Introduction

Every successful trading or manufacturing company, at a certain stage of its development, encounters the need for logistics optimization. What began with a small warehouse, a van, and a couple of ‘jack-of-all-trades’ specialists evolves into a complex system requiring precise management as operational volumes increase. Initial methods relying on verbal instructions and Excel spreadsheets quickly reach their limits, becoming a bottleneck that constrains business development.

Many companies postpone their transition to professional warehouse management tools, relying on employees’ ability to ‘figure something out’ and compensate for their coworkers’ errors. However, this approach is risky and not scalable. At a certain point, reality becomes evident: for sustained growth, enhanced operational efficiency, and stringent cost control, a significant change is necessary—the implementation of a Warehouse Management System (WMS). When you find your business in this position, you want to be ready with scalable solutions that minimize risk and maximize results. Such changes can overtake businesses quickly, so let’s delve into the indicators signaling the need for a WMS and how our customized solutions can address your specific operational challenges.

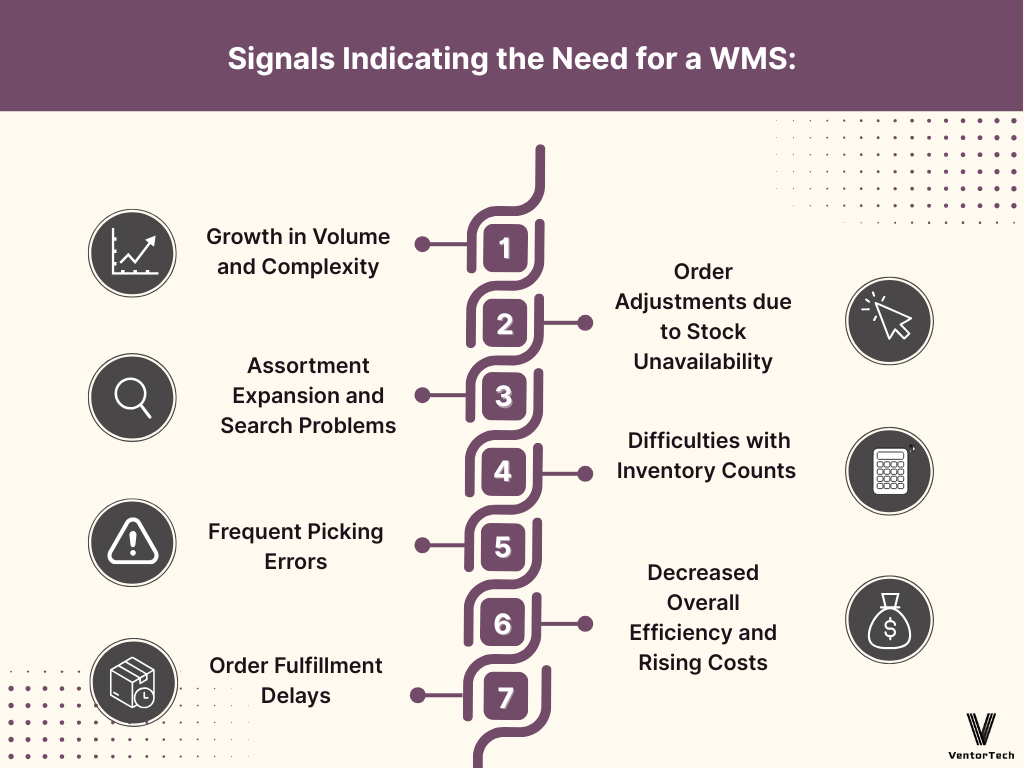

Signals Indicating the Need for a WMS

How can you determine if your warehouse operations have outgrown current management methodologies and urgently require automation via a WMS? Let’s explore this together. When other companies reach this critical juncture, they reach out to us, because our company specializes in the development and implementation of such systems. We empower businesses to transform their warehouses from cost centers into strategic competitive advantages. So we know that several clear indicators for needing a WMS are commonly faced by growing companies.

