Company name: TH Electronics Inc

Location: United States, Massachusetts

Industry: Repair, Electronics, Medical Equipment

Company size: 10–50 employees

VentorTech Solutions: Odoo Implementation and Customization, Odoo Direct Print / Ventor, Ventor PRO, AI Order processing, ZPL Label Designer

Goal: Have an ERP system that would cover the full repair process from reception to delivery without limits on storage data and orders.

About the Customer

TH Electronics is a leading U.S. provider with a 30-year history in the areas of equipment repair, remanufacturing, and reengineering solutions for the medical electronics industry.

“We are an industrial repair company, servicing equipment used in hospitals around the world”. – John Papazian, TH Electronics Vice President.

Challenges

The company’s main challenge was its legacy ERP system, which created several obstacles to efficient work and continued growth:

Scalability Issues: As order number increased daily, the old system could not handle the company’s growing work volume.

Frequent System Crashes and Performance Issues: Systemic bottlenecks happened too often due to limited memory and lack of scalability.

High Maintenance Costs: Supporting and upgrading the old system was quite expensive.

Lack of Analytics: Specific reports were needed to make better business decisions.

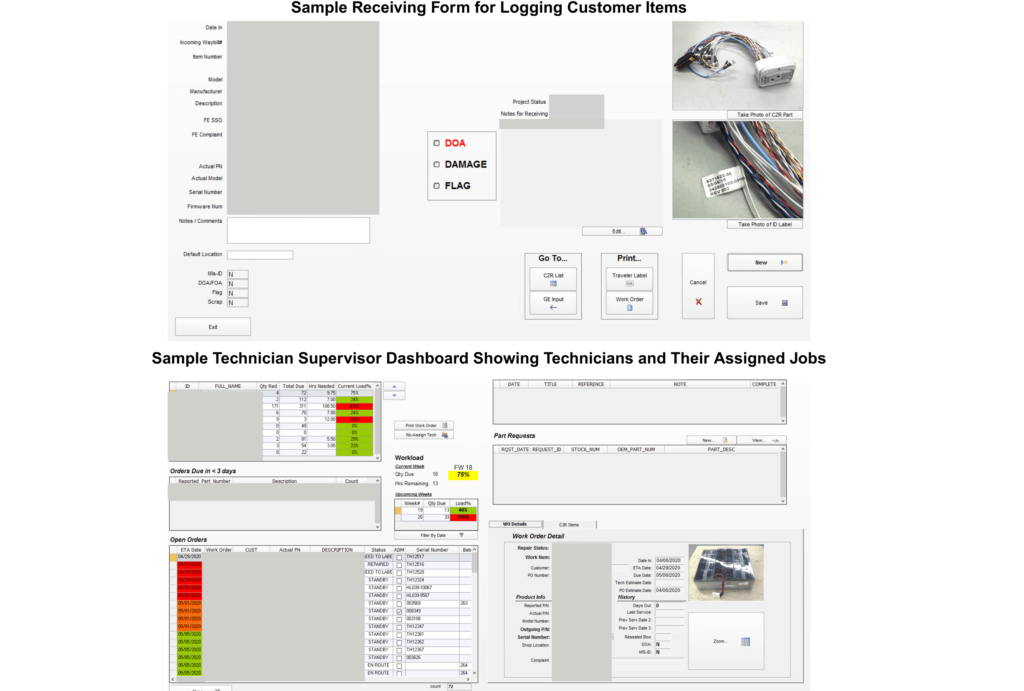

Complex Onboarding Processes: The system, although functional for basic necessary tasks, had not been built for long-term forecasted growth and success; therefore the UX needed to be updated, making its user navigation and other functionalities more convenient for daily operations.

Accounting Limitations: The legacy ERP had to be used in connection with QuickBooks.

Lack of Automation:

- The system stored large amounts of data but lacked proper validation and workflow automation.

- Users needed to remember the sequence of actions and what data needed to be added, which increased the risk of errors.

- Inventory adjustments could only be done manually, which consumed valuable time.

- Shipping labels for internal and external needs had to be printed manually.

Solution

The client chose migrating to Odoo ERP, as the program’s open-source, easy-to-customize, and modular structure allows for seamless scalability.

Given the company’s processes and unique business needs, we knew that simply replacing the old system with default Odoo modules would not work. Customization was essential.

