requirements/Steps and Goals. This will help the Business Analyst to suggest best possible solutions that will help to achieve customer goals. Also it will help avoid misunderstandings.

No further steps should be taken until Project is well defined.

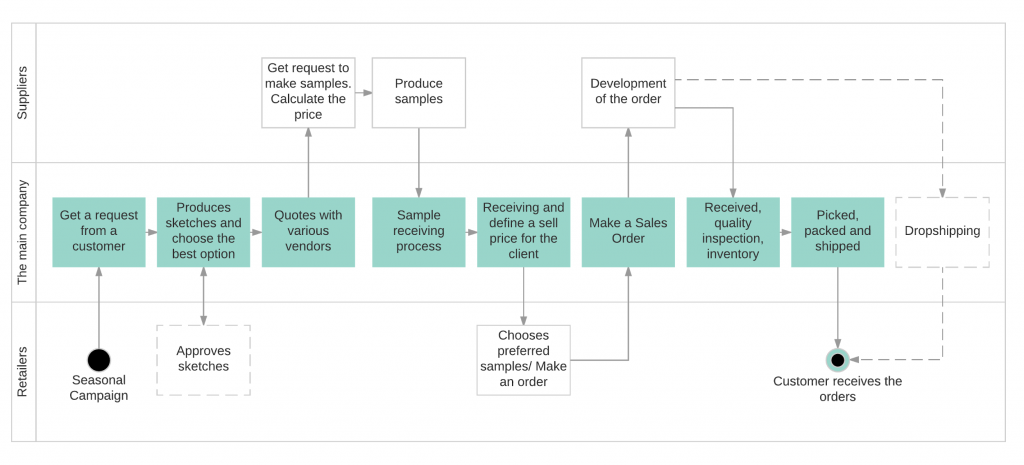

5.2 Warehouse process optimizations

The current step does not yet include any software implementation.

Your service provider will conduct a complete analysis of the activity of warehouse. The next stage includes improvements of:

– Warehouse space, zones, areas, racks, etc. (space optimization)

– Goods receipt and putaway processes (cross docking and dropshipment)

– Storing and goods moving routes (pallets, boxes, special packaging)

– Picking (picking waves/batch pickings, optimization and simplification, order segmentation)

– Shipment (packaging, weight, combination of orders)

– Staff management (motivation, working time control, managers vs workers)

– Warehouse equipment (scanners, printers, robotic racks, shelves and other)

The improvements of these processes allow to minimize customizations of the system (as well as its costs). Remember the goal of vendor is to optimize warehouse processes to make your business more effective. The final aim is get a solution based on world-class warehouse standards that should effectively solve your problem.

Let’s make a checkpoint. Analysis and optimization processes take more than 40% of the time. The vendor defines main problems, discuss them with you, and you make analysis and optimize the processes (again together with your internal team and after approval of key stakeholders). This stage can be on-going throughout the next phases as organizational improvements may be required also during deep analysis and system design. But the main parts of optimizing and understanding your business are already done.

You can read many more about warehouse process optimizations here:

Source 1: http://www.stitchlabs.com/ultimate-guide-to-scaling-your-retail-business/optimizing-warehouse-management

Source 2: http://www.investcalgaryregion.ca/blog/10-easy-to-implement-tips-to-improve-your-warehouse-management-process

Source 3: http://www.inboundlogistics.com/cms/article/optimizing-warehouse-operations/