Growth in volume and complexity

Increased inventory levels, assortment expansion (more skus), a higher volume of orders, and increased warehouse transactions make manual inventory control using Excel or similar rudimentary systems extremely error-prone and labor-intensive. Data entry mistakes become frequent, information loses its timeliness without real-time visibility, and data validation consumes excessive resources. Scalability under such conditions is practically impossible.

Assortment expansion and search problems

As the range of skus (stock keeping units) increases, locating specific items often becomes significantly challeng, often referred to as a ‘quest’. Employees spend disproportionate amounts of time traversing the warehouse (non-value-added travel time), leading to decreased productivity, even when staff appear busy. The company becomes reliant on the ‘tribal knowledge’ of individual long-term employees who intuitively ‘remember’ item locations.

Case Example: In a company distributing home appliances, only two warehouse operators could accurately identify specific washing machine models and knew their precise location within the racking system. These individuals strongly resisted the WMS implementation. Consequently, an external firm was engaged to conduct inventory counting; their specialists compiled the item master data and performed a full inventory of all bin locations. On the designated system go-live day, these two key operators failed to report for work. However, because the WMS already contained accurate product and location data, all pending orders were successfully picked by other operators reassigned from different storage zones. Critically, the orders were picked for the delivery vehicles and dispatched ahead of the scheduled departure times.

Frequent picking errors

Incorrectly picked orders (mis-picks) result not only in direct financial losses due to inventory shortages or surpluses but also lead to lost sales, diminished customer satisfaction (potentially driving customers to competitors), and increased costs associated with returns processing (reverse logistics). Furthermore, manual paper-based post-picking checks are time-consuming and notoriously unreliable in catching all errors.

Order fulfillment delays

Order picking and dispatch processes consistently taking hours, or even extended over days, is a definitive signal of process inefficiency. Lost paperwork between the office and the warehouse floor, information availability delays, and suboptimal travel paths for warehouse personnel all contribute to missed deadlines and service degradation.

Order adjustments due to stock unavailability

Discovering during the picking process that an ordered item is not physically present, despite inventory records indicating availability, severely erodes customer loyalty. This scenario carries a high probability of not only immediate order cancellation but also the permanent loss of the customer relationship.

Case Example: During a WMS implementation at an electronics distributor's warehouse, the initial inventory count revealed a 'surplus' item—a mobile phone that had been “lost” within the system for nearly four years. By this time, the item was completely obsolete, representing a sunk cost. It had remained undetected on a top shelf rack for the entire period.

Difficulties with inventory counts

Under manual control systems, conducting a full physical inventory count becomes an exceedingly complex and disruptive undertaking. This function is typically performed infrequently (e.g., annually), requires several days to complete, and necessitates a complete halt of warehouse operations. The accuracy of such manual counts is often questionable.

Decreased overall efficiency and rising costs

Operational costs (personnel, facility lease/costs, error handling) increasing at a faster rate than business turnover or throughput serves as a critical warning sign. The root cause often lies in chaotic, non-standardized, and unoptimized warehouse processes.

If you recognize your operational reality in at least two of the points detailed above, then actively evaluating WMS implementation for your company is highly advisable.

Curious About Implementing a WMS but Don’t Know Where to Start? Our Consultants Are Here to Help!