“Although I have purchased an Odoo license, I have not been able to successfully implement a software solution due to the complexities of our business model. My need for direct printing led me to research the topic, which is how I discovered VentorTech and the PrintNode app. After that, I watched VentorTech’s tutorials on YouTube and learned about the Ventor PRO mobile app. Altogether, this research showed me more about their expertise in creating customized solutions for a company like ours. We then decided that we needed to partner with VentorTech.”. – John Papazian, TH Electronics Vice President.

We started from the Odoo discovery phase to understand the client’s business workflows and identified the most important processes for automation. Critical areas included:

- Reception process and payment of repair orders

- Repair process

- Inventory

- Reporting and analytics

Make the switch from manual work to business process automation.

We outlined each process, figured out gaps in Odoo, and created mockups with diagrams of each flow for future customization.

The following Odoo apps were selected for this project: Sales, Manufacturing (for dealing with repair issues), Quality Control, Inventory, Purchase, Accounting.

Automated Workflow Order Creation and Payment Adjustments

“Yes, this is a good point, order entry is now automated, which is a big improvement”. – John Papazian, TH Electronics Vice President.

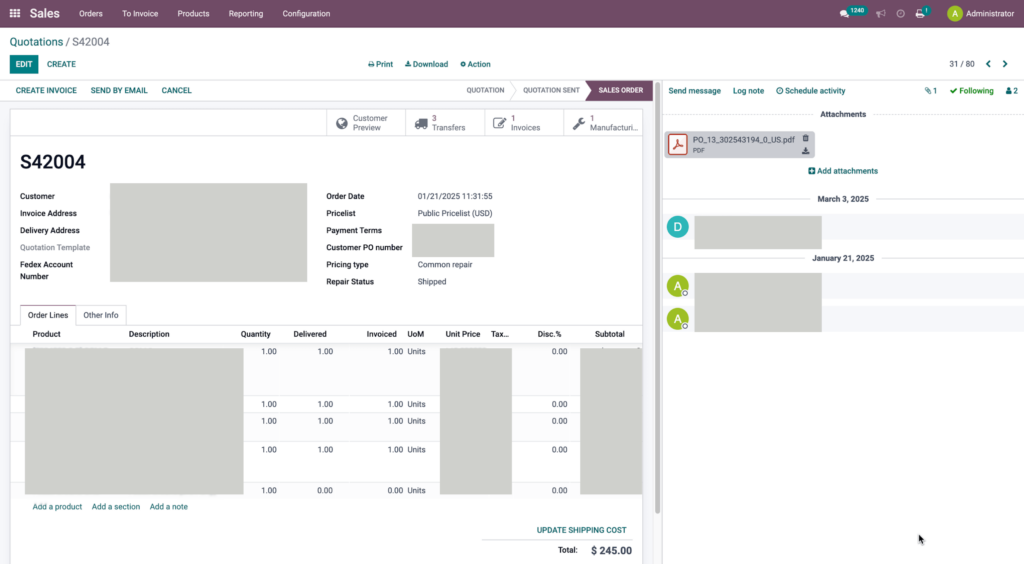

The client receives customer orders usually via email with a PDF file attached. Manually entering all the order details into the system had been time-consuming and entailed errors. To streamline this process, we developed an automated import feature.

This automation allows users to directly import PDF orders into Odoo, converting them into sales orders while capturing essential details (such as customer name, contact details, SKUs, and product descriptions). After that, a sale order will trigger actions in the ERP system directly to create repair orders (with products information and a future possibility to enter serial numbers with expected failures), incoming deliveries (with calculated planned delivery dates, products, and clients details), outgoing transfer (with a planned shipping date, products, and clients details), thus also preparing the full chain of documents for users.

This solution significantly reduces manual data entry, which saves time and minimizes errors. Additionally, the automated process notifies the user if some information, such as a product name, price, or address, is missing from the PDF, helping to update related details before repair parts arrive.

If customers want to make changes to the order or cancel it, the system recognizes the existing order and updates it instead of creating duplicates. It also notifies the responsible user, ensuring seamless order management.

Note, later, we enhanced this functionality and improved order processing using AI. You can read more about this here.

