In a modern environment, ERP (enterprise resource planning) systems in manufacturing provide for an indispensable tool that simplifies numerous processes and enhances productivity. Companies that still underestimate the importance of ERP systems consistently face problems such as low production efficiency, high defect rates, suboptimal capacity utilization, and inadequate quality control.

In this article, we will discuss the importance of an ERP system for manufacturing and provide detailed information about the three main areas of influence. We will also provide real-world ERP use cases manufacturing, that will once again demonstrate the importance of ERP solutions for small and large manufacturers.

Why ERP Is Crucial for Modern Manufacturers

For modern manufacturers, an ERP system is the critical “nerve center” for effective functioning and maintaining competitiveness in the market. Such solutions offer the opportunity to integrate all business processes into a single, convenient, and powerful system that helps address key challenges.

Business Process Automation

ERP for process automation in manufacturing allows companies to significantly reduce manual labor costs, increase production efficiency, and minimize errors, including those caused by human factors. Such a solution allows for the automation of key manufacturing processes, such as procurement, production, quality control, logistics, and distribution.

Unified Information Base

The ERP system brings all the essential information into a single environment. This information includes data on resources, inventories, production processes, orders, and interactions with suppliers and consumers. Many modern manufacturers choose Odoo ERP, as this solution combines many functions in one system, which gives a complete overview of all operations. A unified database allows for tracking the availability, movement, and resources usage in real time, thereby optimizing processes and significantly reducing costs.

Forecasting and Planning

An ERP system helps to forecast product demand, which optimizes production processes and ensures timely order fulfillments. A properly selected and configured ERP system also allows for high-quality; accurate planning of production resources, such as materials, personnel, and equipment; and optimized order fulfillment times, all of which lends to increased production speed.

Coordination Between Departments

The ERP system ensures effective interaction and data integration between the production department and other departments of an enterprise, such as marketing, finance, logistics, and others. This contributes to improved communication and faster decision-making.

Improved Transparency and Quality Control

The best ERP software for manufacturing companies (e.g., Odoo ERP) ensures quality control at all stages of the production process, from raw material acceptance to finished product release. This minimizes defect risks and allows management to better control the order fulfillment process, identify inaccuracies and eliminate them in a timely manner, and make informed decisions quickly. Results of process tracking and reporting in ERP systems leads manufacturers to realize a positive impact on the company’s reputation in the market.

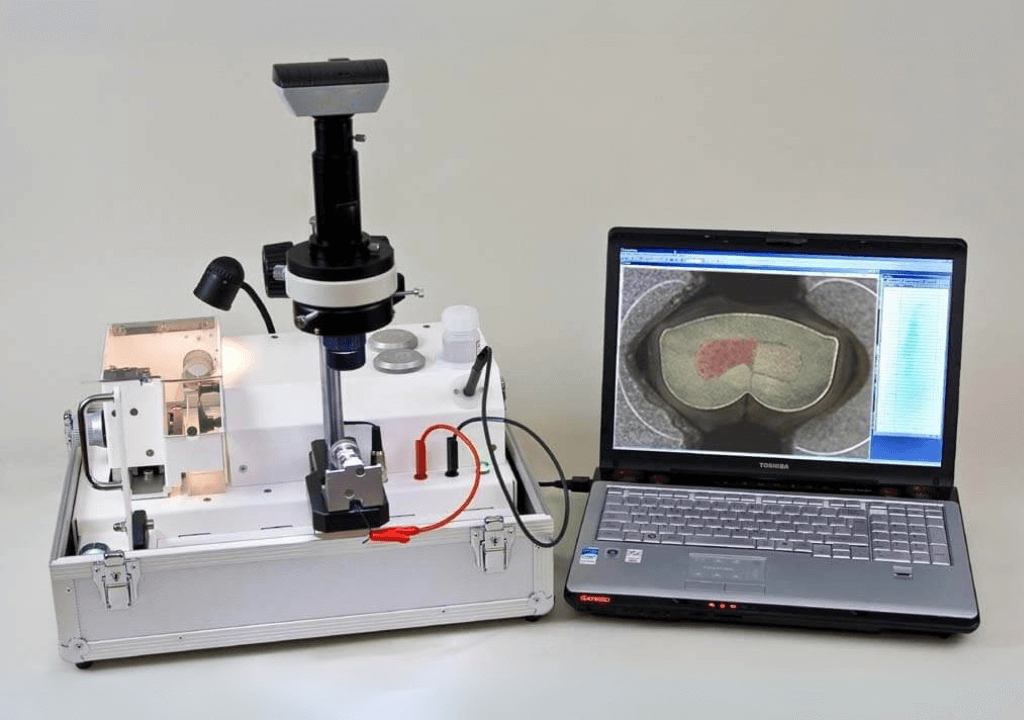

1. ERP for Equipment Manufacturing

ERP systems are critical for modern equipment manufacturers, as they provide data centralization, cost optimization, and integrated management of production processes, which significantly improves product quality and decision-making efficiency. In order to ensure that the ERP system fully copes with its tasks, it needs to be implemented correctly with attention paid to functionality, flexibility, and scalability. For many equipment manufacturing companies, Odoo ERP is an excellent choice, as the system consists of many modules that can be integrated and implemented together or separately, depending on a particular manufacturer’s needs.

