| Summary: VentorTech specializes in Odoo implementation for manufacturing industries — including equipment manufacturing, furniture & home goods, and packaging. In this article, discover how ERP systems like Odoo drive digital transformation by optimizing warehouse automation, improving customization and production planning, enhancing environmental compliance, and ultimately reducing operational costs across manufacturing operations. |

Trends in Industrial Digitalization

Modern technologies have become an integral part of almost every aspect of human activity, including digital transformation projects in manufacturing. They simplify routine work, speed up the analysis of large amounts of data, increase process efficiencies, and open new horizons.

Digitalization is the driving force that promotes business advancement and visibility. The main benefits of using smart manufacturing technologies include:

- Saving time and increasing productivity

- Reaching a new level of customer service

- Optimizing internal and external communications

Industrial digitalization involves using multiple technologies, such as artificial intelligence (AI), big data, cloud computing, robotics, and more, in order to improve product quality and make manufacturing more efficient, flexible, and reliable. For the digitalization to meet expectations, it is important to properly understand its scope: it is not just the automation of some repetitive processes, but a complex transformation of the entire manufacturing system, which consists of many aspects.

When talking about primary industrial digitalization trends, we cannot fail to mention Industry 4.0 (Fourth Industrial Revolution), as we are now involved in this digital revolution that is happening right before our eyes. Industry 4.0 is a concept that implies a rapidly growing automation of traditional and production practices with the use of the latest technologies. It involves the use of the Internet of Things (IoT), cyber-physical systems, AI, and cloud computing. Industry 4.0 in manufacturing is characterized by the integration of the digital, physical, and biological worlds.

Other important trends in industrial digitalization include the introduction of robots and automated systems for routine operations, high levels of cybersecurity, big data and analytics, and cloud technology.

In this article, we will elaborate on the transformation of manufacturing facilities through digitalization and talk about the importance of an ERP system for unified manufacturing management.

Equipment Manufacturing: Automation, IoT, ERP

The introduction of digital technology is having a positive impact on all aspects of manufacturing, including equipment. This allows manufacturers to effectively reduce costs, optimize production processes, and accelerate the launch of new products on the market. Some of the most common and effective areas of digital transformation include automation, the IoT, and switching to a cost-effective ERP solution.

Let’s take a closer look at these innovations in relation to manufacturing.

Why Manufacturing Automation Matters

The processes automation is a mandatory aspect of successfully functioning equipment manufacturing. Such automations increase productivity, reduce costs, improve labor safety, make production more flexible, and thus increasing the company’s competitiveness on the market. Equipment manufacturers that have already replaced manual labor with mechanized processes are able to produce increasingly relevant, specific products, have nearly eliminated production risks, and can quickly adapt to changes in demand.

Reducing Routine Tasks

Every manufacturing effort involves many routine processes. Automation of these processes results in a somewhat unexpected yet huge social value in saving resources and time for employees. Automating routine tasks improves a company’s working environment and allows employees to focus their energy on more strategic issues.

