Odoo for Equipment Manufacturing

Optimize your equipment manufacturing with Odoo ERP — from production planning and BOM control to inventory management and on-time delivery.

Book a free consultationEquipment Manufacturing Challenges Holding Back Your Growth:

The equipment manufacturing industry faces a wide range of operational challenges — from production bottlenecks and disconnected systems to manual data entry, inventory issues, and BOM (Bill of Materials) control. These obstacles hinder efficiency, increase costs, and compromise customer satisfaction. Without the right systems in place, such problems can escalate quickly. Below are some of the most common issues that equipment manufacturers encounter:

🔄 Inefficient Coordination

Key departments lack integration and rely on outdated tools, leading to poor coordination and limited visibility across the manufacturing process.

⚙️ Limited Process Automation

Manual scheduling, tracking, and control reduce production efficiency. Many of these outdated systems lack digital tools, machine integration, or smart automation wizards.

🔢 Managing Lot & Serial Numbers During Assembly

Lot and serial tracking is key for warranty, recall, and compliance. Lack of tools delays root-cause analysis and quality checks.

📦 Poor Inventory Visibility

Disconnected systems make it hard to track material flow, causing gaps in inventory visibility during receiving, storage, and picking.

🧪 Quality Control and Traceability

Poor traceability limits defect detection and root-cause analysis, putting compliance and product standards at risk.

💰 Inaccurate Costing and Quoting

Without cost breakdowns by labor, materials, and overhead, quotes become inaccurate, leading to lost sales or lower margins.

🌐 Complex Supply Chain Management

Lack of supply chain visibility and coordination causes delays, part shortages, and inability to react to demand changes.

🛡️ Spare Parts & Warranty Management

Missing links between BOMs and spare parts slow replacements, increase service costs, and frustrate customers.

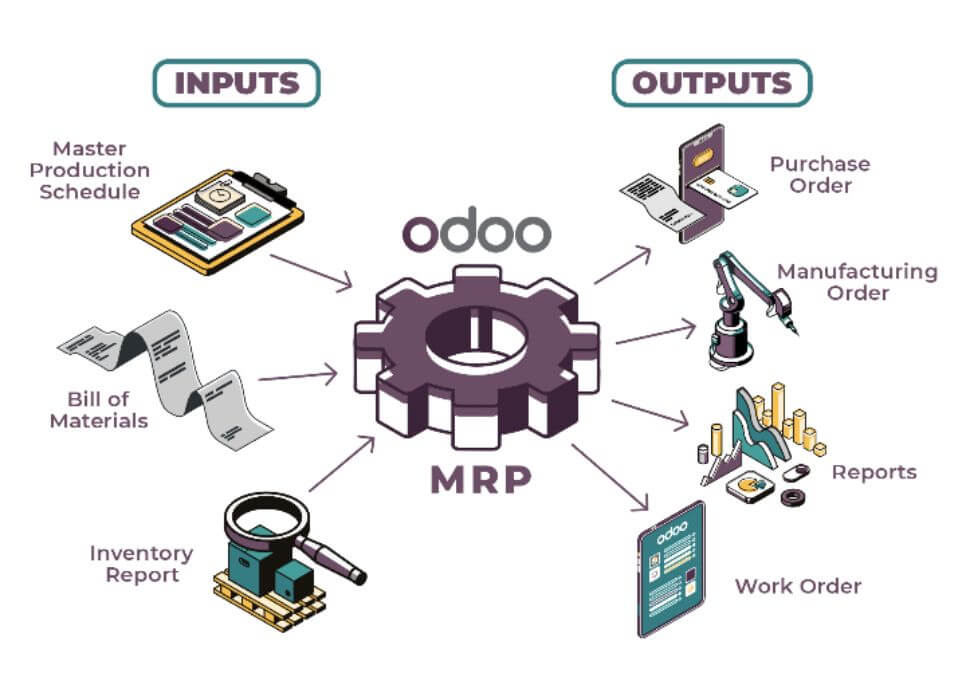

How Odoo Implemented by VentorTech Helps the Equipment Manufacturing Industry

Connected Production & Planning

We connect production, sales, and procurement in Odoo — so that planning, quality control, and delivery timelines are always aligned. This ensures every order is built right and delivered on time.

