Company Name: SMContact

Country: France, China, Germany, Spain, Estonia

Industry: Electronics

Company size: 50-100 employees

VentorTech solutions: Odoo consulting and implementation

Goal: Routine automation in sales, purchase, logistics, and accounting operations

“We owe thanks to VentorTech for their excellent support throughout our digital transformation with Odoo”

Evgeniy Belosludtsev, Head of Digital Transformation at SM Contact

This story was presented at Odoo Experience 2023, featuring Evgeniy Belosludtsev, Head of Digital Transformation at SM Contact, and Oleg Kuryan, CEO of VentorTech.

You can watch a video interview here:

About The Company

SM Contact is an international leader in a specialized niche within the electronics industry, focusing on connectors, connections, qualifications, and equipment. They have offices in six countries, with headquarters in France and annual turnover exceeding 7 million euros.

Why Odoo

Here and below the narration will be from the Client’s point of view:

We began implementing Odoo in 2018, choosing it over SAP and other systems because it is online, customizable, and provides source code access even for the enterprise version, enhancing our security. Additionally, the Odoo market offers a variety of modules for different needs, and there is a global pool of software developers available should any adjustments be required.

I will now discuss some of the best Odoo implementation case studies from various departments, including sales, logistics, manufacturing, bookkeeping, and purchasing.

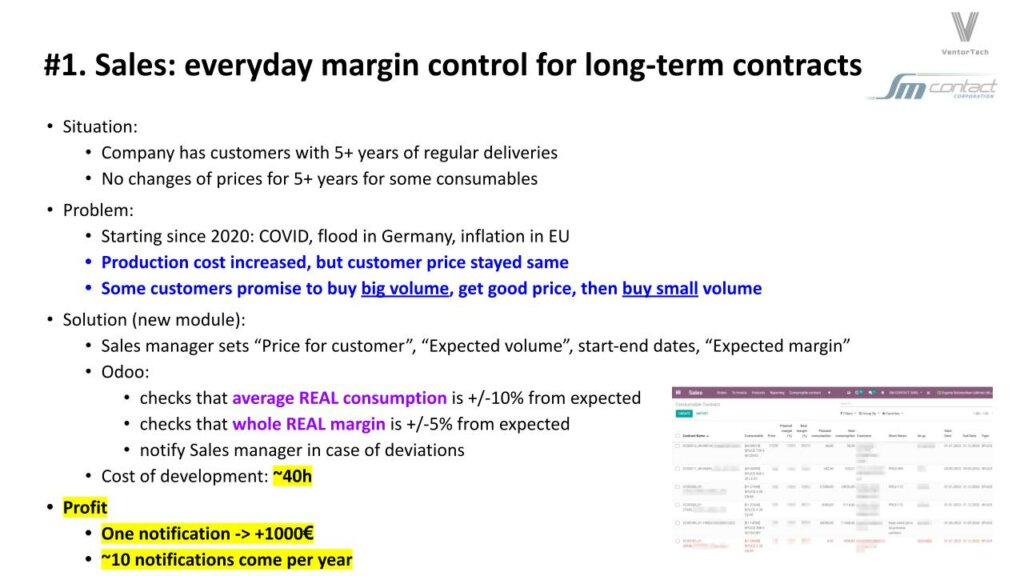

Sales margin control in Odoo

Problem

Previously, our ERP system could not track signed contracts. Five years ago, due to almost zero inflation in the European Union, contract prices were never reconsidered. However, following events such as COVID, floods, or metal shortages, the cost of raw materials increased. Despite this, we did not adjust the prices of our contracts. Another issue was that some customers, promising high volumes to secure better prices, would end up purchasing minimal amounts, which went undetected.

Solution

The Odoo script, developed by VentorTech, compares real and expected consumption and margins in real-time every day for consumable contracts by identifying deviations greater than approximately 10% for consumption or 5% for margins. It automatically sends a notification to the responsible person, such as the Head of Sales, potentially saving us up to €1,000.

