Every year thousands of business owners have to decide whether a new Warehouse Management System is the right decision for their company. Integration of new software takes money, development time, and consulting, but the benefits are not immediately clear.

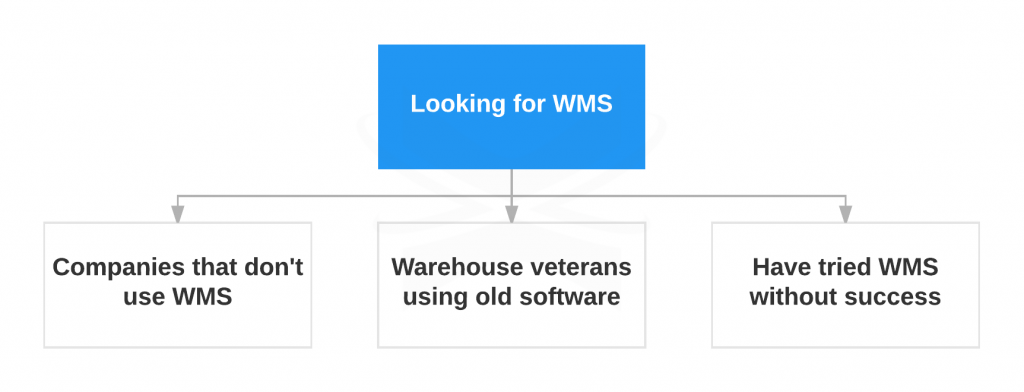

Who is looking for the new WMS solution?

If you are looking for a new WMS or Inventory Management System, it is likely that you are in one of these 3 groups:

- Fast growing business without WMS system (you are using excel or just paper)

- Warehouse veterans using the software from 1985 to 2000

- You have already tried warehouse system, but it did not help

If you are in the first group, your company has no defined processes, but you are ready for a change.

The second group has a good understanding of warehouse processes and WMS itself, but is blocked by the old system without support or upgrades.

If you are in the third group, you believe that the system didn’t allow you to achieve the desired results or worse, resulted in project closure for example. Some of you may have stopped using the product and continued to search for new systems.

Does your company belong to one of these three groups? If yes, here is what you need to think about.

Is it a good time to integrate WMS (Inventory Management)?

You may need a new WMS, if

- You cannot deliver goods within 24 hours after receiving the orders (>10% of all cases)

- You have incorrect items or missing ones during the shipping / picking process

- It’s difficult to generate pick lists using your current system

- You can’t keep track the correct number of goods in the warehouse

- You receive customer complaints regarding slow shipment

- It takes a lot of time to find out when and what arrives to the warehouse and what order it belongs

- It takes a lot of time to find out where products are located and where you should go to find the next item

- You can’t assign the storage location right away during the receipt process

- You are going to increase sales in several times (open new market / shop)

- Your system doesn’t have features your competitors, e.g., customization is costly