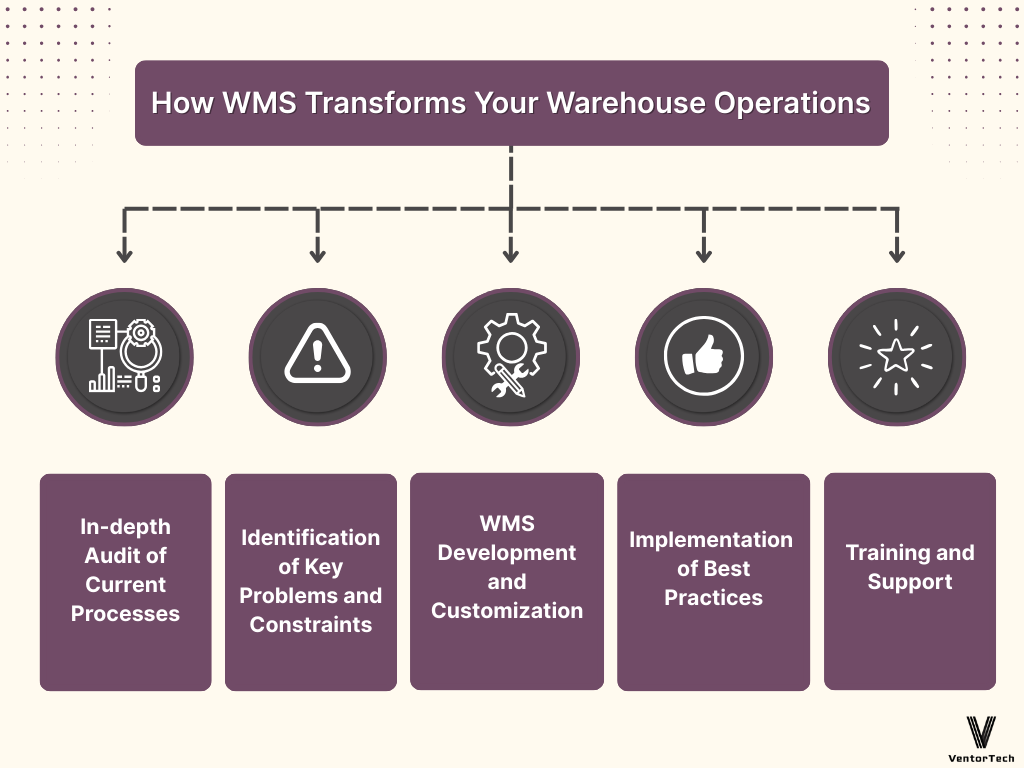

How WMS Transforms Your Warehouse Operations

A WMS implementation involves far more than just installing software; it comprises a comprehensive project focused on the strategic reorganization and optimization of your company’s warehouse processes. We approach this systematically by leveraging our deep expertise accumulated in both Odoo WMS development and hands-on, practical logistics management.

In-depth audit of current processes (i.e., an ‘as-is’ analysis)

Before proposing any solution, we conduct a thorough investigation into how your warehouse operates in reality. We analyze actual workflows and practices, not solely relying on potentially outdated documented procedures (SOPs). Discrepancies between documented and actual processes are a frequent contributor to implementation challenges. Our audit identifies operational bottlenecks, the root causes of errors, and systemic inefficiencies.

Identification of key problems and constraints

Through the audit process, we pinpoint your primary operational pain points, which might be any of the following:

- High error rates

- Frequent mis-picks

- Significant losses due to products expiring

- Inefficient space utilization

- Extended onboarding times for new hires

- A lack of real-time operational visibility

We also identify critical constraints that could impact the project scope or timeline.

e.g., physical space limitations—exemplified by a pharmaceutical client case where our audit identified suboptimal procurement practices contributing to space issues, ultimately enabling a 3500 m³ reduction in storage footprint.

WMS development and customization

Based on the detailed audit findings, we configure and customize our WMS solution based on Odoo ERP to precisely meet your unique operational requirements. Our system’s core functionalities include:

- Directed storage (bin location system): Maintaining precise, real-time knowledge of the storage location and quantity for every sku.

- Barcode, QR code, or RFID-based management: Utilizing handheld data terminals (mobile computers/rf scanners) for all key warehouse transactions—including receiving, put-away, picking, dispatch, and inventory counts—which drastically minimizes human error and accelerates process execution.

- Put-away and picking optimization: The system intelligently suggests optimal bin locations for incoming stock based on predefined rules (e.g., velocity, storage requirements) and calculates optimized travel paths for order pickers to minimize travel time and increase picking efficiency.