Equipment manufacturers that work without an ERP system face many difficulties, which results in raised costs, lowered company competitiveness, and decreased customer satisfaction. Here are the most common problems signaling that your equipment manufacturing facility needs to implement a reliable ERP system.

Loss of Control Over Production Tasks

Routine tasks that are not automated in time often cause errors and delays in production. This forces employees to spend extra time correcting these errors, whereas with automation, they could spend time and resources on more strategically important tasks.

Low Quality Control

Without an integrated quality control system, it is hard for equipment manufacturing to detect defects and analyze root causes. In addition, the lack of a unified database leads to errors in equipment manufacturing cost calculations, inventory details, and lead times. This all together distorts the real picture of production activity and jeopardizes the standards and conformity of manufactured equipment.

Ineffective Coordination

Without the unified information system that ERP provides, production departments do not work in a coordinated manner. This introduces poor coordination and limited visibility into the production process.

If your equipment manufacturing facility is facing any of these problems, it is time for you to seriously consider implementing an ERP system as soon as possible. Odoo ERP is a popular choice among modern equipment manufacturers, and here is why:

- The system allows you to combine production and planning, and this ensures that each order is built correctly and delivered on time.

- Odoo ERP provides effective tools for production tracking and systems for product quality control.

- The system is open source, making it as flexible as possible and allowing you to customize it to meet the specific needs of your manufacturing and scale as those needs grow.

Thus, the implementation of a reliable ERP system in equipment manufacturing processes is guaranteed to result in increased efficiency, reduced errors, lower costs, and transparency of operations.

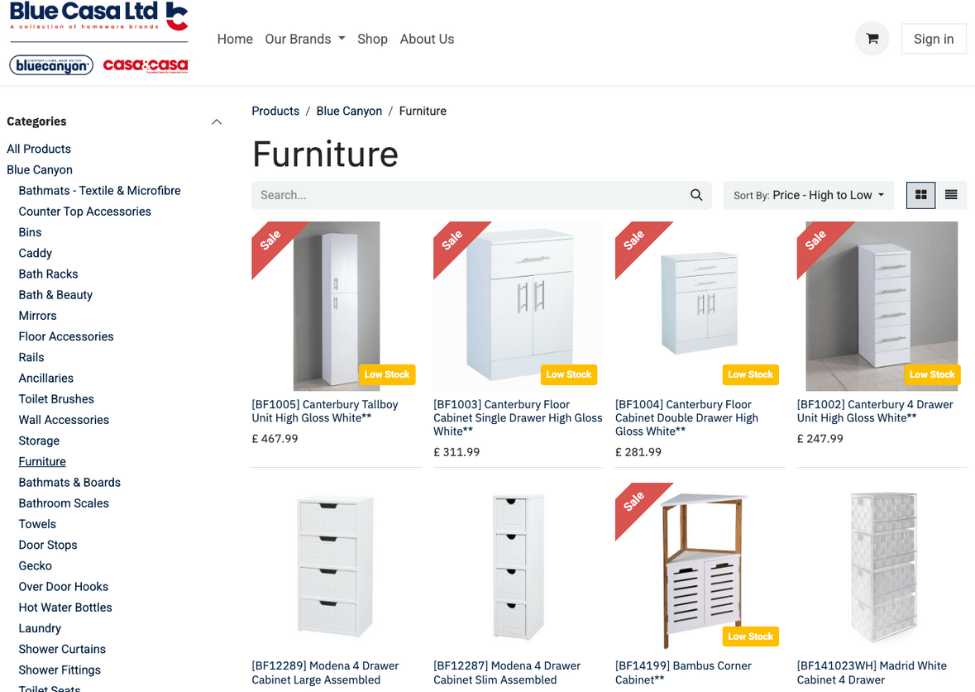

2. ERP for Furniture Production and Inventory

Furniture production is a complex process consisting of several stages, each of which has its own characteristics. A huge number of different material types and other components are used in the production and installation of furniture, so everything must be organized correctly for quality control. Thus, it is difficult to list all the ERP benefits for modern manufacturers, as the system reduces costs, optimizes business processes, and increases the efficiency of furniture manufacturing.

Production Management

The ERP system for furniture production must account for the specifics of working with different materials, such as wood, accessories, and fabric. With ERP solutions, you can create accurate production plans while considering important factors, such as deadlines and resource availability. In addition, such a system allows for effective monitoring of furniture units quality at every manufacturing stage. This guarantees that each finished product complies with customer requirements and production standards.