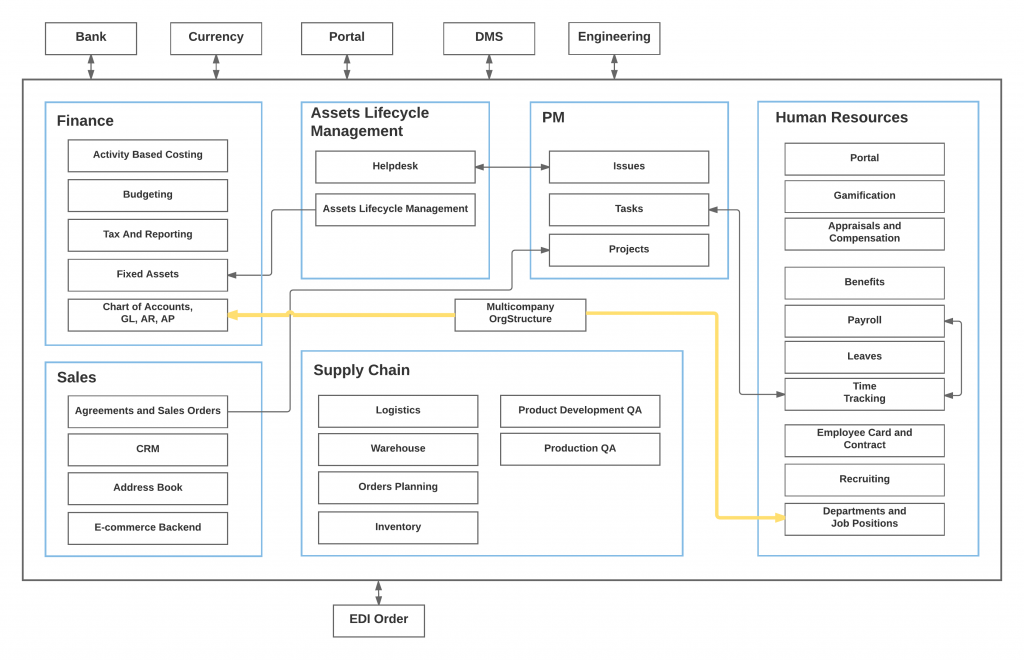

5.3 System Design

At this stage, we assume that we already have well-defined business requirements that we need to close and have an understanding of systems that will be involved in implementation and that are required to reach Business Goals. Now it is time to dig deeper into technical aspects.

5.3.1 System Architecture Design

First of all, we need to define how your systems will interact with each other and what systems will be involved. Usually, it is a document with a header that contains a big image (see below example) and text that is describing each node and each arrow.

5.3.2 Gap Analysis

Once all nodes are defined, it is time for the Business Analyst and the Technical lead to analyze every system that is involved in the process and to evaluate it against business requirements. As a result of this, list of gaps between the requirements and selected software are defined.

5.3.3 Scope of Work (SOW) Creation

Based on System Architecture, Gap Analysis and Business Requirements – Scope of Work (SOW) document is created by BA. Based on quick discussion with technical lead BA fills in rough estimations for every line in this document to give Customer an understanding on approximate cost of Implementation. At this stage Customer is getting the most appropriate understanding of the budget needed for the project and can review priorities (remove or add lines to scope). Note that typically during this step, a lot of cases will be uncovered that the Customer was not even thinking about originally. These can be put in the backlog for future Project Phases.

5.3.4 Functional Specifications

At this stage, every business requirement is divided into functional requirements. It is the responsibility of the Analyst to perform this task. Each case of improvements (gap), each feature of the future WMS should be discussed with the Customer, accepted and written by Business Analyst (BA) using technical language in the developer’s specs. Developers work using specs only.

5.4 System Implementation

5.4.1 Install WMS system

We have already discussed types of servers in the beginning of the article. The installation of the system can take from a few hours to a month based on requirements and customer size. This stage includes:

– Choosing virtual server

– Architecture design. IT infrastructure (servers, load balancing, etc.)

– Servers configuration and security settings

– Installation of WMS system

– Setup access, testing

After this stage, you get an access to your new “clean” WMS system from anywhere in the world. Note that if you rent the server (amazone, OVH, digital ocean, etc.) you need to have an admin in house, or ask the vendor (or hosting provider) to provide you maintanance at-least on monthly basis.

5.4.2 Design virtual WH

The first step in the new system. Developing virtual warehouses / zones / locations / racks and rows based on real warehouse plan. At the end of this stage, we have to get an exact copy of a real warehouse inside the system.

5.4.3 Mandatory customizations

There is no solution that will fit your needs 100%. That is the reason why customizations will always be required. Your products can have specific fields, your processes can be different compared to the industry. At this stage, the provider makes mandatory customization when it’s impossible to continue implementation without it.

5.4.4 Import customer data

Employees / goods / customers / suppliers / users etc. Uploading and migration of all your data. Note that the stage includes settings of business roles, user access rights, groups, etc.

5.4.5 Make initial inventory

At this stage, we allocate all products in the real warehouse to locations in the virtual one (initial inventory). As a result, we have a complete copy of all products with correct quantity on hand.

5.4.6 Sales and procurements rules

This stage includes setup of procurement and sales rules (based on requirements), reordering flow + all other things that should be implemented.

5.4.7 3rd party software integration

Includes integration with external software (or internal in case of ERP) like Accounting (Quickbooks) / CRM (Salesforce) / Marketplaces (eBay) / Shipping companies (Smartfreight), etc. Based on complexity can be delivered as separate stages of the project, after WMS goes live.

