To ensure optimal functioning of your warehouse after a wms implementation, establishing a strategic warehouse mapping layout is imperative. A warehouse map is the fundamental tool that will help you accomplish this.

A map of the warehouse provides a visual layout representation highlighting the locations of products, storage areas, reception, control, packing, and delivery zones.

Goals

A warehouse map is an essential tool for managing many problems in a warehouse:

- allows increasing pick speed by reducing walk and lifting time

- allows allocating products strategically to maximize space utilization

- provides a base for building picking routes in your warehouse

- visually aids new employees’ orientation

All this results in the main business goal: minimizing delivery time, which makes business compatible for customers and reduces expenses on picking operations.

How to prepare a warehouse map

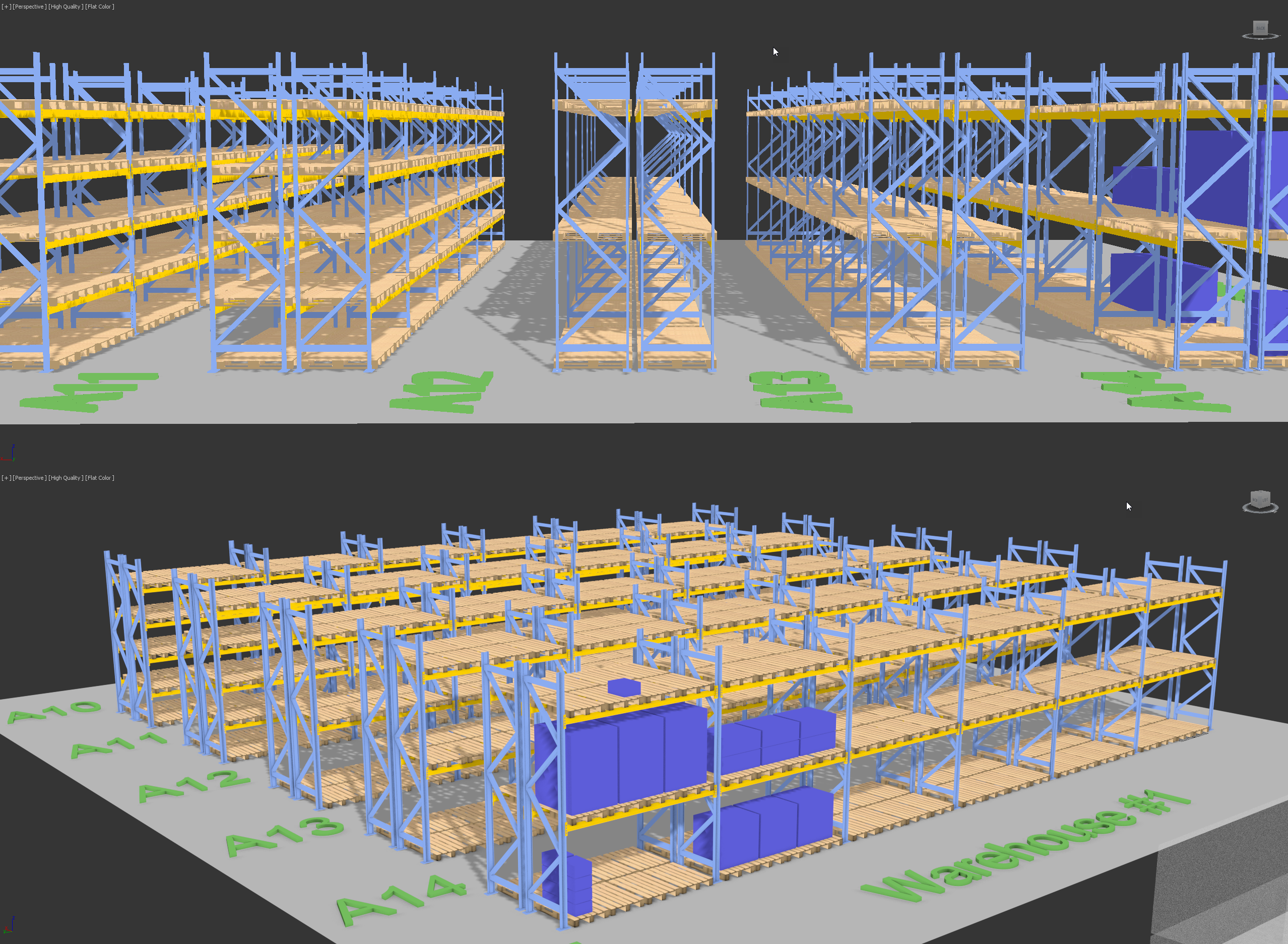

Assumption: In this article, we assume that you’ve already set up all the racks in your warehouse and you have a building or room fully prepared for items storage. Or, probably, you’ve been working with your current configuration for quite some time and now do want to make optimizations.

