Modern manufacturing is continually facing problems that we could not have thought possible just a few decades ago, and this explains the urgent need for end-to-end efficiency in manufacturing. The most common problems include low efficiency, lack of profitability, high defect rates, difficulties in meeting safety standards, and tight supply chain management. The introduction of new technologies is a major factor having a significant impact on success, and not every manufacturer can manage these technologies 100 percent effectively.

End-to-end efficiency in modern manufacturing involves optimizing all processes of production, from receiving raw materials to producing a finished product. This tangible concept’s importance cannot be underestimated, since it can lead to faster production, large cost savings, and high-quality products. There are numerous reasons why end-to-end efficiency matters in the modern manufacturing environment, with the most popular being rising customer expectations, supply chain complexity, and digitalization.

Rising Customer Expectations

Today’s customers are not satisfied with just getting their order fulfilled; they expect seamless, more personalized, and responsive service. It is crucial for manufacturers to pay close attention to end-to-end efficiency, as a failure to meet ever-increasing customer expectations can result in lost customers.

Supply Chain Complexity

This aspect is often a stimulant for achieving end-to-end efficiency and increasing the competitiveness of production. The more complex the supply chain, the more opportunities there are to optimize its processes, thus saving resources and improving customer service. Supply chain complexity promotes end-to-end efficiency by identifying weaknesses, reducing costs, optimizing processes, and improving competitiveness.

Digitalization

Successful modern businesses must learn to implement digital technologies in automating and optimizing processes, increasing decision-making speed, and significantly reducing costs. Digitalization is the reason for increasing end-to-end efficiency, as it increases process transparency and manageability, enables systems and data integration, and increases the company’s agility, which is essential for success in today’s competitive environment.

In this article, we will explain why end-to-end efficiency matters in modern manufacturing and delve deeper into Odoo solutions and their contribution to improving manufacturing processes.

Step 1: Supplier Management and Raw Material Flow

Supply chain management is a complex process that requires increased attention and specialized tools. The entire process can be divided into several stages, such as:

- Planning. This stage involves setting goals and the competent allocation of resources for the successful achievement of these goals.

- Procurement. This includes supplier selections, the choice of goods, and constantly monitoring relationships.

- Production. This covers competent resource management, process organization, personnel management, and optimization of the entire production system.

- Goods storage and delivery. Every manufacturer should have a properly equipped warehouse to store goods in the right conditions. Establishing logistical processes ensures that the goods are delivered to customers quickly in ways that are most profitable for you.

The importance of Odoo ERP integration for supply chain visibility cannot be understated, as it opens up new opportunities for manufacturing and helps to control end-to-end efficiency. Odoo offers real-time inventory tracking across different warehouses, enables efficient production planning, and provides tools for improved communication with suppliers.

Managing the flow of raw materials from suppliers to production sites, when done correctly, minimizes costs and keeps the manufacturing process running smoothly.

Procurement Automation

Effective procurement management is the key to business prosperity. More companies are now automating procurement to increase transparency, reduce costs, speed up order processing, and improve efficiency. Odoo solutions are popular among modern manufacturing facilities since they allow for optimizing supplier relationships and procurement automation while increasing overall efficiency. This system provides quality tools for improved procurement management.

Odoo allows for the automatic creation of procurement requests when stock forecasts fall below a certain level. Automation with Odoo also facilitates faster search and comparison of suppliers and selection for you to quickly find the best offers.

Why is procurement automation so important? First of all, it manages costs and increases efficiency while avoiding human error and minimizing risks associated with procurement. In addition, Odoo allows manufacturers to customize procurement routes and determine how goods should move between warehouses and other locations.

Step 2: Equipment Automation and Process Integration

MES (Manufacturing Execution System) and IoT in production process control are critical factors for improving production performance and controlling end-to-end efficiency. MES is a software that is designed to track, coordinate, and optimize manufacturing processes. These systems are important tools for production digitalization, as required in a modern environment.

The main functions of MES include:

- production processes control

- material and product tracking

- planning and distribution of tasks

- quality control

- analysis and reporting

IoT (Internet of Things) has a strong influence on the modern manufacturing sphere. Simply put, interconnected devices and sensors collect and exchange data, which is transforming traditional manufacturing sectors into innovative, advanced production industries.

IoT is an important tool in equipment automation as it allows for real-time monitoring of equipment condition, predicts potential malfunctions, and schedules preventive maintenance. These functions help to avoid serious breakdowns and improve personnel safety.