5.4.8 3rd party hardware integration

The same regarding warehouse equipments. Integration with barcode scanners / printers and labeling system, etc. In most cases, modern WMS solution includes integrations with some hardware and software solutions. Make sure you made the right choice to avoid unnecessary integration or extra features.

5.4.9 Additional customizations

It includes other customizations based on customer’s initial requirements that were not so important to implement before. Discuss the feasibility of extra customization with your provider. Sometimes it’s better to change processes than to customize the system and avoid unnecessary costs.

5.5 Integration and Functional Testing

Integration testing is testing more than one component and how they function together. For instance, this may involve looking at how another system interacts with your system (Webshop with your WMS). Usually this requires a fully installed system, although in its purest forms it does not.

Functional testing is testing the system against the functional requirements of the product. Product/Project management usually writes these up and QA formalizes the process of what a user should see and experience, and what the end result of those processes should be. Depending on the product this can be automated or not.

At this stage, there is lots of communication and work happening between:

– Developers and Testers (regarding fixing found issues)

– Analyst and Developers/Testers (on requirements clarification)

– Analyst and Customer (communication on side cases that is not clear how to better handle from business point of view)

Note that tests are performed on special Development Environment that is not accessible by Customer. As a result of this stage, the Customer receives system that is installed on special User Acceptance Testing (UAT) environment.

5.6 Acceptance and Training

5.6.1 Acceptance Testing

After internal testing of the system is finished, all the functionality is moved to special environment that is called the UAT (User Acceptance Testing). This is an environment that is a copy of the future Production environment and is used by the Customer to evaluate all the features and provide feedback to the Provider before it is moved to production.

5.6.2 Training

Don’t count on free online documentation, make sure your vendor includes support / consulting and trainings in the provided solution. Ask the provider about all possible options and agree about trainings before starting the implementation. Above UAT environment is also actively used for trainings. Also as result of your provider’s work you should expect training videos/documentation.

5.7 Change Management

It is often assumed that if the Vendor performed Key Users training, that means that the Project is successful. But that is not correct! The typical situation is in which both the Vendor and the contact points from the Customer side do a really good job executing project. All was done according to the “Project Definition” (within time, budget and quality criteria), but… the Project fails because it is not accepted by end users! It is a typical situation with new systems when users are not willing to use it, or even claiming that the system is not usable even without trying to work with it.

Many Customers underestimate the value of “Change Management” step. However its improper execution may lead to failure of the whole project. And this will be not the Vendor’s, but the Customer’s fault.

Usually Change Management is responsibility of the Customer, not the Vendor. Vendor is training only key people who will be core of Change Management Team. Also Vendor guides Customer through process of Change Management. However, it is Customer’s responsibility to plan proper activities (based on recommendations and consulting with Vendor) for a successful rollout of the system.

Typical mistakes made during Change Management process:

1. Neglecting Change Management until the end

Change Management is actually a long separate project that requires its own project plan, team, budget. Start planning it in advance.

2. “Change Management” treated the same as “User Training”

This is a typical mistake. No user training can help to incorporate brand new system into an organizational structure. Especially if the organization has already existed for a long time.

3. Not defining Responsible parties for Change Management

There should be an internal lead/manager who will monitor/control/plan integration of the new system into the business. The New System is a new business project that requires its own Project Manager.

4. Going live without familiarizing users with system in advance

Do not leave the presentation of the system to end users as the last step. After each delivery organize an internal group that will be doing day-to-day operations in the new system. You will be surprised about their feedback.

There are many more you can read about here: http://www.uxcoxygen.com/news/19-signs-that-your-projects-change-management-is-in-danger

5.8 Go live

After Customer confirms functionality on UAT Environment it is all moved to the Production environment and the Customer is using it in day-to-day operations.

6. Post Go-Live support

Check that your provider has support packages. One of the reasons why the Customer is deciding to change the WMS is the lack of support of their system. There are no updates, no support, no opportunities to make new improvements. Do not repeat the same mistake twice.

7. Costs and lead time

According to the report from the Software Connect, WMS budgets increase with the size of the company.

The average cost for the WMS implementation is around 50K EUR.

It’s fair for companies with 10-25 employees. For 50+ employees the average budget can be around 100K EUR.