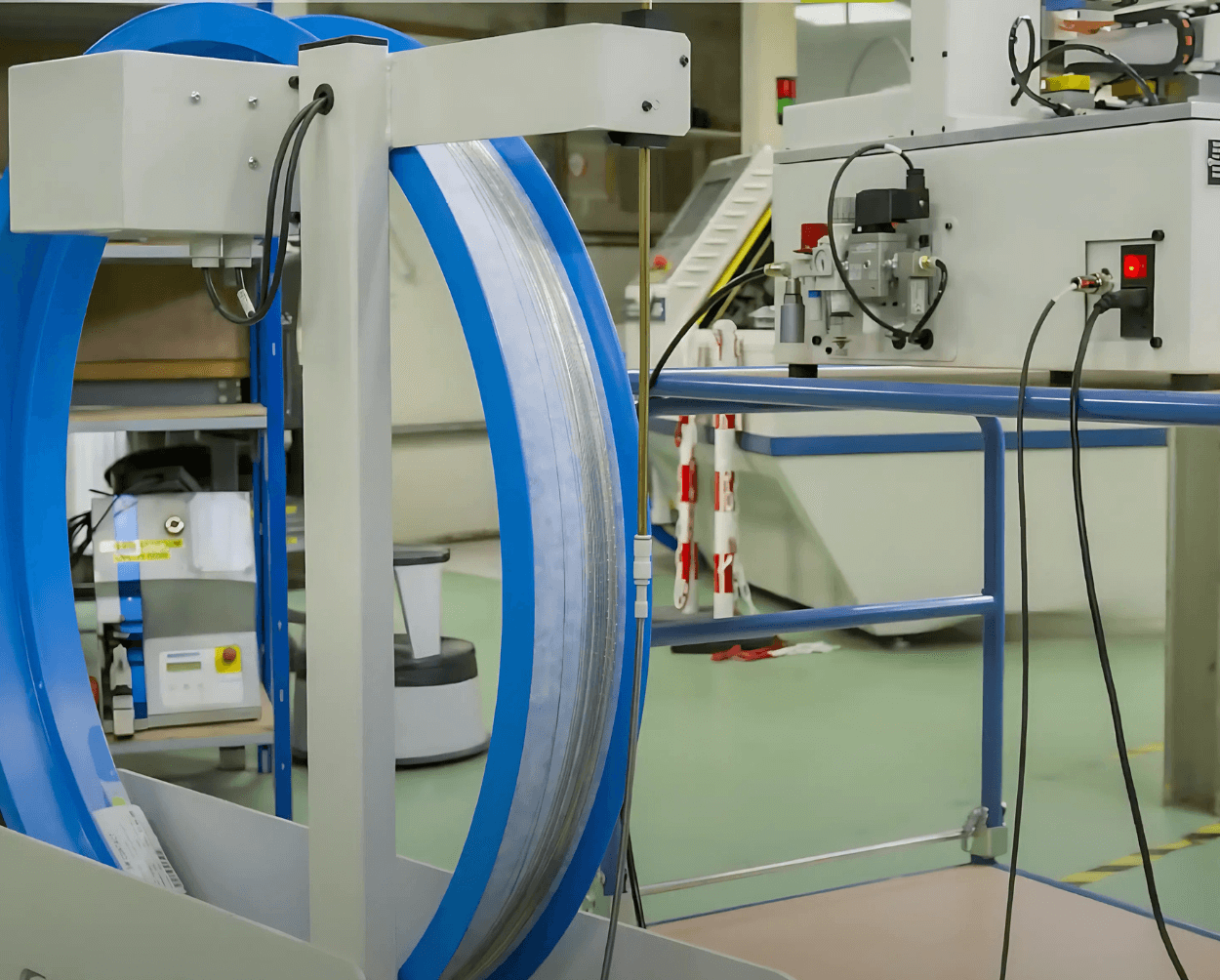

Practical Warehouse and Logistics Improvements

We configure real-life warehouse flows in Odoo — from reception and fast-pick zones to labeling and route optimization. Our solutions support efficient picking, packing, and shipment planning to help your logistics stay predictable and responsive.

Purchasing & Supplier Management

Odoo brings structure to procurement: automated reordering, vendor evaluation by performance, and centralized price lists. This reduces lead time issues, avoids warehouse overflow, and helps prevent production delays.

Accounting That Matches Equipment Manufacturing Reality

Odoo accounting helps manufacturers sync finance with operations. We set up payment integrations, simplify invoicing and tax workflows, and support bank reconciliation. For global teams, we also handle customs declarations and currency conversion to keep financials accurate in real time.

Marketplace and eCommerce Integration

We configure Odoo to sync product data across Amazon, eBay, Etsy, Shopify, and other platforms. Product catalogs, inventory, and pricing stay consistent, which reduces errors and saves time across sales channels.

Full Lifecycle Support: Repairs, Warranty, and Scraps

Tracking and servicing equipment after it ships is just as important as building it. We configure Odoo to manage serial numbers, warranty periods, repairs, and scrap procedures. When a customer calls with an issue, your team will have full visibility into the unit’s history — what was sold, when, and with which components.

Looking to Streamline Equipment Manufacturing with Odoo ERP? Schedule a Free Consultation and See How We Can Tailor This System to Your Production Needs.

Book a free consultation

Why Clients Choose VentorTech

- 🔹 Deep Expertise in Odoo ERP Implementation: 10+ years of Odoo ERP experience with manufacturers, wholesalers, and service companies.

- 🔹 A Full In-House Team of Professionals: A strong team of developers, analysts, and support engineers — including team members with hands-on experience in equipment manufacturing projects.

- 🔹 Proven Manufacturing Cases With Measurable Results: See how Odoo helps equipment manufacturers reduce errors, speed up delivery, and scale operations.