Inventory Management

High-level inventory management in furniture manufacturing plays a key role in order fulfillment speed, increased profitability, and improved customer satisfaction. The ERP system, such as Odoo ERP, allows you to monitor inventory movements in real time, control raw material balances, and prevent shortages and surpluses. Managing inventory efficiently is critical for furniture manufacturing, as it involves a huge number of materials, components, and finished products.

The implementation of ERP systems by furniture manufacturers allows them to remain competitive, increase process efficiency, optimize business processes, and reduce costs. In addition to production and inventory management in furniture production, ERP systems simplify management of many other furniture manufacturing processes, which we will discuss in more detail below.

- Financial management: automated accounting processes, budget creation and control, cost analysis tools.

- Order management: order processing automation, transparency in tracking order status, and simplification of coordination for raw material and finished product deliveries.

- Human resources management: the ability to plan employee working hours, tools for assessing employee performance, and the ability to organize employee training and development.

- Supplier management: tools for evaluating suppliers based on various criteria and for monitoring the supply of raw materials, as well as the ability to manage contracts with suppliers, ensuring compliance with contract terms.

- Report management: creation of detailed sales reports based on sales analyses according to various criteria, production reports, and tools for forecasting future needs and trends.

Thus, we can see that ERP for a furniture business includes a huge number of functions when we consider the possibility of automation and management of all processes in a single system.

3. ERP for Packaging Production Optimization

Packaging production optimization is critical for a company to remain competitive and keep its product relevant and compliant. Nothing helps packaging manufacturers optimize their packaging production processes more effectively than a reliable ERP system.

Features of automating key business processes in ERP include the following:

- Accurate accounting of raw materials and finished products

- Efficient production planning that accounts for materials availability

- Optimization of warehouse inventory balances

- Integration of all packaging creation and sales stages

Below, we have provided the advantages of the ERP system that prove its importance for packaging manufacturers.

Effective Process Integration

The ERP system integrates all departments, such as production, design, sales, logistics, and others, into a single information system. As a result, all data is stored, and the loss of important information is avoided. The elimination of rework and missed specs greatly affects product quality and delivery time.

Meeting Deadlines

Critical deadlines are considered in both order fulfillment and delivery, as packaging is an extremely important component of retail. An ERP system, such as Odoo ERP, automates the order fulfillment process, improves logistics, and speeds up product delivery. These automations will result in an improved customer experience and increase the company’s competitiveness in the market.

Effective Tracking of Material Utilization

Packaging production is a rather complex process that involves many aspects. From one angle, it includes many kinds of raw materials, such as adhesives, paper, or plastics. To better manage this variation, an ERP system allows you to control residual quantities and track the utilization of these materials. This helps to maintain balance in the warehouse and reduce the overhead costs.

Transform Your Manufacturing Operations with Odoo ERP!

Real Examples of Digital Transformation

Digital business transformation is an inevitable step that entirely changes the way processes are carried out, the interactions with your customers, and your company’s approach to resource management. The digital transformation process involves the integration of modern technologies into all aspects of an enterprise’s operation, which is extremely relevant today due to constantly changing market conditions, increased competition, and growing customer expectations.

Digital transformation with ERP systems provides centralized resource management, integrating all processes into a single platform. The tools provided by ERP allow for optimizing and automating basic processes. As a result, companies increase their efficiency and transparency, which makes them more competitive.

ERP-driven digital transformation in factories improves inventory management, provides a single source for information, simplifies workflows, and takes customer and supplier relationships to a higher level. The proof of this is seen in the many successful case studies of ERP in manufacturing, the most vivid of which we will provide in the next part of this article.

But before we get to the manufacturing ERP integration examples, we want to draw your attention to how ERP-driven digital transformation influences production efficiency. Here are some critical considerations:

- Cost reduction through improved resource management and process optimization

- Increased transparency of production processes and their manageability

- Elevated productivity by automating processes

- Improved product quality and minimized errors through enhanced control at all stages of production

- Accelerated order fulfillment through effective planning

Examples of our manufacturing clients who use Odoo ERP:

Coldex 🇫🇮 – Leading manufacturer of chilling and freezing cold storage solutions in Finland

SM Contact Tech 🇫🇷 – Electronics equipment manufacturing in France

Chemical House 🇦🇺 – Chemicals manufacturing in Australia

Led Ner SAS 🇫🇷 – Electric lighting equipment manufacturing in France

Recommended articles:

- Odoo inventory optimization for a Baltics packaging supplies retailer, PaperSeal

- How Odoo implementation automated 10 months of manual work and saved over €22K annually

- Key Performance Indicators (KPIs) and their Role in Successful ERP Implementation

- What Is ERP ROI and Why Is It Important?

- Odoo Implementation Steps

- The True Cost of Odoo ERP: Pricing and Ownership Insights