Repair Workflow Automation

- Automated Repair Order Creation & Technician Assignment

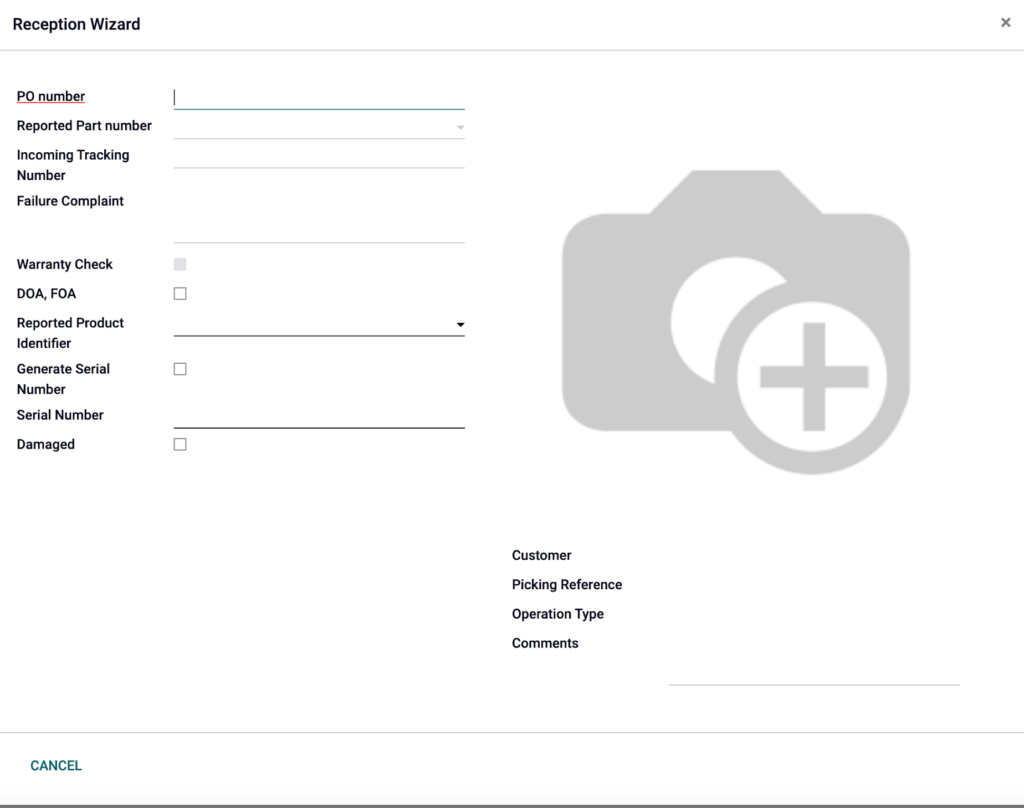

The system is able to automatically generate repair orders in Odoo and assign them to technicians based on their skills and workload, ensuring efficient task distribution. - Simplified Reception Process with the Reception Wizard

To speed up repair parts reception, we created the Reception Wizard. This tool allows users to scan barcodes from the order box to instantly get product details, expected failures, and related documents. Manual data entry is still possible if needed. This improvement has significantly streamlined the process of receiving and moving parts to the repair location.

- Automated Component Selection for Repairs

Since medical equipment is highly complex, with some products containing over 1,000 components, selecting repair parts manually proved to be inefficient. We enabled Odoo to analyze the product history and its associated repair history in order to offer necessary components automatically. This process now helps technicians work faster and more efficiently. - Advanced Order Tracking

We introduced additional order statuses, allowing responsible users to track each order’s progress in real time—whether it has been received, is in transit, or is currently under repair.

- Warranty Tracking

Warranty details are now in the Odoo sales order, making it easy to check and manage. - Quality Control Management

The system now uses Odoo’s built-in Quality Control features to ensure all repairs meet industry standards. - Dealing with Incorrect Parts

Sometimes, customers send the wrong parts for repair, meaning that order details do not match the actual item received. To handle this, we created a dedicated process for receiving, storing, and repairing these items, in case the customer does not request a return. - Scrap and Return Process

Some customers insist that non-repairable products be returned. To manage this, we implemented a scrap and return workflow:

– The technician submits a scrap request.

– Senior technician reviews and validates it.

– If confirmed, the system automatically generates a shipping transfer for the customer.

Inventory Management

- Warehouse Mapping for Optimized Routes

We created a warehouse map to build the most efficient routes for picking components and managing outgoing shipments. - Flexible Shipment Process

The delivery process now includes two shipping options:

- 1-step delivery for large products.

- 2-step delivery for smaller items, allowing them to be consolidated into a single pallet for shipment.

- 1-step delivery for large products.

Additionally, we upgraded the Odoo FedEx connector, enabling users to select third-party payment as a general payment method for specific customers.

“Actually, there’s more efficiency in our warehouse shipping/receiving and with better accuracy, thanks to FedEx integration”. – John Papazian, TH Electronics Vice President.