Based on our experience in Odoo WMS implementation we can define 3 groups of costs for SME:

| Type of system | Costs (average price) | Notes | |

| Cloud based and simple inventory management | 1-2 mo | Min: €20-€100 /mo Max: 1K-3K EUR/mo | SAAS solution, limited packages and specified solutions |

| Full WMS / Supply chain software | Min: €5K-€20K Max: €45K-€75K | Full license or monthly fee model + customizations |

|

| Full ERP / WMS implementation | Min: €15K-€35K (MVP) Average: €40K-€75K (light) Max: €100K-€250K (full) | Full ERP includes Accounting, HR, MRP, Sales, 3rd party integration etc. |

SAAS solution (Cloud-based WMS/Inventory management system) has the best price on the market. You don’t pay for the server either. Unfortunately, this solution can meet the needs of small companies only. There are a few vendors that provide SAAS packages for medium and big companies, but the monthly fee of the solution will be much higher (0.5K-3K EUR/mo).

The full WMS solution is a good choice where inventory management and logistic are the main processes. Sales, Accounting can be covered by other 3rd party solutions (Salesforce, Quickbooks, etc). Has the average price among other solutions and can fit medium and large enterprises.

ERP system that includes a WMS provides a full scalable solution. It allows to add new modules and processes gradually as your company grows. Also, this system can be completely modified to customer requirements. Finally, it allows managing risk, finances, handle people (HR) and control all aspects of the company using one single tool. It’s definitely a must have for medium and large enterprises.

As the most powerful solution, the ERP costs more than other ones. In case of full ERP integration, processes as Project Management, Communications, Testing, Training can take up to 25% of the implementation period.

WMS consultants have to help you find the optimal solution for your money and your needs. Good WMS provider can always explain what’s really needed for your company and why you need it.

Example

Company has 20-30 employees and 3 warehouses, 350 m2 | 350 m2 | 1500 m2 (total 2200 m2). The annual turnover is 4M. Currently, the company uses excel and papers to manage operations. The company is going to use mobile computers as scanners, optimal picking routes feature, manage HR and PM processes in the WMS, make monthly inventory in a day and integrate the system with Quickbooks and Magento online store + 3 local shops with POS. There are two options:

1. WMS based on ERP

2. WMS solution already including integration with mobile computers, QuickBooks, Magento and build in POS function

The choice depends on particular requirements.

1. The budget of the company ~ 100K. The goal for the next two years is to double the annual turnover, add reporting system and integrate WMS with 25 partners in 4 different countries. There is no solution on the market among WMS. In this case, the first option is prefered (ERP based system).

2. The budget of the company is limited. Additionally, there are a few solutions that cover 90% of the needs of the company. In this case, the second option is prefered (WMS).

Cost calculation by annual revenue

There is a method that can help understand the “limits ” of your IT budget. Generally, it’s 1-2% of the annual revenue of your company. If your annual revenue is 10M, then the budget between 100K and 200K is normal. It’s a rough estimate, but it helps to get an idea of the potential budget.

Related service – Estimate automation of your business

So the cost of implementation depends on many parameters like industry, numbers of warehouses/products, orders per day, employees, particular requirements, etc. In most cases, the cost of the implementation can be calculated after the deep analysis of the business only. However, the budget limit must be agreed upon with the vendor in advance.

8. Summary

We hope this article helped you understand the project sequence and basic steps that you will face during the warehouse system implementation.

Remember that the only thing you should keep in mind is the result. Every business needs to have effective tools to manage processes, staff, time and money to grow quickly and effectively. The system should be a good investment. Otherwise, it doesn’t make sense to start implementation of a new software.

Complete a short survey to get your inventory automation quote

Our thanks

We want to say thanks for all who helped us to create and review this guide. The main reviewer and consultant is Alla Lenskaya (Head of SAP BI department at International IT company). Additional thanks for Eva Pinter (SAP Expert at YBO Services Ltd) and Habila Ayakpat (IT Business Analyst at LafargeHolcim).

Welcome to colaborate

We are open to feedback from experts to improve the article. If you are similar to WH / Inventory process or have a good experience in project implementation, we look forward to your feedback. Add your comments or drop us a mail to become a new reviewer or co-author of this or future articles.

Links and sources suggested to read:

http://www.softwareadvice.com/

http://www.supplychaindigital.com/

http://www.warehouse-logistics.com/

http://www.positivevision.biz/

http://www.slideshare.net/

http://www.camcode.com/

https://docs.oracle.com/

http://www.motorolasolutions.com/

https://www.prosci.com/

2 Comments

MDAP

"31% of all projects are canceled before they ever get completed, 53% of projects cost almost twice their original estimates 80% of projects go over time [...]". The harsh reality, it's hard to plan everything perfectly, perhaps that's why more and more executives are comfortable with the Agile project management model.

Congratulations, it's a great guide!

inventrax

you have given a great insight into wms for customer selection and approach for customers