- There is no support for your system or you are the only one who supports it

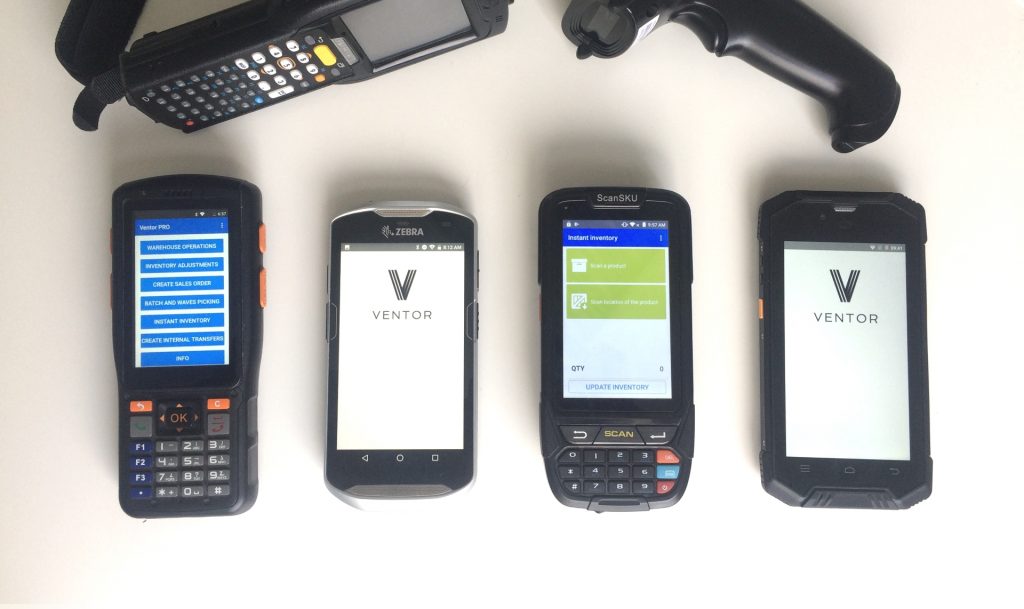

- Your system cannot be integrated with suppliers / 3rd party solution (accounting), 3rd party hardware like barcode scanners / label printers

- You have to gather 4-10 orders at the same time (picking waves)

- You are going to use RF Scanners / RFID tags

The checklist doesn’t cover all points but it contains most critical issues in order to understand the current state of your warehouse. The main thing that combines all these points is control.

If you aren’t faced with these points, you can continue to use your current system. Let’s be honest, the vendor is to sell you a system, but your aim is to buy WMS only when you need one. If you can control all processes on paper/excel, then why should you change it? You don’t need an umbrella if you live in the desert, right?

Let's be honest, the vendor is to sell you a system, but your aim is to buy WMS only when you need one Share on XWhat WMS solution providers are saying?

If you search for “WMS solution” or “Inventory Management System”, you will find many offers from hundreds of providers. Here are the top 5 points to consider:

- Automation of routine work (reordering rules, multi ordering, inventory, monthly reporting, etc.)

- Monitoring and controlling management, making main processes more transparent

- Increased speed (lines per hour) and higher quality (reduction in errors of all operations)

- More productivity with the same staff / resources

- Connecting to other business systems (E-commerce, POS, Accounting, and Reporting)

This list may seem to imply that we should install WMS immediately. However, there is a time for everything. WMS integration should be implemented when it is time to do so. You don’t buy a bike for your one year-old child, because the baby must first learn how to walk.

WMS integration should be implemented when it is time to do so Share on XFirst optimization, then WMS