- Batch/lot and expiration date tracking (FEFO/FIFO/LIFO): Provides robust tracking and management of inventory attributes critical in many sectors (e.g., food & beverage, pharmaceuticals). Our WMS automates control-based rules, like first-expired-first-out (FEFO), first-in-first-out (FIFO), or last-in-first-out (LIFO).

Case Example: Post-WMS implementation at a beverage distribution company, losses attributed to expired product write-offs were reduced by 85%.

Case Example: A distributor was contractually obligated to supply retail chains with products meeting specific minimum remaining shelf-life requirements. Manually tracking this across diverse products and multiple retail contracts had proven to be extremely complex and error-prone. The WMS automated this compliance check, eliminating product refusals by retailers due to unmet shelf-life terms.

- Storage condition control: the system enforces predefined storage requirements, preventing operators from placing items in locations that violate temperature controls, hazardous material segregation rules, or other specified conditions.

Implementation Example: At a dairy producer's facility, the WMS automated the critical transfer process for products moving from a cooling chamber to a main storage chamber. System-generated transfer orders were created automatically for each batch based on its specific processing requirements. The WMS logged the time each batch entered cooling, generated the transfer task for the precise required time, and systemically blocked any attempt to execute the transfer prematurely.

- E-commerce and ERP integration: Facilitates the provision of accurate, real-time inventory data availability to e-commerce platforms and ensures seamless, bi-directional data exchange with your core enterprise resource planning (ERP) system, such as Odoo.

- Inventory count module: Supports efficient and accurate inventory counting methodologies, including full physical inventories and cycle counting programs, often without requiring a complete halt of warehouse operations.

- Resource and personnel management: Includes tools for monitoring employee productivity metrics, managing task assignments, and balancing workloads across the warehouse team.

Implementation of Best Practices

Our approach for Odoo WMS architecture incorporates globally recognized best practices in warehouse logistics. By implementing our system, you gain access to field-proven, highly effective processes, which are then fine-tuned to your specific operational context.

Training and Support

We provide comprehensive training for your personnel on system operation. We include ongoing support throughout all phases of the implementation project (design, configuration, testing, go-live) and we continue with you into post-implementation operational use. As highlighted by the case of resistant warehouse operators, a properly implemented WMS coupled with effective training enables widespread positive change support with rapid proficiency for new team members.