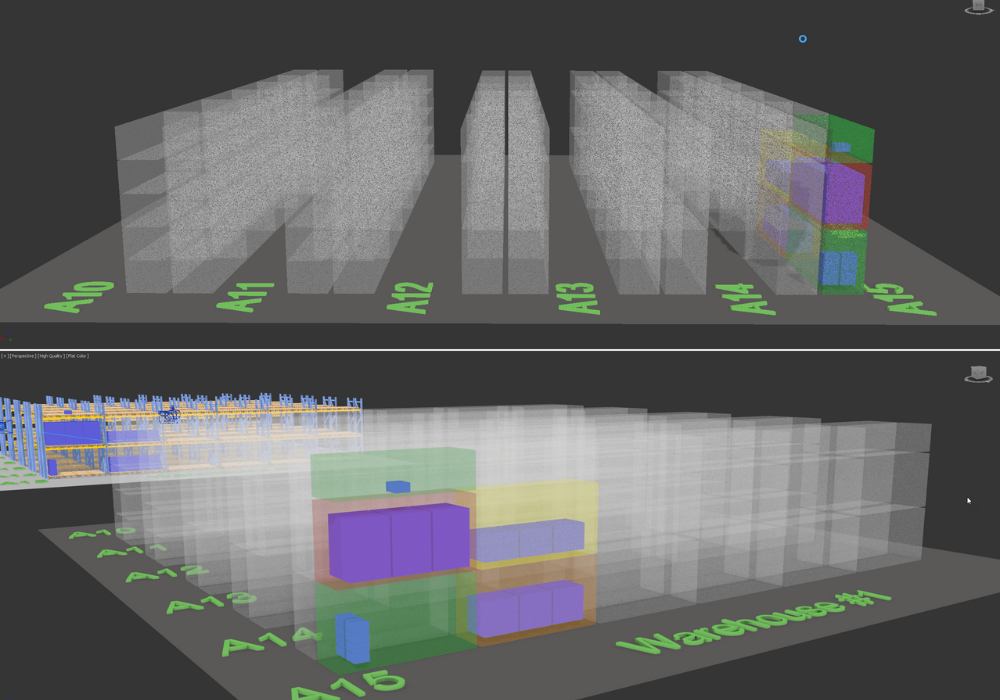

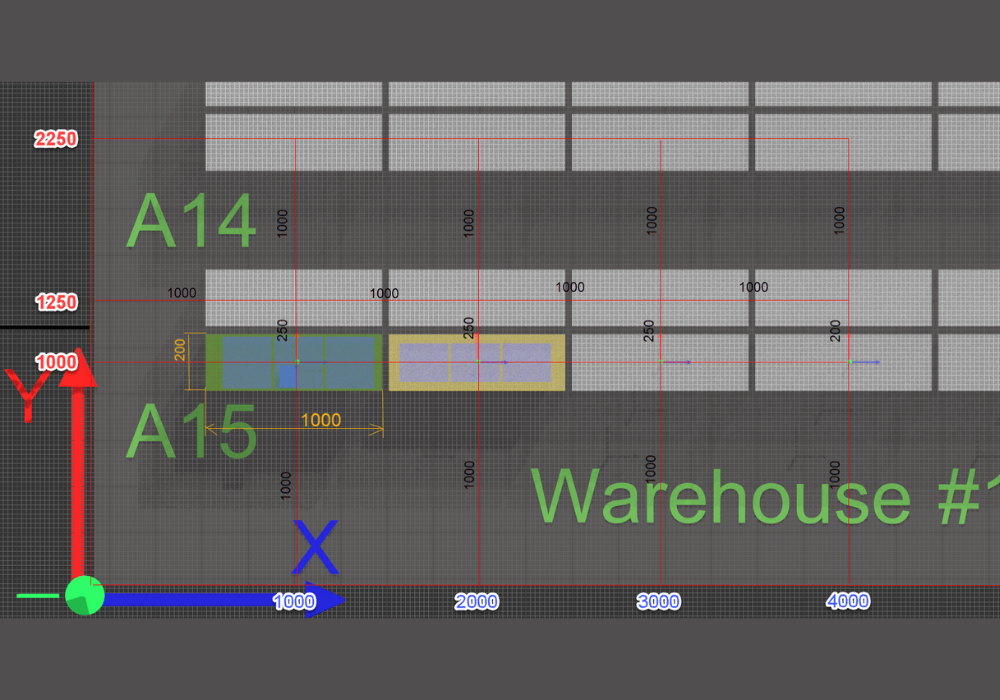

Rough scheme

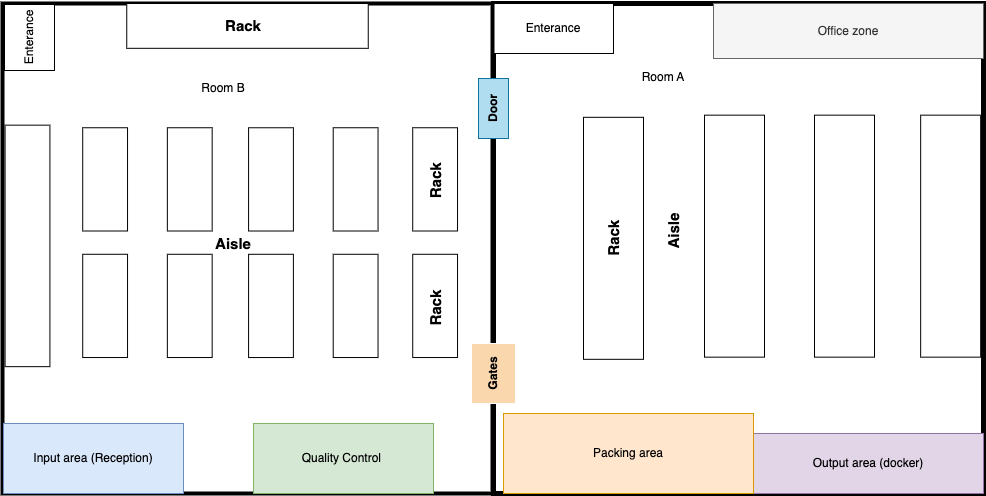

First, create a warehouse layout scheme. You can start with drawing it on paper or using a drawing tool.

Your scheme should show the basic warehouse zones and units: reception, production, packing, delivery zones, different rooms, racks, entrances, and aisles.