- Automated Label Printing

With the help of Odoo Direct Print App and ZPL Label Designer, we enabled automatic label printing with custom labels and predefined printing scenarios. - Warehouse Process Optimization with Ventor PRO

Using Ventor PRO, we enhanced several warehouse operations, such as: reception, Inventory adjustments, internal movements, and more.

Boost your Odoo inventory efficiency today!

Reporting and Analytics

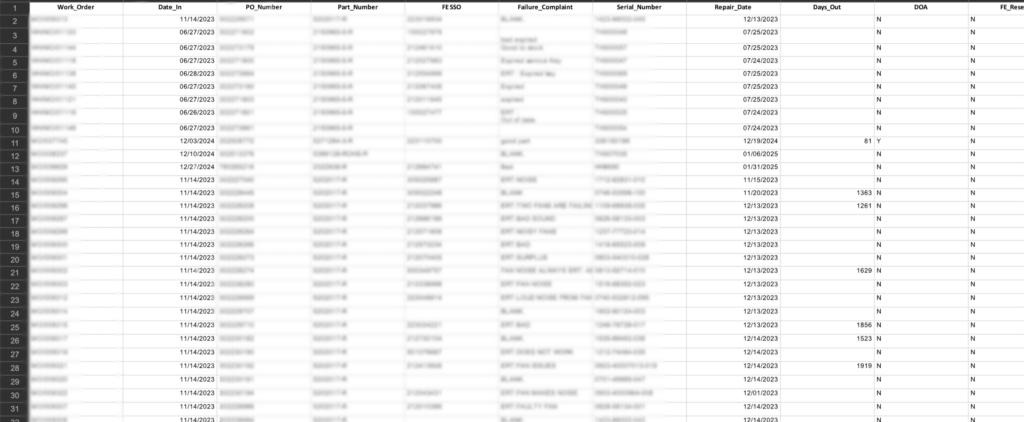

Along with standard Odoo reports like sales reports, inventory, and accounting, we developed specific reports crucial for this type of business: profitability analysis, employee performance analysis, and product repair statistics.

Repair Details Report in Odoo

Automated Workflow Triggers

To enhance coordination between departments and technicians, we utilized Odoo’s Activities Tool. TH Electronics has a 2,000 sq. meter production space in the US and clear task management was essential to improve efficiency while preventing miscommunication.

We implemented a task system allowing issues to be resolved more effectively by enabling the following:

- Automatic creation of a chain of activities for users and user groups

- Automatic start of processes according to the action scheduler

- The ability to assign activity to a group of users at once.

All of these features automatically and instantly streamlines processes and promptly resolves problems or other issues.

The Odoo project’s staff, lead time, and cost

Team:

- 0.25 PM for all the time.

- 1 full time BA for all the time.

- 1 full time developer and 0.5 developer for all the time.

- 0.5 QA for all the time.

Lead time:

12 months before going live + ongoing support and improvements after going live.

Project size:

MMC project. More than 3,000 hours before going live.

ROI:

Project cost was returned within half a year after going live.

Results

Moving from a legacy ERP system to Odoo led to the automation of most of the business’s manual processes. This resulted in:

Business growth: In just 15 months, the company grew by 52%.

Expanded supported SKUs: The number of SKUs that could be repaired increased by 21%.

A full 30,000 repairs in all were handled successfully in Odoo.

Decreased support resources: An 80% reduction was made in the resources required to support repair requests.

Warehouse optimization: Ventor PRO significantly enhanced warehouse operations, which minimized errors, reduced time spent, and made record keeping accurate. With this app, businesses can track inventory movements, set reorder points, and manage suppliers efficiently, all of which helps to prevent overstocking or stockouts, ensuring that necessary parts are always available when needed.

Margin targets: Consistently meeting margin targets was made possible by streamlined procedures.

Now, the client processes all business operations (including accounting) in one consolidated platform, which significantly simplifies management and streamlines workflows.

Enhanced client trust: As a result of transparent and efficient procedures, this client was able to win over more big corporate clients.

Quicker onboarding of new users or employees

Is your ERP slowing you down? Switch to Odoo and maximize your business.

Recommended articles:

- U.S. automotive company: 15X Growth with Odoo

- From Manual to Automated: How Odoo ERP Helped a Swiss IT Service Company to Grow Turnover 2.5 Times

- Odoo and Ventor solution for 27 Finnish stores: from manual inventory management to fully automated WMS

- How Odoo implementation automated 10 months of manual work and saved over €22K annually

- Odoo Success Story: From Budget Overruns to a Profitable Tech Company in Just 6 Months

- 10 most common questions to the official Odoo partner

0 Comments