- 🔹 Custom-Built Apps and Connectors: We are the best European developers of the Odoo apps and connectors for the equipment industry (e.g., our barcode scanning app for warehouses.

- 🔹 End-to-End Support: From business analysis to post-launch growth, we always cover the project lifecycle’s crucial phases.

- 🔹 Client-First Approach: Our client-centric approach ensures transparent communications, tailored solutions, and long-term partnerships.

Success Stories with Odoo Implementation in Equipment Manufacturing

Led Ner SAS

Electric Lighting Equipment Manufacturing.

Problem: The company faced a major bottleneck with product knowledge confined to just two individuals. Daily communication gaps between departments also slowed progress.

Solution: We implemented a custom Odoo solution that included a smart product configurator and real-time sales order statuses.

Result: As a result, they reduced errors, improved visibility, and scaled operations.

Learn More

SM Contact Tech

Electronics Equipment Manufacturing

Problem: The company struggled with poor coordination between sales and manufacturing, leading to delayed deliveries and stalled growth.

Solution: We implemented Odoo ERP to automate and link these critical processes.

Result: As a result, sales orders are tracked accurately, manufacturing is prioritized efficiently, and the sales team can focus more on closing deals rather than handling routine tasks.

Learn More

Frige B.V.

Consulting and Selling Electrical materials

Problem: A huge product catalog and increasing order volumes made it challenging to deliver orders on time and keep the product catalog continually updated.

Solution: We automated product updates via 2ba.nl and enabled barcode-based order picking with our Ventor app.

Result: The customer eliminated manual product updates in Odoo. The fully automated order delivery process ensures timely shipments and strict inventory control.

Learn MoreOur Odoo Implementation Process

1️⃣ Equipment Manufacturing Process Analysis

We start with a detailed analysis of your current processes, bottlenecks, and inefficiencies — to define where Odoo will bring the most value.

2️⃣ Solution Architecture Design

We design a tailored Odoo ERP structure with the right modules, integrations, and scalability to support your goals.

3️⃣ System Implementation and Team Training

We configure and deploy your system, and train your team with step-by-step onboarding and real examples.

4️⃣ Ongoing Support and System Scaling

After launch, we provide SLA-based support, upgrades, documentation, and sessions — to keep Odoo aligned with your growth.

Ready to Optimize Your Equipment Manufacturing with Odoo ERP?

Talk to us nowWe Support Integrations with:

eCommerce Platforms

Odoo EDI

Suppliers and Dealers

Zebra Technologies

and other similar hardwareDelivery Services

Testimonials

We owe thanks to VentorTech for their excellent support throughout our digital transformation with Odoo.

🇫🇷 France, Quincy-Voisins

Evgeniy Belosludtsev, Head of Digital transformation

SM CONTACTIt was a pleasure to work with all of you. Thanks for all the effort you put into the LEDNER project.

I won’t hesitate to recommend you for Odoo projects if ever I meet someone looking for an integrator.

🇫🇷 France, Carnoux en Provence

Robert Koppanyi, IT Manager

LED NERWMS based on Odoo has been a game-changer for us. It has dramatically increased our efficiency and made order picking and processing much easier. The system is very user-friendly, with a straightforward UI that our team loves. We are continuously improving it and our processes to get the most out of it and keep enhancing our operations.

🇺🇸 USA, Massachusetts, Billerica

John Papazian, Vice President

TH Electronics IncThe module I purchased was version 1.3 I had some changes, they did it, I had some inquiries, they did it. I had some bugs – they did it. All in due time, with good understanding. Such a nice working module!

🇩🇰 Denmark, Zealand, Naestved

Theis Dræberg, CEO

D-S Sikkerhedsudstyr A/SFAQ

-

⏳ How long does it take to implement Odoo ERP for an equipment manufacturing company?

As with other industries and domains, the implementation timeline depends on several factors: company size, project scope (including how much customization is needed), manufacturing complexity, and the level of automation. A project with minimal customization typically takes around 3–8 months.

-

📊 Can I track the real-time status of production orders and work centers?

Yes. Odoo provides live dashboards and work center control panels, so production managers can track progress, identify delays, and optimize operations in real-time—all while supporting a faster order-to-production process through centralized production management.

-

🛠️ Can Odoo manage engineer-to-order (ETO) or make-to-order (MTO) processes?

Yes, Odoo supports both ETO and MTO workflows. You can create custom BOMs, track designs, and link sales orders to production, ensuring accurate builds and delivery timelines.

-

✅ What kind of quality checks can be built into the manufacturing process?

With Odoo quality control automation, you can define quality control points at different stages—from incoming raw materials to final inspection—ensuring compliance with industry standards and reducing defects.

-

🔢 Does Odoo support serial number and lot tracking for equipment?

Yes, Odoo offers full traceability with serial and lot tracking, helping you monitor components, ensure quality control, and comply with regulatory standards.

Discover How Equipment Manufacturing Automation with Odoo Can Boost Your Efficiency!

Get a free consultation today or Call us at:

🇺🇸 +1 305 404 28 43

🇪🇺 +48 732 225 396