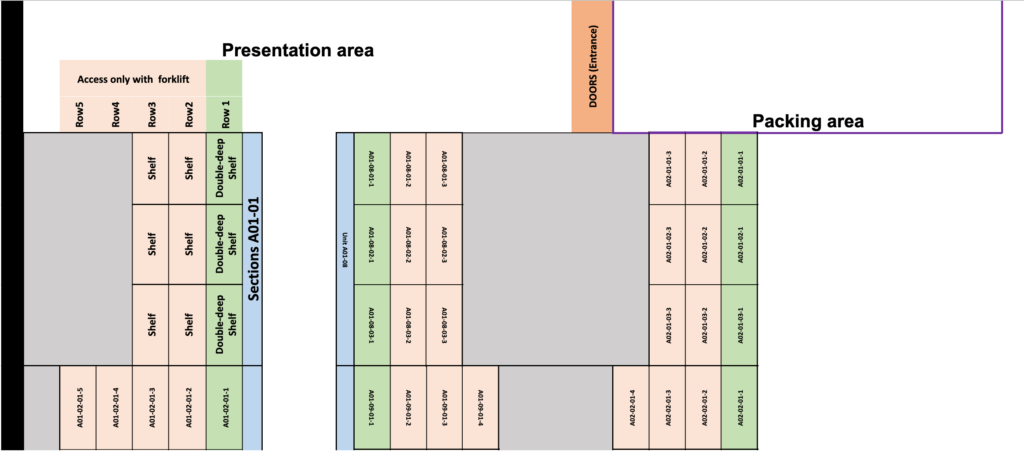

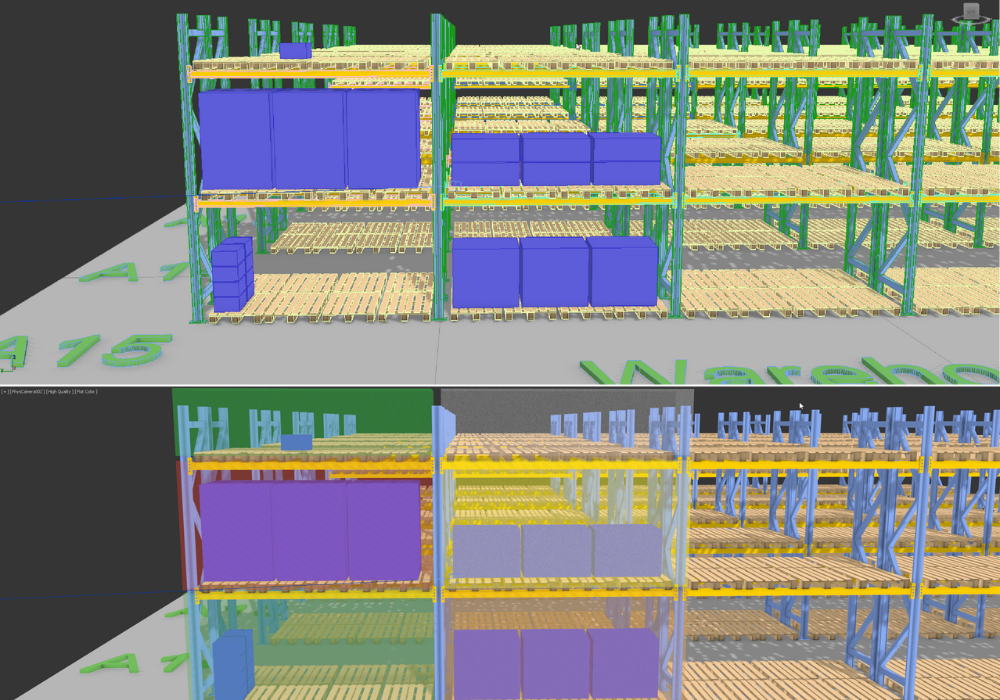

Specify Sections, Shelves, and Bins

Don’t forget to specify which shelves are accessible only with the use of ladders, forklifts, or special tools and double-deep locations. Such details affect the definition of optimal routes for pickers.

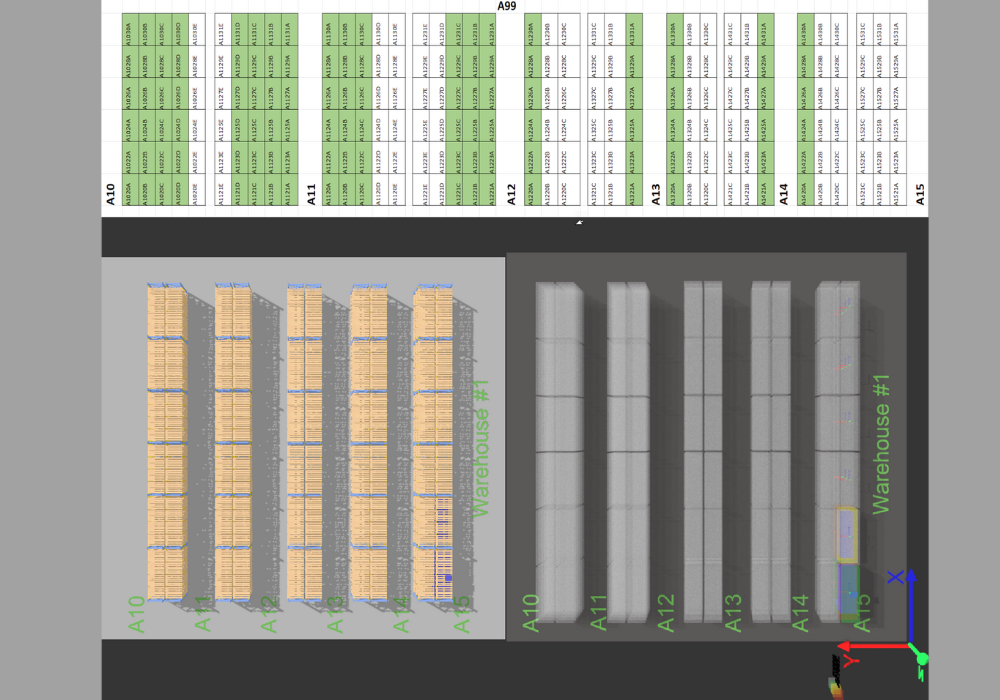

Name the warehouse attributes

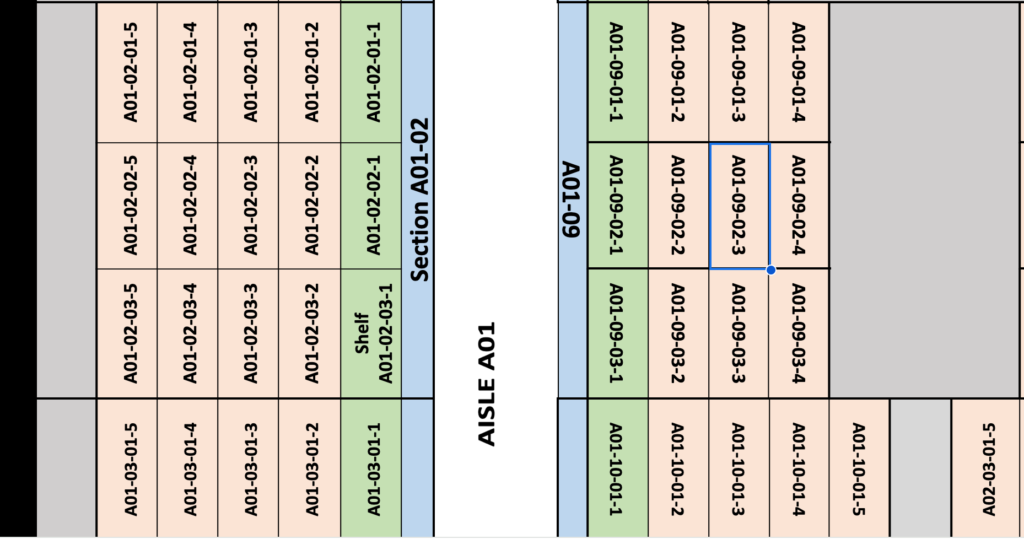

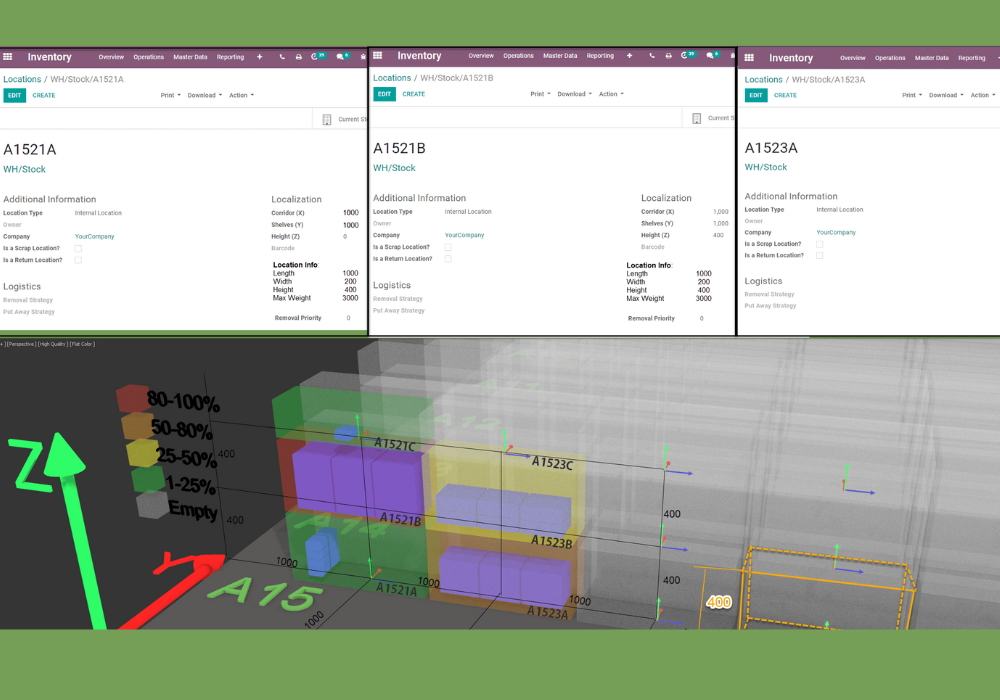

The next step is to name the warehouse attributes: racks, aisles, sections, shelves, and bins. Use a letters and numbers approach. First, name your aisles with a letters or a letter + number combination, such as, for example, Aisle A01. Then, name your sections as, for example, A01-01, A01-02, and so on. Then your shelves can be named with the aisle name, section name, and shelf name; for example: A01-01-01, A01-01-02, A01-01-03 . . . A01-09-02, A01-09-03, A01-09-04, and so on.

Make sure that each location has a unique name.