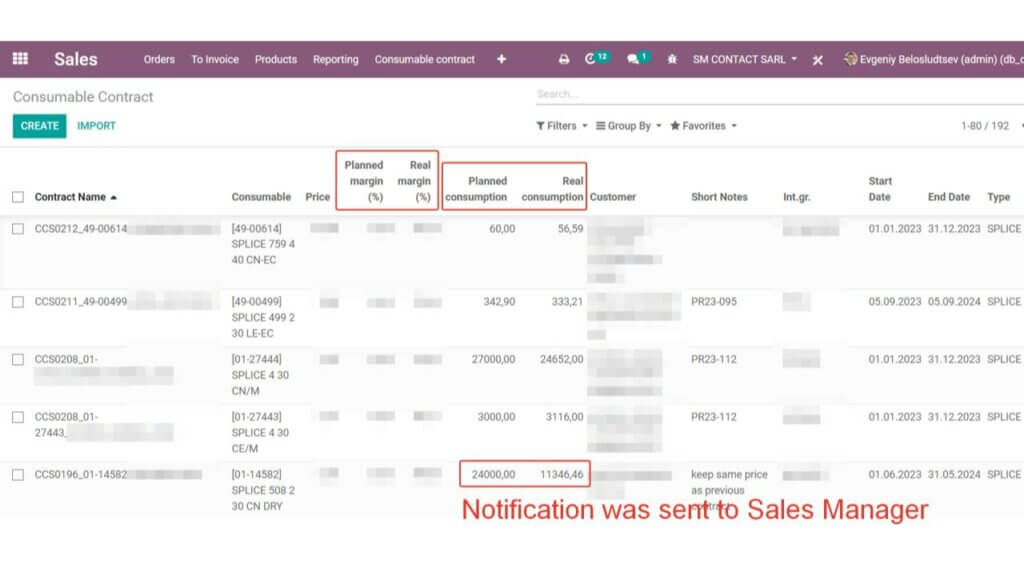

Example:

In our system, I have highlighted new columns in red for planned and actual margins, as well as planned and actual consumption. If actual consumption falls below expected levels, a notification is automatically sent to the sales manager. These checks are performed bi-monthly to ensure continuous monitoring.

Profit

We receive about 10 notifications per year and earn €10,000 just from effective contract tracking. The development costs were significantly lower, totaling approximately 40 hours for this specific script.

You might be interested: How an Odoo Inventory optimization generated $200K for a US company

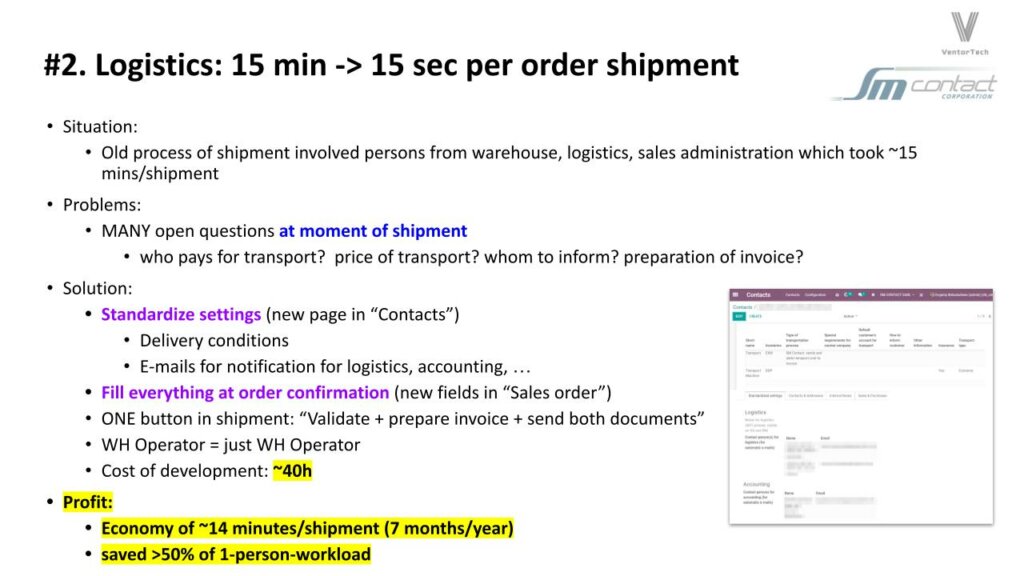

Logistics automation with Odoo

We are particularly proud of this adjustment, which dramatically reduced shipment processing time from 15 minutes to just 15 seconds—a 60-fold improvement.