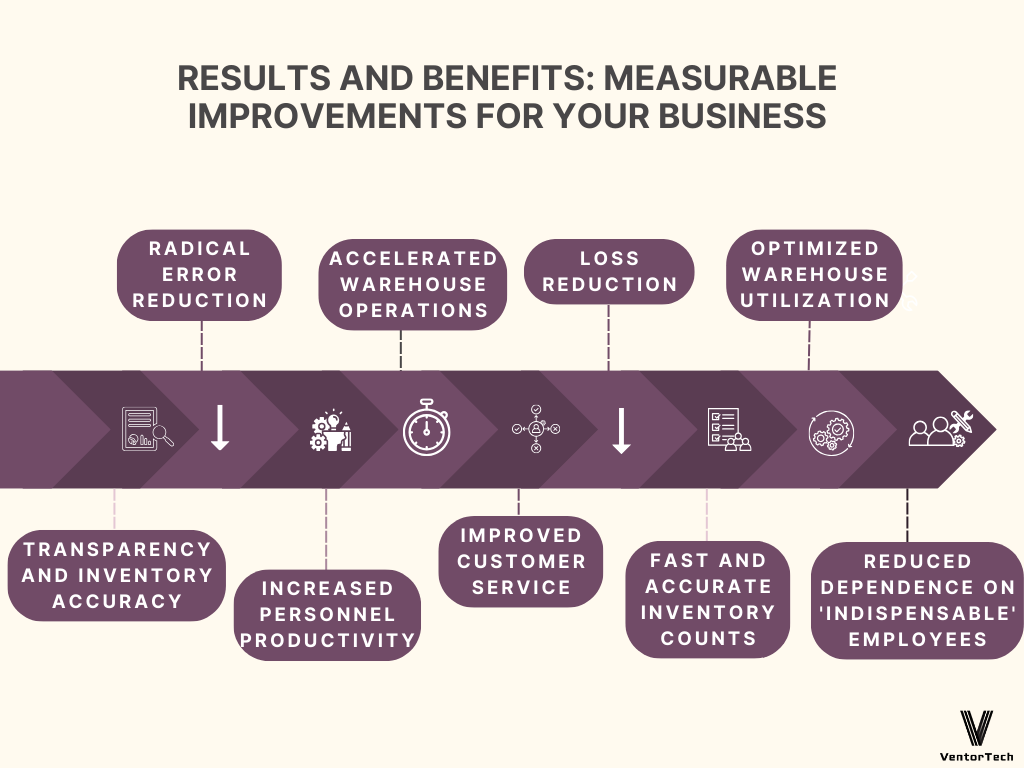

Results and Benefits: Measurable Improvements for Your Business

A successful WMS implementation delivers tangible, measurable results that directly enhance your business’s profitability and competitive positioning. Based on the outcomes achieved by our diverse client base, you can typically expect:

- Radical error reduction: Achievement of high levels of operational accuracy, with picking accuracy often reaching 99.5% or greater (a common performance target is less than 1 error per 10,000 picking lines/operations), along with significant minimization of mis-picks and inventory shortages.

- Accelerated warehouse operations: Reduction in order cycle times (picking and dispatch) typically ranges from 20–50% or more, leading to increased warehouse throughput capacity and improved customer service.

- Loss reduction: Automated tracking and management of expiration dates and batch/lot numbers dramatically reduces write-offs associated with expired or obsolete stock, often by 80–90%.

- Optimized warehouse utilization: Directed storage logic and intelligent put-away strategies lead to more effective use of existing warehouse cubic capacity, potentially yielding space savings of up to 30%.

- Transparency and inventory accuracy: Establishes near real-time visibility and maintains high levels of inventory record accuracy (typically exceeding 99.5%), providing the reliable data foundation necessary for effective procurement planning, demand forecasting, and sales management.

- Increased personnel productivity: Optimization of travel paths, task interleaving, and system-directed work typically results in labor productivity improvements ranging from 15–30% or more.

- Improved customer service: Delivers consistent accuracy and speed in order fulfillment, enhancing customer satisfaction and enabling the reliable execution of specific customer requirements (e.g., adhering to strict remaining shelf-life mandates for retail clients).

- Fast and accurate inventory counts: Transforms inventory counting from a major disruption into a more routine, efficient, and accurate operational task (especially with cycle counting).

- Reduced dependence on ‘indispensable’ employees: Processes standardization and the intuitive nature of working with handheld terminals significantly reduce the learning curve and onboarding time for new warehouse personnel.

Experience the Benefits of a Successful WMS Implementation!

Conclusion

Implementing a modern WMS (e.g., based on Odoo ERP) represents a strategic investment in the future growth, operational control, and overall resilience of your business. If you are currently grappling with challenges related to warehouse inefficiency, persistent errors, inventory losses, and operational constraints hindering growth due to outdated management methods—then the time to act is now. Our company possesses the deep industry expertise and robust technological solutions required to help you elevate your logistics operations to the next level.

Don’t delay with the optimization of your warehouse. Contact us today to discuss the specific challenges you are having with your operations, and let’s explore how we can help you resolve them. We will show you how our Odoo ecosystem can significantly enhance the efficiency and effectiveness of your business.

Recommended articles:

- U.S. automotive company: 15X Growth with Odoo

- How a US Repair Company Scaled Up After Migrating from a Legacy System to Odoo

- Is it the right time to integrate WMS into the company?

- How to build picking routes in your warehouse for walking minimization

- Print product labels from Odoo directly to a printer with 1 click via Odoo Direct Print PRO