Improving Product Quality

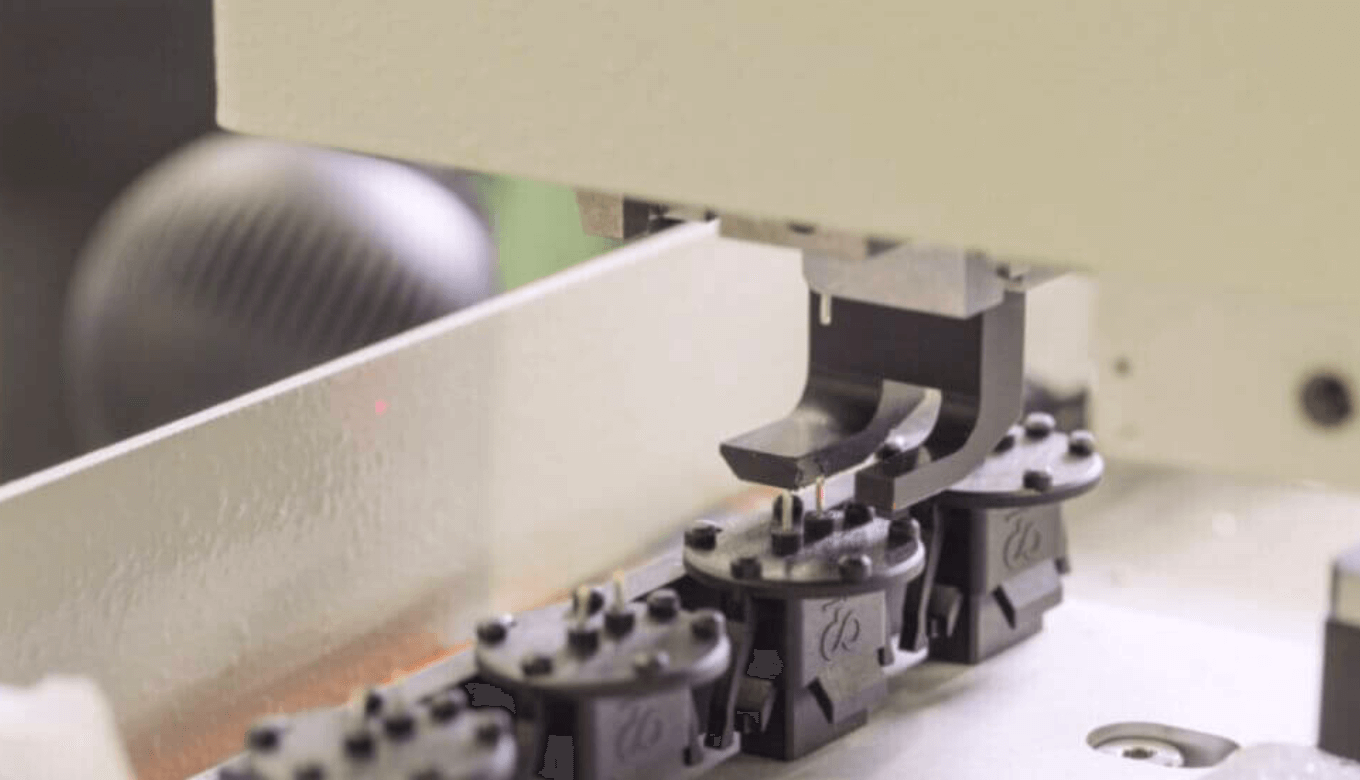

Automation helps to strengthen control over product compliance with standards. This results in lowering significant production risks along with fewer defects.

Accelerating Order Fulfillment

Automation and robotics in production greatly speed up processes since they eliminate human error. This area of automation also significantly increases productivity by making it possible to produce more products in any given amount of time.

IoT: What It Is and How It Improves Manufacturing

IoT in manufacturing is a concept in which devices, sensors, and equipment are networked to collect and analyze data and to exchange information. IoT-enabled sensors are actively used to monitor equipment performance, which then helps to quickly identify and correct problems.

IoT is facilitating the transition from traditional service to a more efficient and predictive one. Predictive maintenance manufacturing involves using sensors installed on equipment to collect and analyze data, predict potential breakdowns, and schedule maintenance work. This helps optimize maintenance costs and prevent unplanned downtime.

According to a survey among manufacturing companies, digital transformation of processes and IoT increases efficiency by 82% and customer satisfaction by 45%. Below, we have provided examples of a few areas of manufacturing that are particularly benefiting from IoT.

Inventory Management

IoT solutions enable the use of sensors to track product movements in the warehouse and real-time supply chain activities. Robotics in manufacturing opens up new opportunities, as autonomous robots can move products and pack orders without employee involvement. This allows workers to devote greater attention to more important tasks.

Human Resource Management

Sensors collect information from equipment, machines, and mobile devices, which helps manufacturers to accurately assess the quality of employee performance. All data is automatically updated in real time, allowing for a full view of the entire situation, which is critical for making informed decisions. In this way, IoT provides advanced monitoring capabilities and clearer transparency of employees’ work activities.

Product Quality Control

One popular way to track products on production lines is through machine vision using high-resolution cameras. The equipment is connected to a cloud-based platform, whileand video sensors and software help to effectively monitor product quality. In this case, IoT prevents low-quality products from reaching the customers, which and improves the company’s reputation in the market.