Problem

We are particularly proud of this adjustment, which dramatically reduced shipment processing time from 15 minutes to just 15 seconds—a 60-fold improvement. This challenge is familiar in many industries. Often, when orders are packed and ready to ship, there are questions about who should pay for shipping and manage the process—should it be the manufacturer or the customer? Is it better to use the customer’s shipping account with companies like TNT or DHL, or handle it ourselves and bill the customer later? Deciding who gets the delivery note is another common issue.

Solution

To make the process smoother, we standardized how we set up shipping and delivery conditions. We clarified terms like XWorks, who is responsible for transportation costs, whether products are shipped or picked up, and how we communicate with customers (phone, email, or through a customer portal). Our goal was to make sure that all these details were clearly laid out when an order was confirmed.

After confirmation, the warehouse operator’s job is simple: hit the “Validate Delivery Note” button and send out the invoices using the templates in Odoo. This lets him focus on getting things done efficiently instead of getting bogged down in logistics details.

Example:

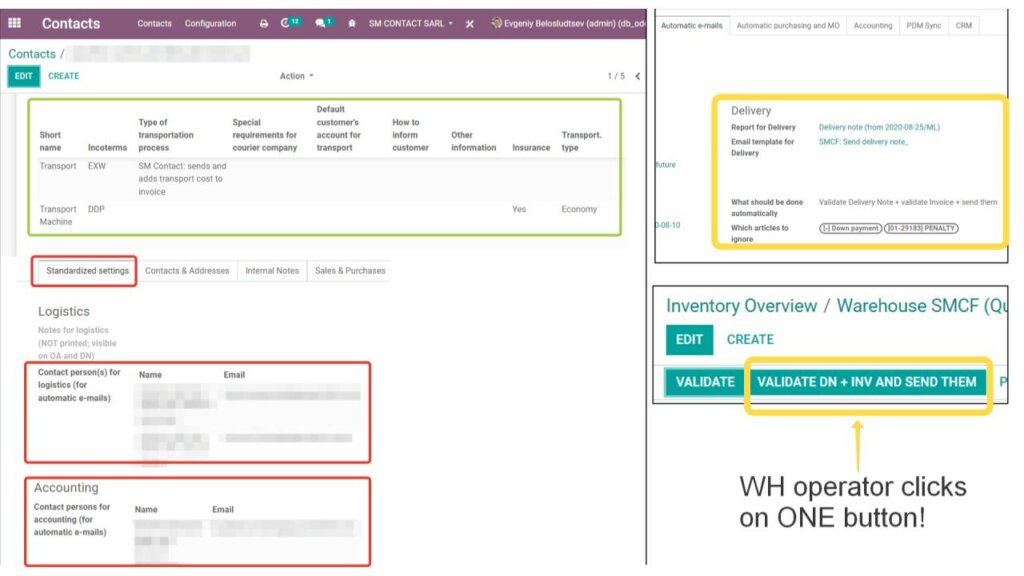

Displayed in green are the standardized delivery conditions, including XWorks, responsible parties for transportation, transport type, and insurance details. In red, you see standardized settings for how delivery notes and invoices should be communicated. In yellow are the settings for automated deliveries; for example, we have configured specific report templates for delivery confirmations. The “Validate DN note and INV and send them” button is operational only when all settings are correctly configured. If settings are incomplete, the operator is prompted to consult their manager for resolution, ensuring all criteria are met before proceeding.