Useful link: How to name locations For a small shop

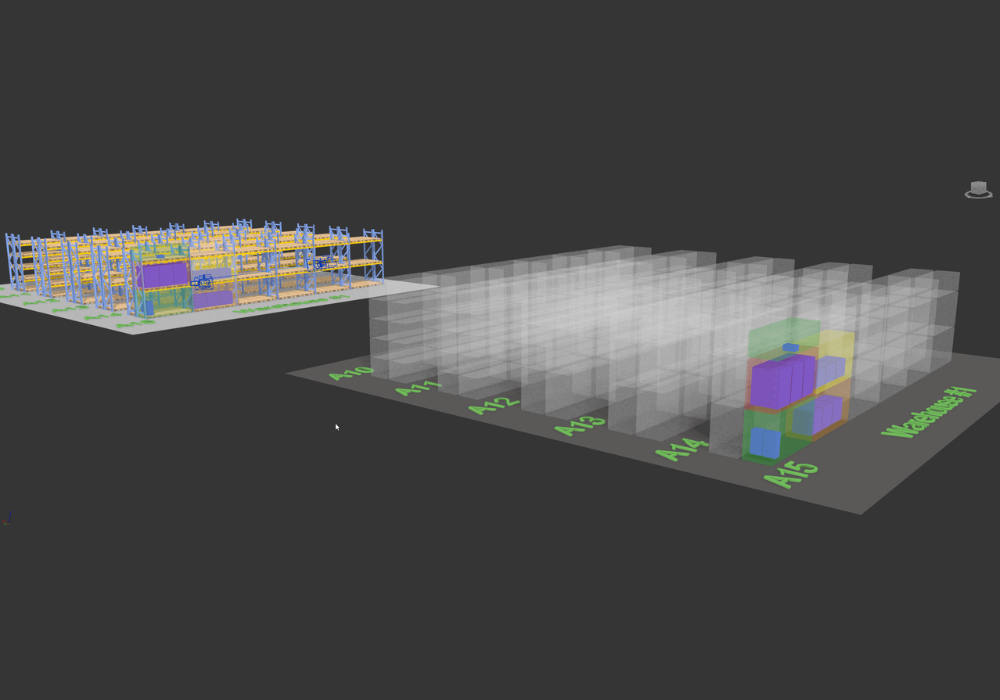

Upload the warehouse map in Odoo

After naming warehouse locations, they should be uploaded in Odoo.

First, enable Locations in Odoo. To activate locations, go to Configuration ‣ Settings and enable Storage Locations. Then, click Save.

After activation, Odoo, by default, will generate a Stock location for all your warehouses.

To build a correct hierarchy of locations, we suggest creating a first location manually and then exporting it to use the file as a template.

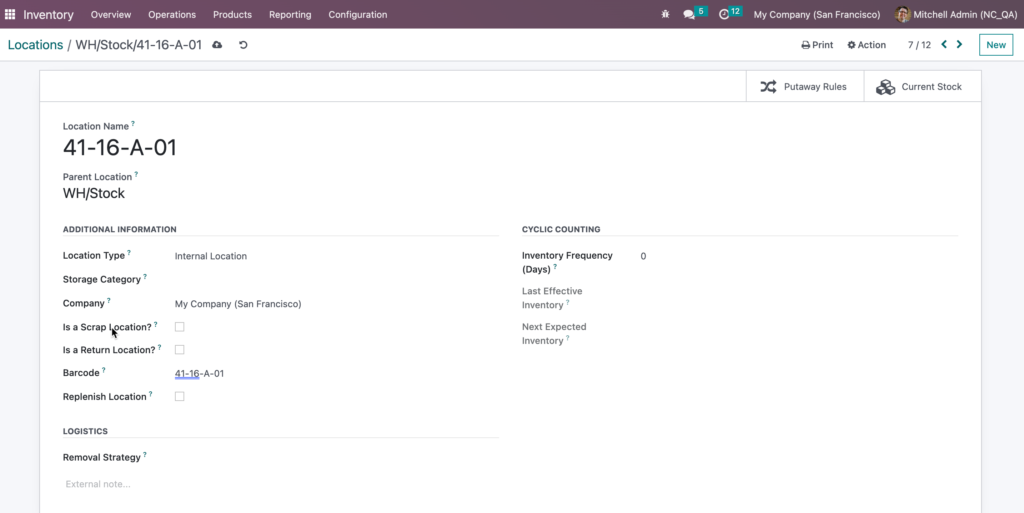

For example, create a location with the name 41-16-A-01. Then set a Parent location of WH/Stock, with the Location Type as Internal Location, and with Barcode as 41-16-A-01.

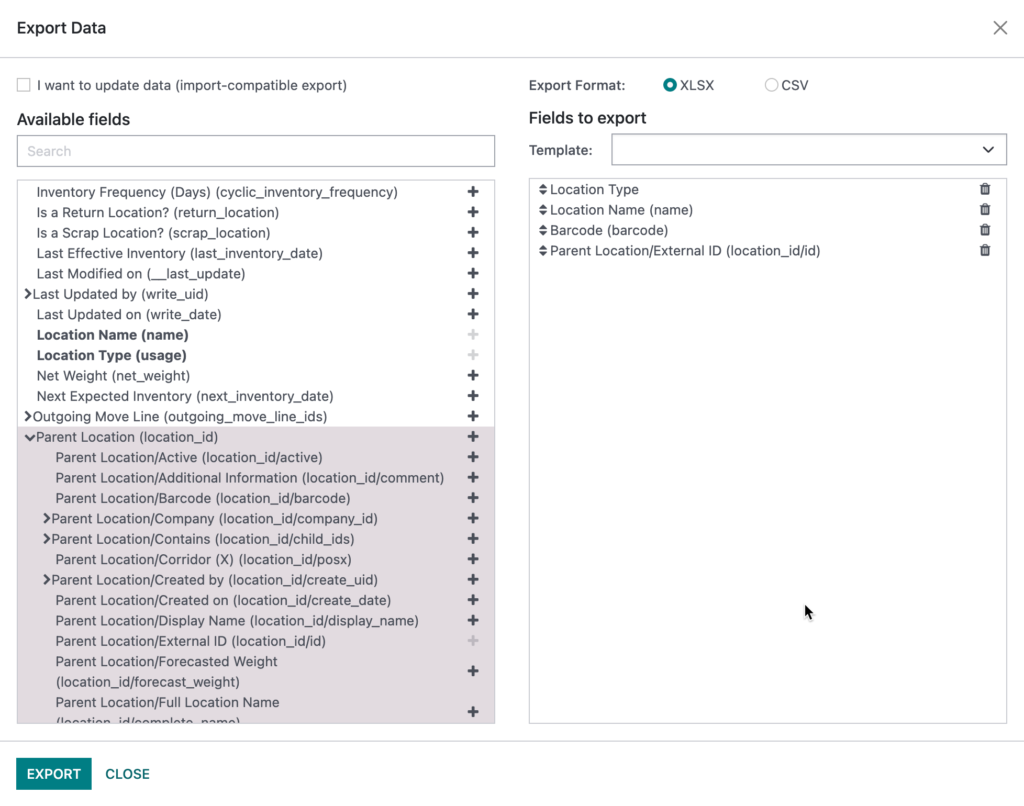

Then, Export the fields that you filled in the file with type .xlsx .