Importance of ERP Systems for Manufacturing

Modern manufacturing facilities cannot function properly and fulfill their processes without a reliable ERP (Enterprise Resource Planning) system. This system allows manufacturers to optimize and automate important processes, ensuring efficient planning and management of resources and production control. The value of an ERP system for production entails lies in many aspects, the main ones of which we will summarize below.

Unified Information Environment

Manufacturing ERP integration implies the creation of a single database containing all necessary information. This includes data on production processes, inventory, manufacturing resources, orders, and relationships with customers and suppliers. Effective integration allows for quick decision-making and real-time access to the most relevant information.

Interaction Between Departments

The ERP system ensures smooth interaction between all departments of an enterprise. Thus, employees of different departments have access to any information they are interested in and can perform their tasks faster with more efficiently.

Financial Accounting Opportunities

Modern ERP systems provide powerful functionality for working with finances. They integrate data from different sources and provide the operator with a single financial information source that is updated in real time. ERP systems also simplify financial documentation and automate accounting processes.

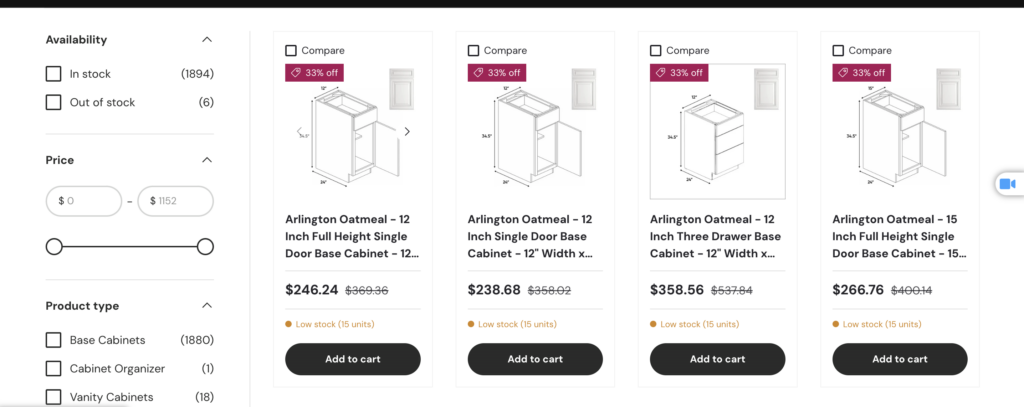

Furniture & Home Goods: Customization and Warehouse Control

The business of producing furniture and home goods is quite competitive today. Implementing digital technologies and constantly exploring new methods to keep customers’ interest increases a company’s competitiveness. The latest technologies are defining the future of the furniture industry and significantly enhancing customization in home goods production. The most popular tools in this area are augmented and virtual reality, automation, and the use of digital twins for simulating actual situations in order to make increasingly informed decisions.

Augmented and Virtual Reality (AR and VR)

Companies are using AR and VR to visualize furniture or home decor elements within a real interior. These technologies significantly improve customer experience and help optimize production processes.

Automation

Automation of furniture manufacturing is an important step in its digital transformation. This automation includes various manufacturing stages, from product design to assembly and packaging. For example, warehouse automation systems improve inventory control and make warehouse processes more transparent. Warehouse operations automation involves the introduction of robotic systems for the internal goods movement, sorting systems, and automated racking systems.

Digital Twins

Digital twin manufacturing is a copy of the enterprise in a virtual environment. This technology allows for getting additional percentages of increased output or reduced wear and tear, and energy consumption without replacing expensive equipment. The digital twin of future manufacturing allows for stimulating different production scenarios, identifying weaknesses, and optimizing operations sequencing. Given these increased planning capacities, furniture and home goods manufacturers improve product quality, reduce production time, and increase production efficiency.

The Influence of Digital Transformation on Packaging Manufacturing Processes

The packaging manufacturing industry is growing, and its importance to the retail sector is only increasing. Digitalization is fundamentally changing packaging production operations, offering huge advantages in terms of efficiency, consumer engagement, and sustainability. The digitalization of packaging manufacturing is strategically important and is entirely changing the landscape of this industry.

Reducing Costs and Increasing Efficiency

AI and IoT help to optimize packaging production processes, while automated systems perform routine tasks at lightning speed, reduce reliance on human labor, and minimize errors. Specialized equipment maintenance tools can anticipate breakdowns before they occur, allowing companies to take action in time and prevent costly downtime.