Shipping Standardization in Odoo

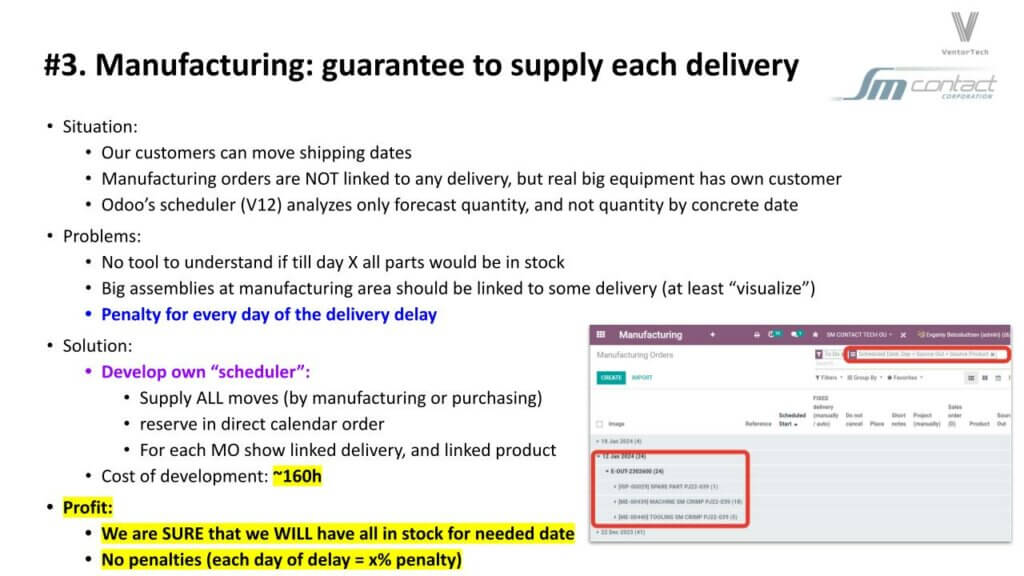

Delivery schedules control in Odoo Manufacturing

This sub-project represents our most advanced and extensive development effort to date, executed in several phases, with highly successful outcomes.

Problem

In Odoo version 12, there is no built-in connection between manufacturing orders and delivery schedules. This setup works fine for small components that fit into various equipment types. However, for larger projects, like machinery that involves 7-8 stages of material buildup and includes over 1,500 parts costing upwards of 100,000 euros, it’s crucial to connect manufacturing orders directly to the specific machines making these parts. This connection is vital because any delay in delivery can lead to financial penalties for the manufacturer.

With only the basic automation features, it was difficult to ensure that all necessary components were available when needed. For instance, if a product needed to be shipped on December 1st and assembly was to begin on November 1st, there was no certainty that all parts would be ready by the start date. The standard Odoo scheduling tool could only predict part availability based on existing stocks and update manufacturing orders as parts were bought.

Solution

The Odoo algorithm developed by VentorTech enhances this process by checking whether inventory levels are adequate or exceed the average after all manufacturing steps are completed. This check is crucial to ensure that we have all necessary parts ready by the time production is scheduled to start. If any issues with manufacturing or delivery arise, Odoo automatically creates a new manufacturing or purchase order to fill any gaps, ensuring that we always have enough parts in stock.

If discrepancies or issues are detected, the manufacturing or purchase manager investigates the cause and fixes it.