NOTE: Export Parent Location External ID, or ID field, to assign the correct parent location during import.

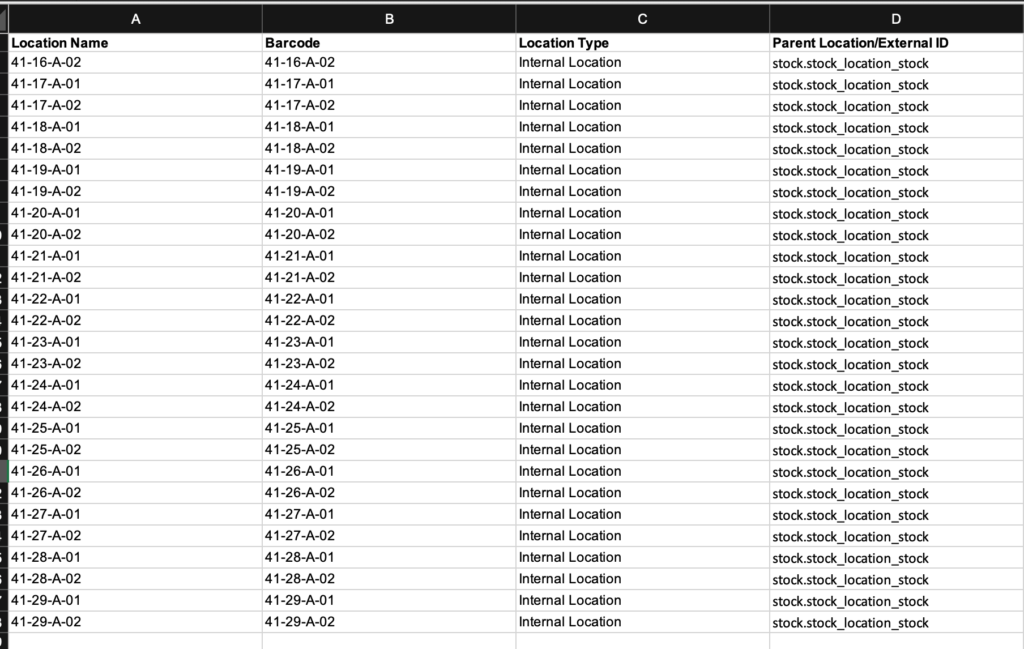

After that, paste the location names in your template.

Here is an example of an import file

NOTE: If you want to rename a location, export the external IDs and use them in your import file.

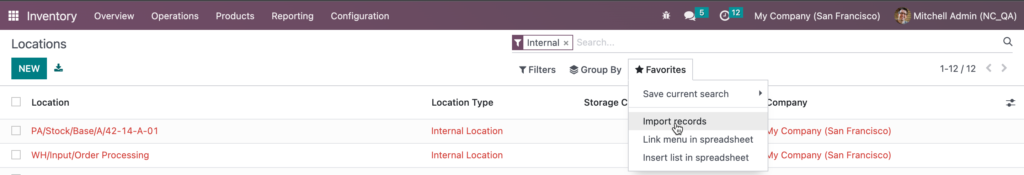

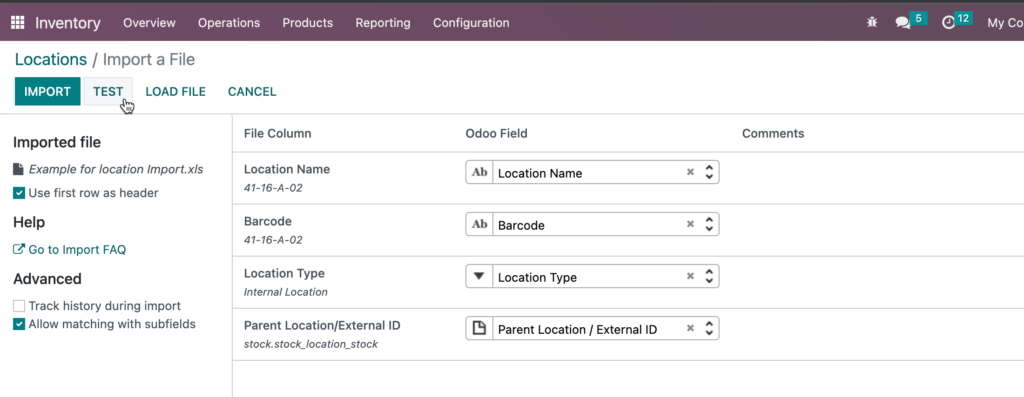

To import the file, open the Locations menu and click on Favorites ‣ Import records.

The columns from the file are mapped with Odoo columns automatically. If they were not mapped, you can map them manually by searching the list for the corresponding fields.

Click TEST to make sure that your data in the file is valid and that the columns are mapped correctly. If the test is successful, then click Import to upload your locations.

That is it. Now we have our warehouse map uploaded into Odoo, and we can define optimal routing.