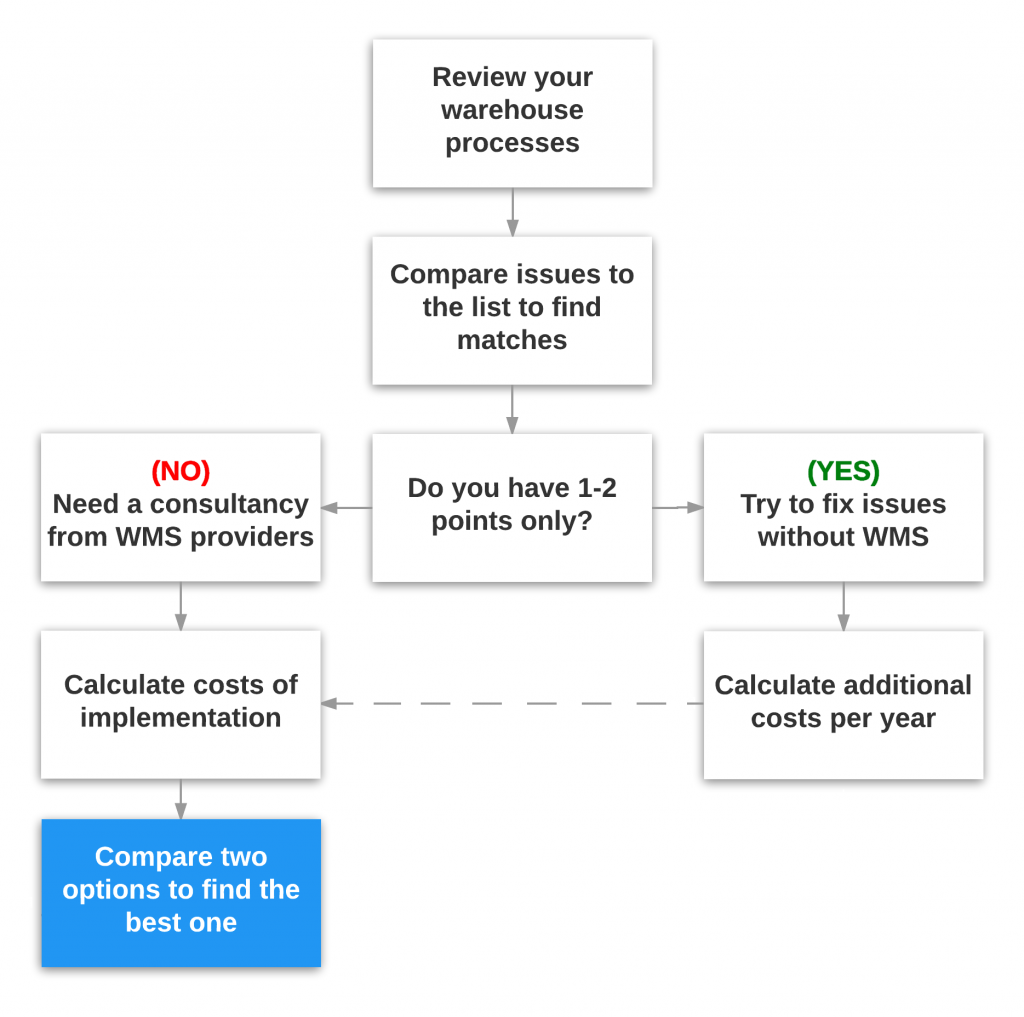

- Review all processes from the moment you receive a new order to the shipment from your warehouse

- Make your own list of issues

- Figure out the main problems and compare to our list to find matches. If you have 1-2 matches, then go to the next point

- Is it possible to fix these problems without WMS / Inventory system? Perhaps another worker or new shelves for storage of goods will be enough to cover all your needs for now

- Calculate additional costs to fix issues. If you already have such a budget, schedule the upgrade

Do you have more than 3 matches? Then you may want to consult 5-7 companies and describe them your problems. If they have a solution to cover your needs, then scheduling a demo may be a good idea.

Compare the costs of equipment rental, employee’s salary, etc. per year to cost of implementing WMS. If WMS allows for solving the issues at the same cost, then it may be a better solution. If the costs of integration are too high compared to additional expenses, then is would be better to postpone implementation.

Conclusions

Technically, WMS can be integrated at any moment. The main problem of WMS is the integration of all processes before implementation. For some reason, there is a misconception that any system (WMS / ERP / Inventory Management) will help establish order in the warehouse and prevent chaos.

The system is only a tool in the hands of the user. If you have problems in the organization of the processes, you will bring more chaos than before the WMS…Think about it and be ready before you start spending your money.

Leave comments to share your experience when it’s time to look at WMS.

Related post – Ultimate WMS implementation guide for SME

- 3+ years of experience in product manager and product owner roles

- 6+ years of experience in sales and offline and online marketing

- 5+ years of experience in web and mobile project management

- 4+ years of experience in B2B marketing (IT companies, ERP systems)

- 5+ years of experience in warehouse management and logistics

- Main project roles: Marketing Manager, Project Manager, Product Owner, Consultant

- Primary objectives: Increase sales and brand awareness; implement marketing strategy; achieve objectives and goals.

----------------------------------------------------------------------

Education: Bachelor's degree.

----------------------------------------------------------------------

Experience:

Project Manager

Bookshop

Marketing Manager, Chief Sales and Marketing Officer

XPANSA Group

----------------------------------------------------------------------

Current position: Co-founder & CBDO

VentorTech

----------------------------------------------------------------------

Licenses & certifications:

IT Product Management (Basic Level)

IT Product Management (Professional Level)

My Monday

0 Comments