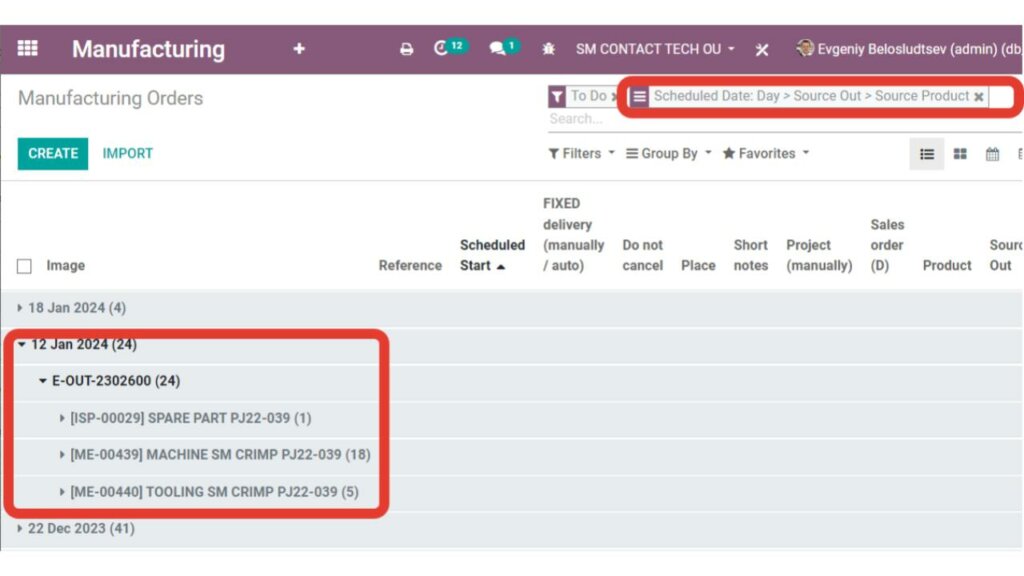

The attached screenshot shows how manufacturing orders are organized by date and linked by source output to each delivery. This system enables detailed tracking of specific items within a delivery, showing that a delivery can contain multiple similar parts or assemblies.

Profit

Developing this Odoo customization took 160 hours, but the investment has been extremely worthwhile. We now have confidence that our inventory levels will satisfy our manufacturing needs, helping us avoid fines. Given the high costs of our equipment—ranging from one hundred to two hundred thousand euros—a delay of even 1% or a tenth of a percent in delivery can justify the expense of this development.

Delegate your most important processes under Odoo’s control

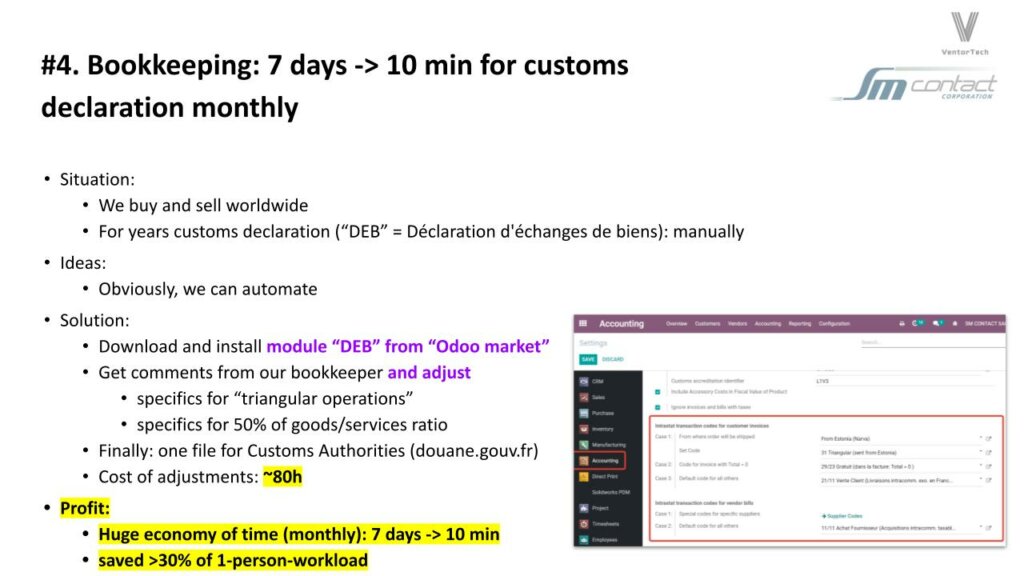

Automation of customs declaration with Odoo

We transformed the bookkeeping process from requiring seven days to just ten minutes per month.

Problem

Before, handling customs declarations required significant effort because it involved manually collecting information about the country of origin and other details from multiple sources.