Define an optimal routing strategy

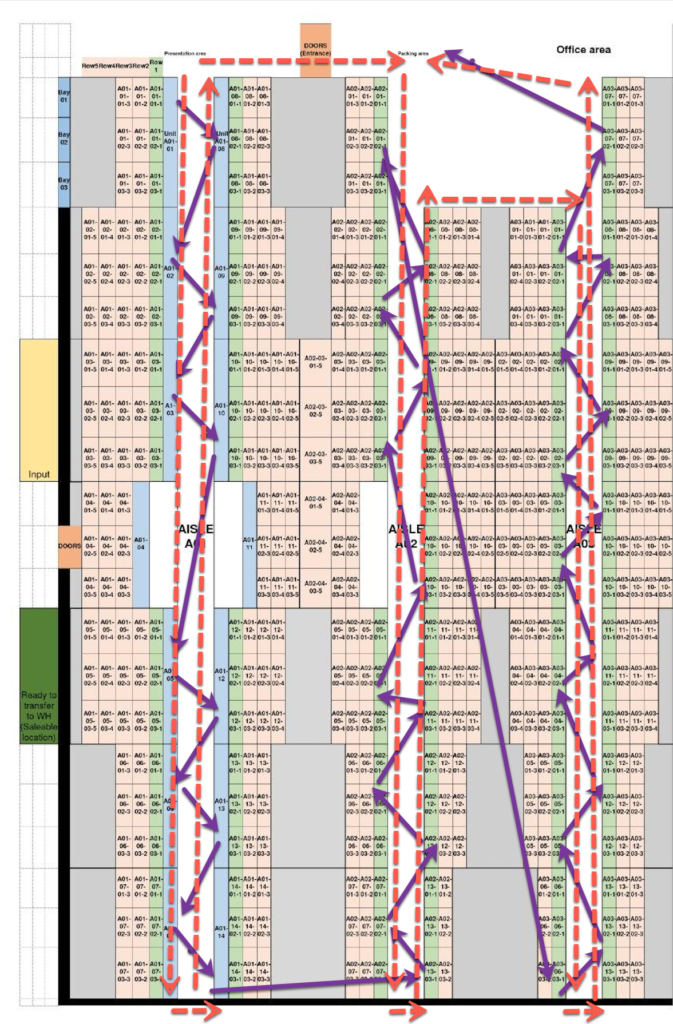

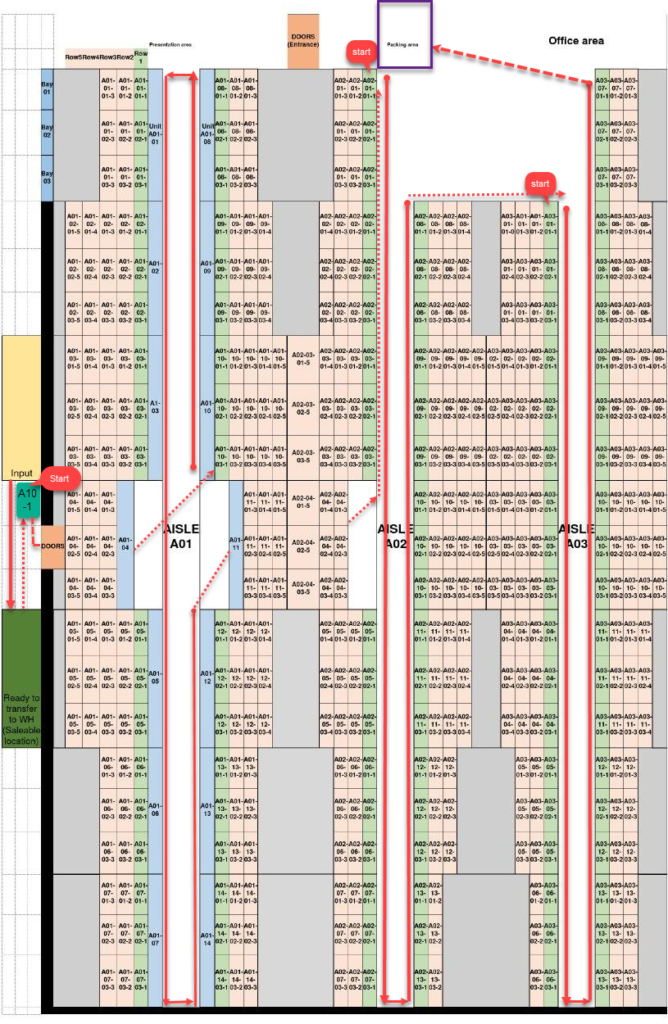

Let’s define an optimal routing strategy for warehouse workers to minimize walking.

A routing strategy is a plan that determines the route to pick up all the items. The goal of the routing strategy is to minimize the travel distance, thus minimize travel time.

Ask several users to take barcode scanners and go around your racks in the way they are sure is optimal. Open a text document or a spreadsheet and scan a barcode of each location on the way. Using the spreadsheet, draw your schematic routes of each user. Analyze and compare the results to define the optimal route.

If you have high-level locations, you can divide your workers and ask one group to go through the rows and scan the locations they can reach. Then have the other group use a forklift or a ladder to access to the high shelves.

