“Return on investment (ROI) is a performance measure used to evaluate the efficiency or profitability of an investment.”

Investopedia

Three key applications of ROI

On average, businesses invest between 1% to 4% of their annual revenue into an ERP implementation project itself, not counting the ongoing maintenance and upgrades. This percentage varies based on several factors, including the business size, the ERP system’s complexity, and the specific industry. For a Small to Medium-Sized Business (SMB), the share might be closer to the higher end of this range (2% to 4%) due to the relatively smaller revenue base and the need to integrate multiple business functions with limited internal resources. A large enterprise with more substantial revenue streams might allocate a smaller percentage (around 1% to 2%).

Justification

Such a big investment requires a robust financial justification for which ROI is the major tool.

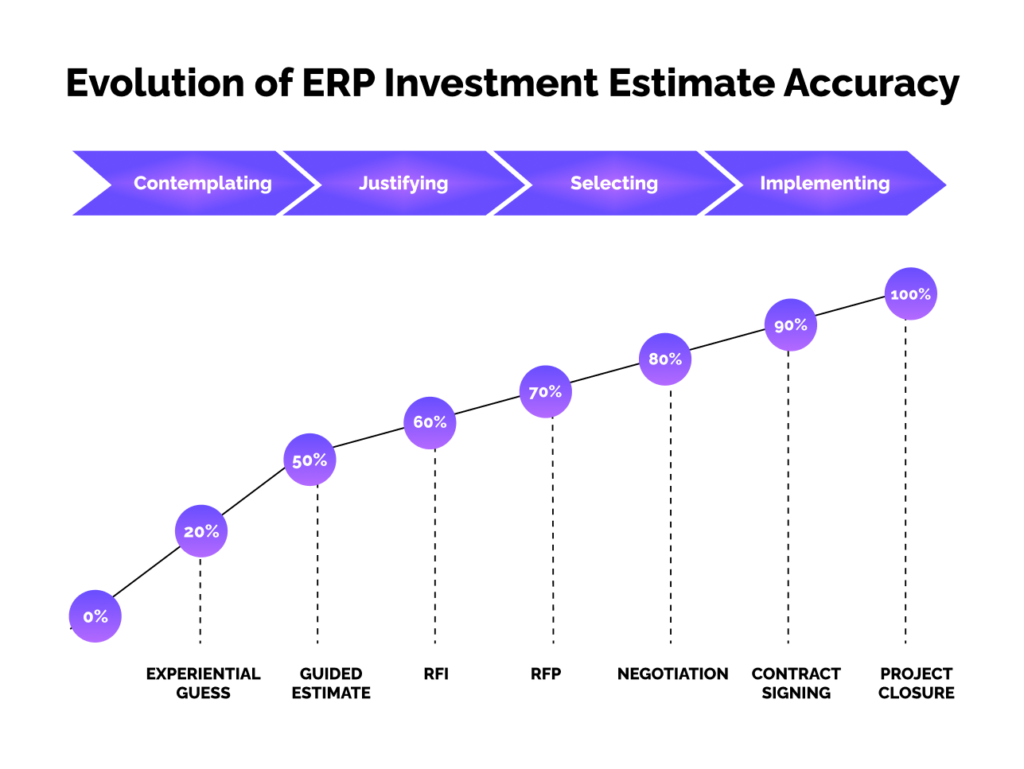

In the initial “contemplating” phase a high-level ROI can serve as an impetus for engaging into an ERP project, where the ROI estimate does not have to be precise, but convincing enough so that, with the acknowledged margin of error, it is still clear that exploring the ERP subject further makes a lot of business sense. This article touches on evaluating ERP implementation costs at different stages of the journey, including early justification.

Closer to “go-live”, an ROI becomes a clear commitment, a symbolic or even a literal contract binding stakeholders from various participating business functions and IT to concrete financial outcomes.

Evaluation

ROI is also essential for evaluating the success of an ERP implementation project. The horror stories of failed ERP projects are widely known. One famous example forever etched into ERP history is Hershey Foods’ 19% drop in profits stemming from a failed ERP implementation. But, according to Deloitte, more than 50% of ERP implementations, while not being as catastrophic as Hershey’s, still fail to achieve their planned business objectives. A significant reason for that is poorly designed objectives at the start. ROI is a major financial measure anchoring those business objectives with reality and an opportunity to evaluate the results.

Engagement

ERP implementation, as a big investment, goes above and beyond the traditional budget-based IT funding model, making most technically inclined IT leaders uncomfortable in dealing with its financial aspects. And while traditionally ERP is considered to be an “IT project,” this remains to be a very arguable proposition, since ERP deployment entails deep and wide transformational business changes, while its deployment is doomed if those changes aren’t embraced by employees or supported by leadership.