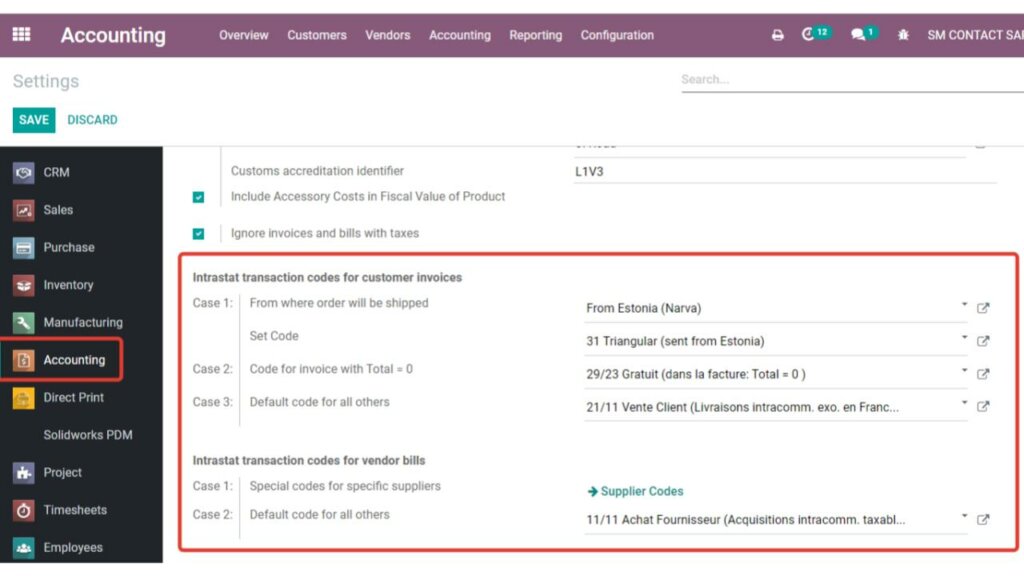

Solution

VentorTech suggested leveraging an existing module from the Odoo marketplace, known as DEB or DB and DS. Initial feedback from our bookkeepers indicated that the module did not fully meet our needs, prompting us to make further adjustments.

Profit

After approximately 80 hours of customization, we achieved a time saving of about seven days per month. Annually, this equates to over 80 days, roughly four months of work, offering a significant reduction in labor costs or an opportunity to reallocate resources.

By automating tasks, such as the preparation of customs declarations, we reduced the workload of our bookkeepers by 30%.

You might be interested: Odoo QuickBooks Online integration

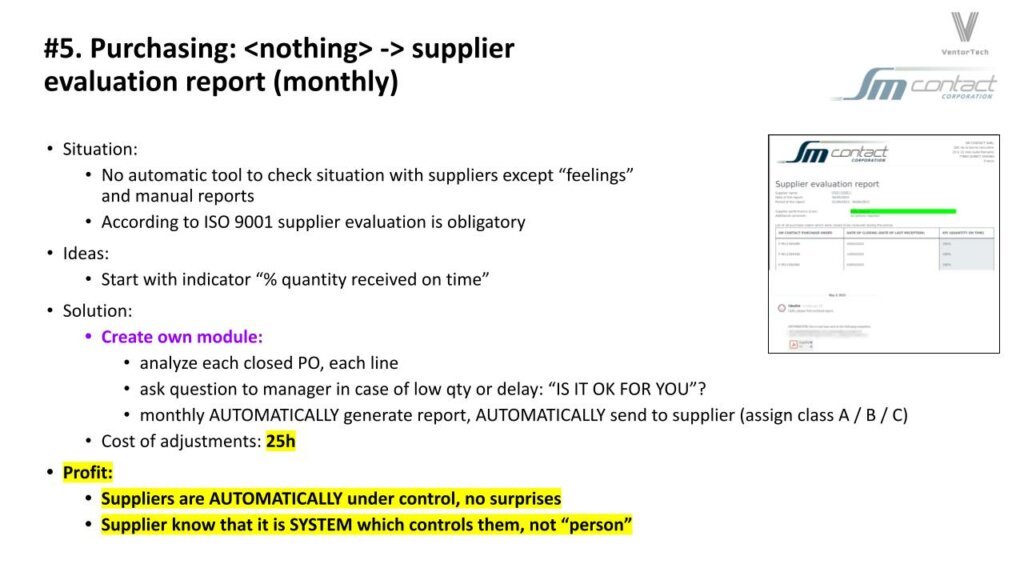

Supplier evaluation in Odoo

Problem

Previously, there was no effective system in place for tracking supplies, despite requirements set by ISO standard 90001.