Improved Raw Material Flow and Smart Inventory

The digital transformation of packaging production, specifically the introduction of an ERP system, such as Odoo ERP, significantly enhances warehouse coordination and material control. The manufacturer can track return and scrap flows in real time and manage different materials across multiple warehouses with accurate categorization.

Supporting Environmental Initiatives

Digitalization enables the use of sustainable materials in packaging manufacturing. Digital platforms promote the principles of the circular economy. This involves tracking and managing the packaging lifecycle, promoting recycling and reuse.

The use of sustainable materials in packaging helps reduce the use of natural resources and improves the company’s reputation. Recent studies have shown that 51% of customers check packaging for sustainability before purchasing, and 66% of customers avoid a product or brand for environmental reasons.

Using eco-friendly materials in packaging manufacturing brings many benefits to manufacturing, including:

- cost reduction

- resource savings

- waste reduction

- improved company image

- reduced emissions

- legislation compliance

- improved working conditions

In addition, digital transformation enables efficient package production planning and execution, customer sales performance tracking, managing real-time logistics in packaging distribution, and reliable support for international production and distribution. So, if your packaging production system needs any of these features, we encourage you to learn more about the benefits of Odoo ERP for packaging production right now!

Unified ERP Approach for Complex Manufacturing

Digital transformation of manufacturing is not possible without the implementation of an ERP system, as it allows for automating all business processes, increasing efficiency, and improving resource management. Below, we will explain the benefits of ERP for complex manufacturing processes.

Procurement Automation

The procurement module is one of the most valuable ERP sections, as it helps to simplify and automate the complex supply cycle of raw materials and other components. ERP solutions allow manufacturers to accurately forecast the required procurement volumes and select the best supplier offers. In addition, manufacturing facilities that have implemented the ERP system automatically create purchase orders and control budgets and risks.

Logistics Optimization

Modern ERP systems include logistics modules and WMS subsystems, which open up a wide range of opportunities for supply chain management. A huge advantage of ERP for logistics management is that it provides full visibility and control over all stages of the supply chain. This allows manufacturers to increase warehouse throughput, improve inventory management, and reduce overall logistics costs. What is more, an ERP system involves the use of AI in manufacturing logistics, and it effectively optimizes the load on the fleet, builds efficient schedules, and establishes transport routes.

Unified Approach

This approach involves using an integrated system to manage all aspects of manufacturing, from the procurement of raw materials to the delivery of finished goods. The ERP system integrates all departments and functions into a single information environment and ensures data consistency. The benefits of a unified ERP approach for complex manufacturing include:

- improved decision-making

- reduced costs

- iincreased efficiency

- enhanced product quality

- upgraded internal communications

- heightened competitiveness

Unlock Smarter Manufacturing Operations with Odoo ERP!

Conclusion

Digital transformation and the use of advanced manufacturing software solutions are essential for the successful development and operation of a modern manufacturing environment. This allows for improved customer interactions, faster decisions, cost reductions, and multiple process automations.

IoT, ERP systems, automation, AI-based tools, and many other technologies make manufacturing more flexible and innovative, and allow it to quickly adapt to ever-changing customer needs. Implementing warehouse control solutions optimizes warehouse operations, reduces costs, provides accurate inventory control, and delivers detailed analytics and reporting on warehouse operations.

With your increased understanding, you will want to think about digital transformation for your manufacturing business right now to make all your processes automated and more efficient!

Recommended articles:

- From Manual Operations to a Smart Warehouse: How WMS Handles Growth Challenges, Reduces Costs, and Enhances Your Logistics Efficiency

- Odoo inventory optimization for a Baltics packaging supplies retailer, PaperSeal

- How Odoo implementation automated 10 months of manual work and saved over €22K annually

- Key Performance Indicators (KPIs) and their Role in Successful ERP Implementation

- Odoo Implementation Steps

- The True Cost of Odoo ERP: Pricing and Ownership Insights

----------------------------------------------------------------------

Education: Bachelor's degree.

----------------------------------------------------------------------

Experience:

Marketing manager

VentorTech

----------------------------------------------------------------------

Current position: Marketing manager VentorTech

----------------------------------------------------------------------

B2B Marketing

Google Tag Manager and GA

0 Comments