As a matter of fact, a lack of executive sponsorship and involvement consistently shows up as the topmost reason for ERP project failures; such a situation results in insufficient resources, a lack of business strategy alignment, and reduced accountability.

An ROI is a tool through which IT can engage with executive leadership, solicit their support, and make them accountable for ERP deliverables. An ERP ROI should be part of an ERP strategy roadmap—a S.M.A.R.T. long-term plan linking ERP goals with strategic business objectives through measurable performance indicators to help advance an organizational vision.

ROI calculation

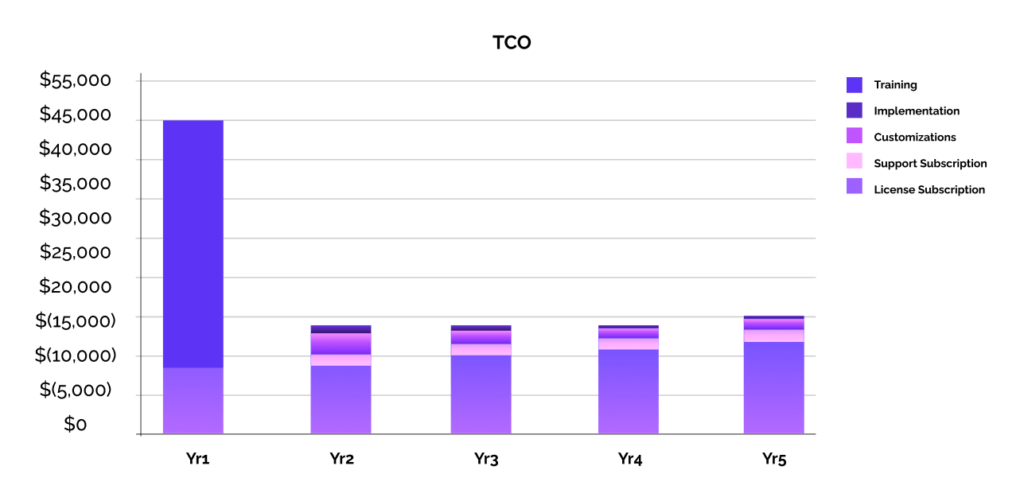

ROI evaluates monetary gains (or returns) achieved (or planned to be achieved) from ERP use against the costs of implementing and maintaining it. The primary sources of those gains come from increased operational efficiency through process automation and higher employee productivity, better decision-making, enhanced customer satisfaction, and improved regulatory compliance. The costs of implementing and maintaining an ERP are typically called Total Cost of Ownership (TCO = purchase price + implementation costs + operating costs for 5–10 years).

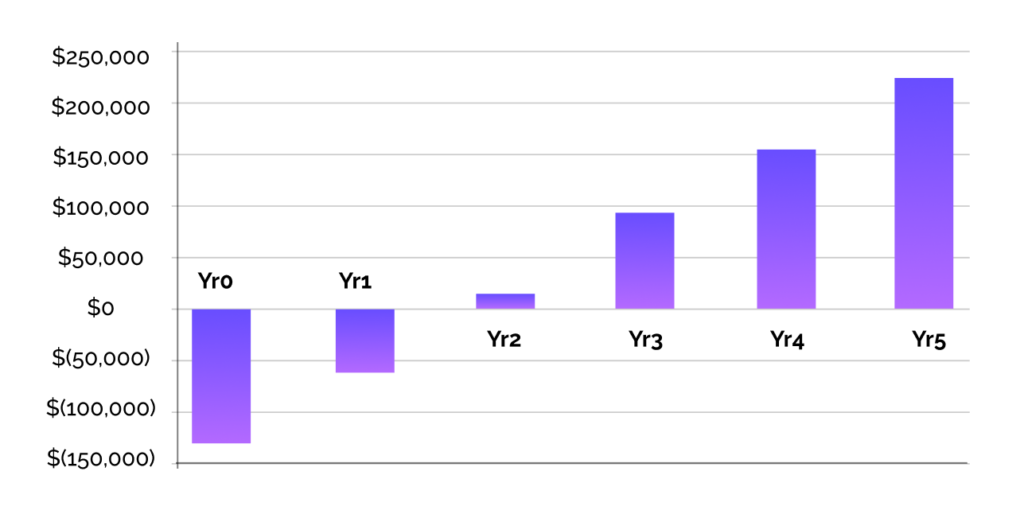

An ROI for any given implementation can vary widely (and can be negative with ERP implementation failures), but most organizations can expect it to range from 100% to 500% over a period of 1 to 5 years. This means that for every dollar invested, the return can be between 1 to 5 dollars in 5 years.