Solution

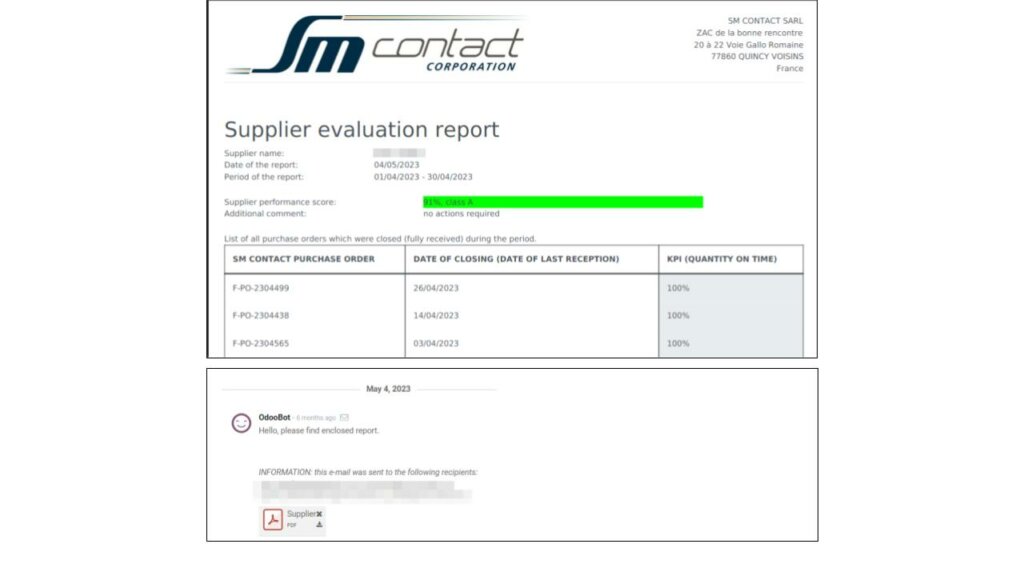

VentorTech developed a custom module to analyze each purchase order upon closure. If a purchase order is not closed on time, the purchase manager is tasked with ensuring that any delays or discrepancies in quantity are within acceptable limits. Each month, this process triggers an automatic report that is sent to the supplier.

Example:

In our supply report, we track the report date, and the period it covers, by classifying it under class ABC based on performance metrics. This system closes each purchase order on the noted date and aligns with predefined KPIs. The log note even includes an automatic report sent on specific dates, such as the 4th of May, to maintain rigorous standards.

Profit

This system ensures suppliers are consistently monitored, reducing surprises and human errors.

Suppliers know that they must stay in A level to get more orders from us.

You might be interested: Create purchase orders using only a barcode scanner

Tips and Tricks of Odoo Implementation

It’s important to understand that Odoo and its available modules might not be a perfect fit right off the bat. We initially learned this through some tough experiences, but thankfully, making adjustments isn’t usually too costly. Odoo is highly adaptable—much like building with Lego. It allows for real-time changes using actual data, which significantly boosts productivity. Plus, the cost of developing these adjustments is often just a small part of the savings they bring over a year, making them a smart financial decision. We are grateful to VentorTech for their outstanding support during this process.

We are strong proponents of using a Return on Investment (ROI) approach before starting any projects. This method involves calculating both the effort needed and the potential financial benefits, and it has proven to be the best way to ensure projects are successful. This strategy has been crucial to achieve our objectives and maintain high efficiency in our operations.

Conclusion

The key to our success in digital transformation has been the steadfast support from our CEO, who is committed to continuous improvement. This support is vital for fully utilizing Odoo’s capabilities in all aspects of our business. Equally important is having the right team, with each member in a role that suits their strengths, which is essential for our continued progress.

Delegate your most important processes under Odoo’s control

Recommended articles:

- From Manual to Automated: How Odoo ERP Helped a Swiss IT Service Company to Grow Turnover 2.5 Times

- Odoo and Ventor solution for 27 Finnish stores: from manual inventory management to fully automated WMS

- Top 10 Reasons to Choose Odoo ERP for Your Business

- Create purchase orders using only a barcode scanner