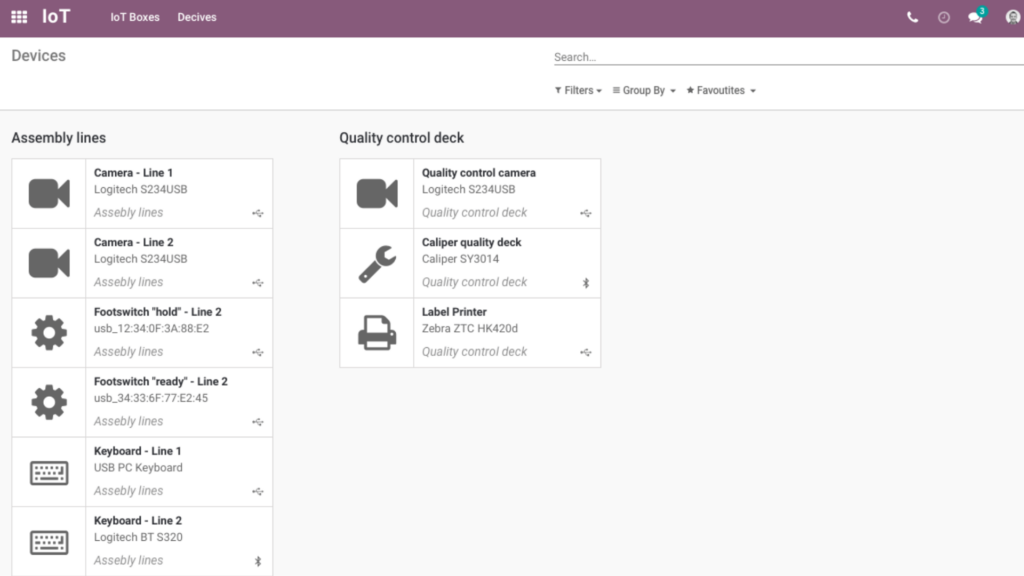

Odoo IoT

Odoo is a set of open-source business applications that cover the needs of any company. IoT is one of the Odoo modules that helps to connect any external device (quality measurement tools, cameras, printers, HID devices, weight scales, etc.) via Wi-Fi, USB, Bluetooth, or HDMI.

IoT Odoo ensures that your devices are fully integrated with your current business processes, greatly increasing productivity and simplifying data transfer.

How Odoo Solutions Simplify Process Control

The Odoo system is one of the market leaders in ERP solutions for manufacturing facilities. The main advantage of this system is the integration of multiple processes into a single platform, while the modular structure of Odoo allows you to add modules according to the needs of your business. The main tools for controlling production processes include automation, optimization, monitoring, analytics, and reporting. Now let’s look at them in more detail.

Process Automation

Automation of production processes is the introduction of modern technologies in order to minimize human influence on routine operations. Odoo allows you to automate all repetitive processes, allowing your employees to save resources and focus on more strategic tasks. For example, automation across supply chain stages improves collaboration, reduces costs, and enables companies to be more competitive in the market.

Process Optimization

The main objectives of optimization are to reduce the cost of production and, at the same time, to ensure high quality. The Odoo system does a good job of integrating the various stages of production, thereby increasing efficiency and profitability.

Process Monitoring

Odoo provides tools to track manufacturing processes progress in real-time. As a result, companies know exactly what to look for and are able to make quick decisions to prevent failures.

Step 3: Assembly, QA, and Real-Time Monitoring

The goal of any business is to bring profit, and, accordingly, the goal of any manufacturer is to provide high-quality products. In today’s highly competitive environment, an enterprise has no chance of existence with poor-quality products.

Assembly line quality assurance, whether visual inspection or carried out by specialized automated systems, is a complex process involving various methods to prevent defects and increase customer satisfaction. Its main objective is to ensure that the products manufactured meet the specified requirements.

How Does Odoo Contribute to Improving Quality and Minimizing Errors in Manufacturing?

Odoo can safely be called the quality management software you can rely on. A whole separate module has been developed that encompasses all aspects of quality control. Odoo Quality is an excellent tool for eliminating the root causes of costly defects and ensuring high-level quality throughout the entire product lifecycle.

Checkpoints

Odoo provides tools for automated creation of quality control points. This ensures regular inspections and the timely detection of possible non-conformities.

Notifications

The Odoo system allows for the creation of notifications when product defects are detected, so that you are able to respond immediately and correct the problem. In addition, you can also suggest preventive measures.

Quality Assurance

By implementing Odoo, you can choose from a huge number of available types of quality checks, thus ensuring proper quality control of all your products. What is more, you can create and customize interactive checklists for your employees.

Reporting

Odoo provides detailed statistics regarding the quality inspection status and the main causes of product defects. This allows more accurate and informed decision-making to improve this aspect of manufacturing.

Odoo also provides tools for real-time manufacturing monitoring, leading to problem area identifications and minimizing production errors.

Step 4: Packaging, Warehousing, and Internal Logistics

Well-organized warehouse processes, as main components of efficient manufacturing operations, speed up order processing, improve inventory control, increase efficiency, facilitate employee work, and bring many other benefits that will affect your company’s bottom line.

Warehouse and inventory optimization in factories is only possible with the implementation of modern technologies, such as advanced warehouse management systems and automated processes.

Packaging Optimization

A comprehensive approach aims to increase materials packaging efficiency and improve transportation reliability. In addition, packaging optimization is a means of enhancing brand image and improving customer service.

The Odoo system facilitates packaging optimization by enabling production planning based on customer orders. In addition, the system allows you to forecast sales volumes, which helps to avoid overproduction yet optimizes the use of packaging materials.

Automation of packaging and order processing processes, optimization of package size and shape, and integration with warehouse management systems contribute to improving packaging efficiency in manufacturing.

Warehousing Optimization

Warehouse optimization may include improving the spatial layout, automating processes, and implementing a security system. The Odoo system, although it is not a pure WMS, provides such functionality as a part of its modular system. Odoo warehouse management tools reduce losses connected to inventory shortages, speed up processes, optimize routes, and allow for tracking warehouse operations in real time.

This Odoo module provides for the automatic creation of orders to suppliers when inventory levels drop. This ensures smooth warehouse operation and prevents shortages. It also automates the goods receiving process and accelerates inventory, which minimizes downtime.

Odoo Warehouse optimizes warehouse space usage and ensures efficient goods placement, which speeds up order processing. This module also provides an instant warehouse search function, so you can quickly find the location of any item, even if you have multiple warehouses.

Internal Logistics Optimization

Packaging and internal logistics optimization are already a driver in reducing costs and creating a competitive advantage. The main goal of internal logistics optimization is to reduce the final product manufacturing cost and storage time by minimizing resources and financial costs while maintaining the required quality level.

Odoo solutions allow you to automate internal goods movement processes and optimize delivery routes. The system also enables you to track all movements of goods in the warehouse, including internal movements and shipments, which equates to internal logistics best practices.

Step 5: Last-Mile Delivery and Customer Visibility

Last-mile delivery in manufacturing is an essential part of the general delivery experience. In fact, since this is the last leg of a product’s journey, your customers will retain their perceptions of satisfaction with the product and your company’s service with this step. Last-mile delivery is the final but critical link in the supply chain, and modern manufacturers are constantly looking for new ways to make it convenient yet profitable.

Odoo ERP provides many tools to improve product delivery, including integration with various delivery services and tracking process statuses. Here are the key benefits of using Odoo ERP for manufacturing efficiency in the context of delivery:

- ability to customize delivery methods (courier delivery, self-delivery, or mail delivery) and set prices for them

- automatic generation of delivery orders based on sales orders and stock availability

- integration with shipping services to automatically calculate shipping costs, create delivery notes, and track shipments

- ability to track the delivery status of orders, such as the product location and expected delivery date

- tools for improved logistics management, including product tracking, delivery routing, and warehouse management

Last-mile logistics challenges and solutions play a critical role in the creation and maintenance of a positive company reputation, since challenges such as high costs, customer expectations, and even traffic congestion can be quickly and efficiently resolved with Odoo ERP.

Tracking and SLA (Service Level Agreements) management in manufacturing deliveries are critical to increasing customer trust and loyalty, identifying potential risks in a timely manner, and improving operational efficiency. Odoo simplifies the SLA process by allowing for:

- creation of a new SLA policy

- defining criteria for an SLA policy

- setting a target

- quick calculating and meeting deadlines

- analyzing SLA performance

Odoo tools significantly improve customer visibility through:

- centralized customer data storage

- automated communication through emails and notifications

- customer contact management

- personalized interactions

Discover How to Optimize Manufacturing with Odoo!

Conclusion

ERP system implementation and successful management is a required business development step for modernizing manufacturing processes. Such systems provide unified manufacturing data management within a single database containing all necessary information.

A reliable ERP system gives full control over end-to-end efficiency, as it ensures efficient interaction between all departments of the company, allows you to plan production while considering available resources and lead times, and leads to the automation of many processes, which minimizes risks of errors and ensures cost reduction. In addition, a unified data vision in manufacturing ERP systems enables fast and efficient decision-making and ensures transparency of all processes.

Odoo ERP is the choice of many manufacturers today because of its modular structure, flexibility, customizability, and availability of many other tools. The huge number of successful Odoo case studies in the manufacturing industry proves that this ERP system is suitable for manufacturing facilities of any size and purpose.

Recommended articles:

- From Manual Operations to a Smart Warehouse: How WMS Handles Growth Challenges, Reduces Costs, and Enhances Your Logistics Efficiency

- How to create a warehouse map and upload it to Odoo

- Half a million Euros’ profit from Odoo ERP integration – a high-end cigar business success story

- Odoo inventory optimization for a Baltics packaging supplies retailer, PaperSeal

----------------------------------------------------------------------

Education: Bachelor's degree.

----------------------------------------------------------------------

Experience:

Marketing manager

VentorTech

----------------------------------------------------------------------

Current position: Marketing manager VentorTech

----------------------------------------------------------------------

B2B Marketing

Google Tag Manager and GA

0 Comments