That’s a very rough estimate, and what makes more sense as a target is the so-called ROI payback period—the time it takes to achieve a positive ROI balance or break even with the project investment. A smaller dynamic private company can target a short 2-year (or even 1-year, especially in retail) payback period. A medium size manufacturer might go up to 4 years. In the public sector, including government agencies, municipalities, and public health systems, the targeted and fully realized timeline from an ERP implementation can be significantly longer, ranging from 5 to 10 years. This is due to the complexity of public services, regulatory requirements, and a different sense of sourcing the money and benefiting from investing in systems, etc. in general.

As a practical example of choosing “the right ERP” from an ROI perspective, the Odoo ERP applications suite is very attractive, especially for SMBs, because of the licensing simplicity and low (as compared to most other ERP offerings) initial investment with a straightforward path for gradual adoption. Those factors allow for a short payback period (often 6 to 12 months) with tangible operational cost savings and productivity increase—a very encouraging incentive for scaling up the Odoo implementation to its full potential and maximum gains.

How to convert ERP benefits into an ROI numerator

The subject of ERP benefits is a complex matter that goes outside of this article’s scope. As mentioned previously, those benefits or returns come from increased operational efficiency, process automation, higher employee productivity, better decision-making, enhanced customer satisfaction, improved regulatory compliance, and so on. Not all of them can be converted easily and directly into hard currency, and hence, ROI; but with some systemic approach, it can be done to an extent sufficient for gauging ROI with acceptable accuracy.

Here’s a down-to-earth example:

The ”How to estimate ERP costs at the beginning of the journey?” article goes through a simple real-life example of a Canadian tile distributor/installer who contemplates optimizing his company’s warehouse and order management operations by ERP and barcode scanning automation while also pondering the costs to do so. The story does not mention the attempt at “ROI on a napkin” that took place there too.

It was roughly estimated (with virtually no exploration of the business’s needs and requirements) that, within the first 2 years of the suggested Odoo Inventory application use, the implementation project costs would be in the $8,000–$40,000 range. The top of the range ($40,000) was conservatively assumed as an investment—subject to be offset by the ERP returns.

One of the pain points of this small business was warehouse picking errors, where 4–5 times a week, manually filled skids would go out with the wrong product, resulting in a domino effect of delayed installation (then affecting other scheduled installations), unduly product moves with damages, reorders, rework, and, of course, unhappy customers.

Achieving two fewer picking errors per week (reducing the number of mistakes by half) is not a very ambitious target when it comes to going from paper-based manual order picking to barcode-enabled scanning, where a system would prevent an operator from picking the wrong part. That pessimistically expected improvement translates roughly to 100 fewer errors per year. The cost of each error in its direct (product and time loss, rework) and indirect (customer satisfaction, staff morale) consequences has been estimated to be, at a minimum, $500 but likely significantly higher on average. That means that Oddo Inventory with scan gun automation is expected to yield at least $50,000 of annual savings for that company just on picking operation alone! And that beats the ROI $40,000 payback target in its first year.

The next opportunity was the warehouse “transparency,” which meant knowing with relative confidence what was in the warehouse and having that information at the fingertips of the back-office employees. Much of the product (circa 20% of the warehouse) was “lost” and taking up room in an already jam-packed warehouse. Decreasing that wasteful load to, for example, 5% with improved visibility of what is in the store would undoubtedly result in more substantial benefits that (when converted to $$) could be added to the ROI numerator.

And the list goes on…

There are libraries of so-called Key Performance Indicators (KPIs), which are extremely helpful for identifying and numerically expressing opportunities like the aforementioned two. One of them, kpilibrary.com, is no longer functioning but still offers a substantial list of useful community-collected KPIs for various industries and business functions.

Conclusion

ROI measures the efficiency of ERP deployment in financial terms by dividing the financial benefits of ERP by its costs (implementation or TCO) over a predetermined period of time (desired payback period, expected ERP lifecycle, or any number of years set by an organization’s financial or project management practices).

An ROI for any given implementation can vary widely, but most organizations should expect a 100%–500% return over a period of 1–5 years.

ROI, as a specific fiscal measure, is an important tool to justify ERP implementation from its early contemplation stages up to evaluating post-implementation results, as well as to solicit business engagement in the ERP project with executive buy-in.

Have difficulty calculating ROI of your ERP?

Recommended articles:

- How to estimate ERP costs at the beginning of the journey?

- Odoo Enterprise License Pricing and How to Reduce Cost

- The True Cost of Odoo ERP: Pricing and Ownership Insights

- Top 10 Reasons to Choose Odoo ERP for Your Business

- 10 most common questions to the official Odoo partner

- WMS implementation guide for SME

----------------------------------------------------------------------

Education: MSc, MBA

----------------------------------------------------------------------

Experience:

Director, Research & AdvisoryDirector, Research & Advisory

Info-Tech Research Group

Global IT Director, CIOGlobal IT Director, CIO

Napoleon Group of Companies

----------------------------------------------------------------------

Will do any work for SpaceX for free

0 Comments