Company Name: Under NDA

Country: US, Chicago, IL

Industry: B2C reseller

Company size: 51–200 employees

VentorTech solutions: Odoo implementation, Ventor PRO, Odoo Direct Print PRO

Goal: Optimize receiving workflow

“This small feature brought us $16K in additional monthly income. Throughout our years of partnership, we have witnessed firsthand how VentorTech’s analysts extract maximum value from automation. They continue to be a trusted partner in our journey toward continued success.”

About the company

The client is a number one seller of specialized products in the US. They stand out by offering high-quality items that undergo rigorous quality control checks. In addition, the client provides same-day shipping, ensuring fast and convenient delivery to customers. With their extensive inventory and top-notch service, the client has established itself as the go-to destination for specialized spare parts in the region.

Problems

The client operates its company using Odoo ERP and has a standard inventory workflow in their warehouse: receiving items in the input zone, moving them to the warehouse, and subsequently picking them for shipment to customers.

However, unusual business and specific products provide some hidden challenges.

Suppliers don’t provide the list of items, and it’s critically important to identify every product as fast as possible move them to the warehouse, making them available for sale in their online shop.

So, the problems were as follows:

- Incorrect inventory information

Often, items would get stuck in the virtual input location. Although they were physically moved to the warehouse and in Odoo Inventory, they remained in the input zone. As a result, these items were not reflected as ‘available for sale.’

- Long period to be available for sale (up to a month)

The problem above resulted in inability to sell products until a complete inventory adjustment in Odoo was completed. Sometimes items could be stored in the warehouse for a month before they became available in the online shop.

- Difficulty in finding lost items quickly

The client lacked a mechanism to efficiently find items that were either not properly recorded in the system or mistakenly moved. For instance, situations occurred when there was an internet connection loss, when warehouse workers forgot to validate transfers in Odoo, or when they had validated them in incorrect locations.

- Lack of foolproof measures for warehouse workers

In the event of any trouble or complications, dishonest workers had the potential to neglect item movement registration in Odoo, leaving the items unaccounted for. Impossibility to prevent these occurrences posed challenges in maintaining an organized warehouse.

Goals

The client conveyed their goal to design and implement, in Odoo, a workflow that would achieve the following:

- Ensure that supplied products are available for sale within one hour after they have left the input zone.

- Implement a transparent and manageable process of filling in the warehouse with products.

- Establish measures to prevent goods from being lost within the warehouse.

Worried about your Odoo Inventory efficiency?

Solution

Analysis

Our analyst conducted a comprehensive data collection process, gathering inventory records, sales data, and feedback from warehouse workers. This data served as the foundation for quantifying the extent of the problem, identifying patterns, and understanding the underlying causes.

To visualize the existing reception process, a detailed process mapping exercise was performed. This involved documenting each step, from product reception to stock location movement, and then pinpointing key touchpoints where issues were prevalent.

“This data served as the foundation for quantifying the extent of the problem, identifying patterns, and understanding the underlying causes.”

Aleksey Panko, BA at VentorTech

Our analysts explored various potential solutions, including process improvements and the feasibility of implementing barcode scanners connected to Odoo via Ventor, a leading warehouse management app for Odoo. Each solution was evaluated for its benefits, drawbacks, and potential impact on the overall process.

Based on the analysis, a Proof of Concept (POC) was developed. This involved creating a limited and simplified version of the proposed solution to assess its effectiveness and determine if it introduced an acceptable additional time to the reception process.

The POC underwent evaluation through simulations, which were preformed to assess its impact on the reception process, accuracy of inventory management, and ease of resolving discrepancies. The results of the evaluation formed the basis for a recommendation regarding the implementation of the suggested solution, along with proposed customizations and improvements.

To further strengthen the proposed solution, our team calculated the financial losses incurred from each product lost and determined the average quantity of lost products per month.

The POC, accompanied by a guarantee of return on investment, was presented to the customer, and the solution was implemented.

Useful link: Why the discovery phase is so important

Designed workflow

What is a Bin?

– In this project, a “bin” is implied to be a big metal container that holds about 40 items. The customer has about 20 such bins and moves them via a warehouse loader.