Useful link: How to upload your picking route to Odoo

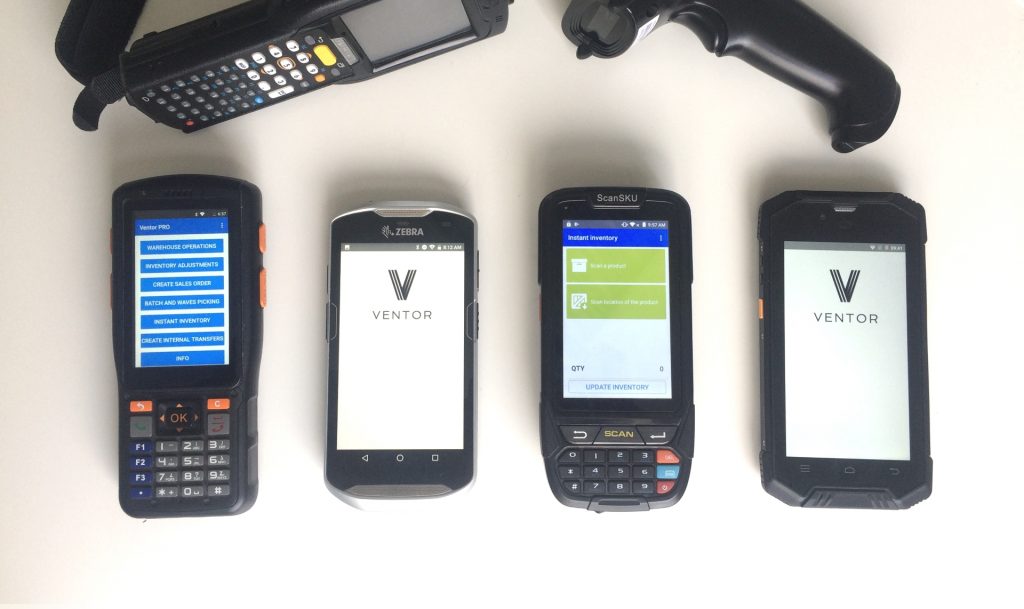

After that, all you need to do is to give your pickers barcode scanners or handhelds with the installed Odoo barcode scanning app (e.g., Ventor PRO) and have them start picking your orders effectively.

Remember, for even more effective picking, you may consider implementation of Batch or Cluster picking methods in your warehouse.

Batch picking in Odoo – Odoo Batch picking + walking minimization. Picking optimization in Odoo using a barcode scanner.

Cluster picking in Odoo – Picking in an optimal route + sorting items per order. Cluster picking in Odoo. Ventor

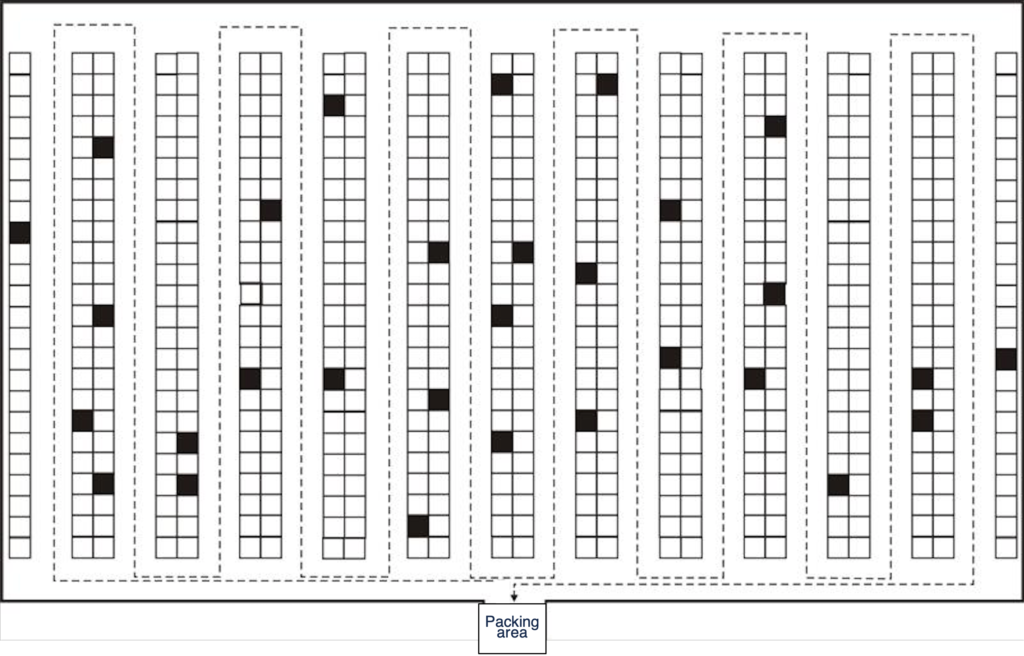

ABC analysis

To minimize picking time, you can apply ABC analysis and arrange products in the warehouse based on their ABC classifications. Place high-demand products (A) in easily accessible areas near the packing zone to minimize travel time. Moderate-demand products (B) should be placed in secondary storage areas, and low-demand products (C) can be placed in more remote or high storage areas.

We will overview the ABC analysis and show you how to implement it in Odoo in a separate article. Subscribe in order not to miss updates.

Results

Based on the prepared warehouse maps, we have optimized workflow and operational efficiency in the warehouse for our customers, with the following results:

- Savings of up to 50% in time spent on the picking operation

- 20% decreases in delivery lead times

- Expenses reduction of personnel involved in the picking operations

Want to optimize your Odoo Inventory?

Recommended articles:

- Receiving goods in Odoo via a barcode scanner: Receive, putaway, manage lots, serial numbers, packages

- How to build picking routes in your warehouse for walking minimization

- Ways to Overcome Logistic Problems with Odoo

- Print product labels from Odoo directly to a printer with 1 click via Odoo Direct Print PRO

I'm a responsible, enthusiastic and goal-oriented team player Business Analyst with 3+ years of experience in web projects for companies in Europe and the USA. I have been involved in B2B and B2C projects.

I'm open to new knowledge and experience in business analysis and project management.

2 Comments

Jaime

Excited about the ABC analysis article!

Vasily Puntus

Thank you for your interest. We are going to write about it next year.

We did ABC XYZ analysis for a few of our customers. If you are interested, we can discuss this service. Please drop us an email at [email protected]