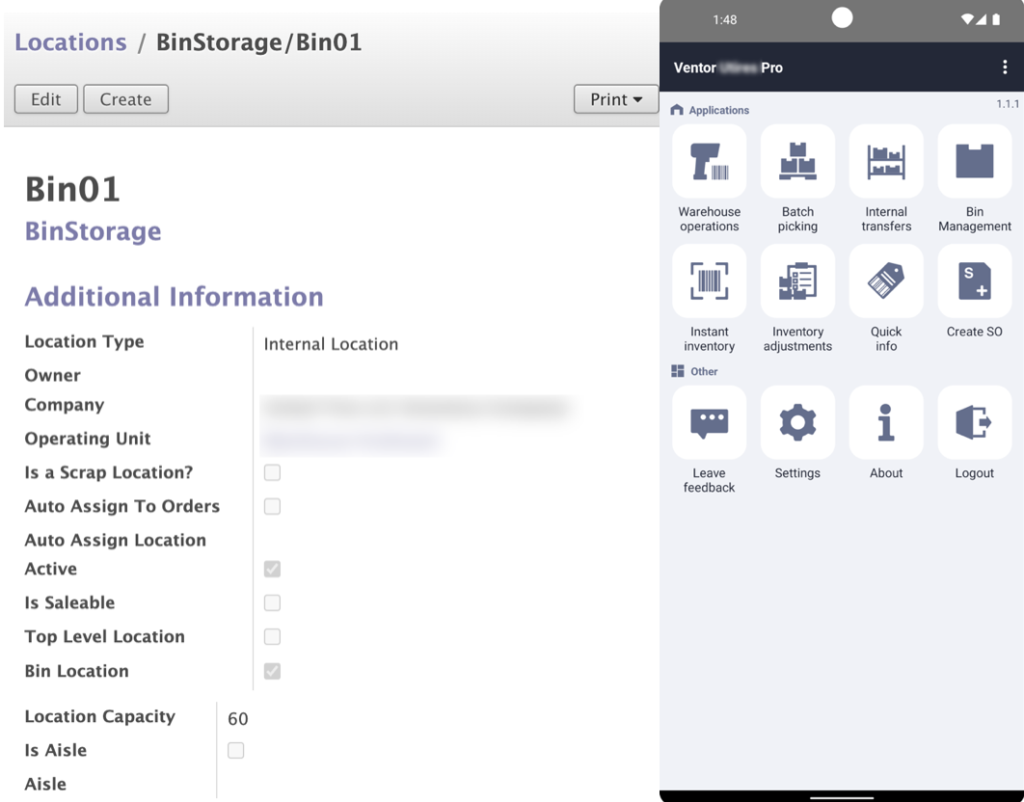

New Bin Location and Bin Management menu:

A new bin location type with a limited capacity was added in Odoo. The additional menu ”Bin Management” was implemented and added to the Ventor mobile app.

The workflow is as follows:

- Workers fill a bin with any items they find in the input zone. When the bin is full, a worker scans items using a handheld computer with Ventor installed and presses “Move to the bin”. Ventor validates the transfer from input to the bin.

- Warehouse workers move bins within the warehouse on loaders. When the worker finds free space, they press “Move item from the bin”, scan the item and a warehouse location, and validate this internal transfer from the bin to a saleable location. From this point, the item is available for sale in the online shop.

- Workers move through the warehouse until they empty the bin.

If, at the end, the worker realizes that the bin is empty but Ventor shows that there is still an item(s) in the bin, or vice versa, the bin contains an item(s) but Ventor shows an empty bin, it means that discrepancies arose.

In this case, the manager can see recent transfers (Odoo stock moves) from any particular bin location in a dedicated tab. They can check which users were working with the bin location and in what warehouse zone to address possible issues.

Experience the power of Ventor PRO, the leading warehouse management app for Odoo.

Cost and lead time of the implementation

Team

- 0.5 BA/PM

- 0.25 Android developer

- 0.25 QA

Note: This implementation did not require an Odoo developer. It primarily involved functional configuration and customization within an Android app (mobile development).

Lead time

1 month

Cost

~$10K + Ventor PRO subscription

Results

Additional monthly income of $16K

Now all products are quickly available for sale after leaving the input zone. We analyzed the number of lost items before the implementation and compared this to the extra income after the implementation. The numbers showed an additional monthly income of $16K or nearly $200K annually. This result more than justifies the investment made.

Accurate inventory information

All movements from the input zone to the warehouse are now correctly registered in Odoo, ensuring precise and up-to-date location information for all stored items. This improvement yielded three key benefits:

- Within internal transfers, workers can now confidently ensure that the destination location is free and ready to receive products. Previously, there was a risk of moving items to locations that may have contained lost or misplaced items.

- During the picking process, pickers can easily locate the items in the guided locations, minimizing interruptions and delays. Previously, pickers often had to pause their tasks to search for lost items or correct orders.

- Monthly Inventory Adjustment is no longer necessary, as lost goods are found on the go during the movement from input to the warehouse.

These improvements in inventory accuracy and efficiency have allowed for the optimization of warehouse staff or the reallocation of workers to other departments (such as, for example, the service station).

“Generally speaking, the bin functionality works great without any significant obstacles. We’re still working on the best way to manage the bins and the personnel, but we did reduce the amount of goods that are stuck in input significantly.”

Still unsure about investing in automation for your business? Define the ROI you can expect from implementing automation solutions tailored to your needs

Read other success stories: