Company Name: United Tires

Country: United States, IL

Industry: Automotive

Company size: 51-200 employees

VentorTech solutions: Ventor (Odoo Barcode app), Direct Print App, Ecommerce connectors, Odoo consulting and implementation

Goal: Full business automation (sales, purchase, logistics, warehouse, etc.) using ROI based approach

“Thank you VentorTech for all the hard work throughout the years, it’s been quite a journey. Definitely would recommend for warehouse optimization and business process automation. Very reputable and great team to work with!”

Volodymyr Barabakh, CEO of United Tires

This story was presented at Odoo Experience 2024, featuring Volodymyr Barabakh, CEO of United Tires and Vitaly Eremeev, the CBDO at VentorTech.

You can watch a video interview here:

Then vs Now

First of all, let’s discuss the company United Tires, or “Utires”, as some call it. This company is currently number one in the United States for selling used tires online, but that wasn’t always the case. Let’s quickly look at how things were going for them before they started working with Odoo.

You can see some ‘before’ pictures here that we’ve requested from the client. On the left side, you can see one of the co-founders of the company, sitting on a batch of used tires that they had just unloaded from a truck. He’s trying to figure out how to fit all of these tires into their very small warehouse at the time, which was only about 150 square meters. It was a super-small space with basic shelving and wooden panels. If you look at the quality of the picture, you can see that it was taken many years ago with a phone camera, so it’s a bit blurry. Even this shows how much things have changed over the past 10 years.

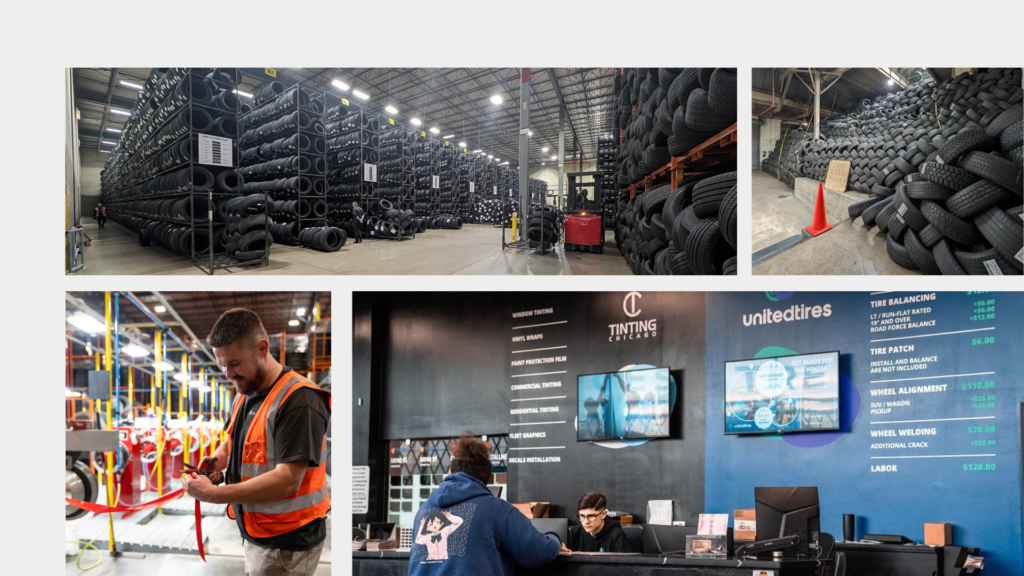

Now, if you look at where they are today, you’ll see one of their five warehouses—this is probably the biggest one. You can see different zones for incoming shipments, reception, picking zones, and so on. They have come a long way, growing together with us, with Odoo technology, and more.

In addition to selling used tires, they now offer various car maintenance services, such as oil changes, filter changes, tire repairs, glass replacements, car tuning, sound system upgrades, and more. But now we’re getting into where they are today. Instead, let’s discuss the challenges they faced around 10 years ago when they first came to us.

Сhallenges

At the time, they were using multiple tools, which is common for many companies when they first start off—things like Trello, spreadsheets, Airtable, and other different software solutions. Nothing was organized, and they didn’t have dedicated vendor or department structures. Many of you as business owners know what it’s like to do many things by yourself, and that was the case here too. They did not have a dedicated IT department, nor a warehouse management system (WMS), or an inventory management solution.

Order picking and sorting took too long, and they couldn’t grow efficiently without a WMS implementation. Also, as a unique business, selling used tires comes with unique challenges—like checking the quality and condition of each item before sending it to customers, ensuring guarantees, quality levels, and so on. They lacked finance management software as well. So, the client was doing the best they could, but they were limited by their lack of a proper system.

The new system needed to be flexible and scalable enough to support growth from 20 employees to hundreds without limits. Spoiler alert: This is where Odoo and our VTech team helped them to integrate a scalable solution.

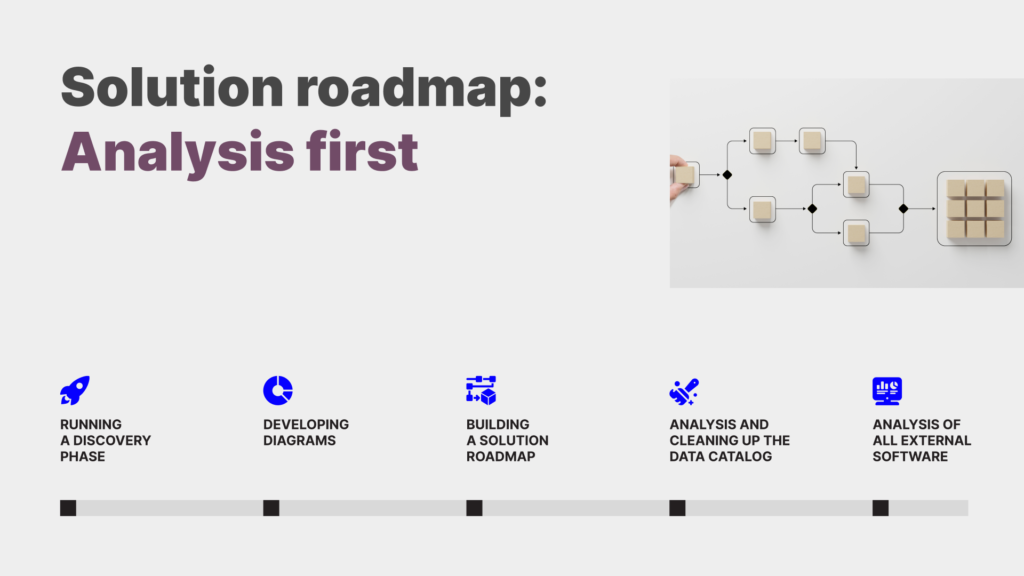

Solution roadmap: Analysis first

We began with a discovery phase, collected all their requirements and pain points, and then created process diagrams to map out and improve their business workflows. We prioritized tasks and created a solution roadmap to address their goals in phases. We spent much time cleaning up the data catalog, because, with used tires, it’s common to have multiple similar items, like 20 different Michelin tires in various sizes, treads, and conditions. Some tires were damaged; others were not. Managing these distinctions was essential, so we developed a strategy to address these needs.

Inventory management was a huge bottleneck because they were losing money due to delayed orders and couldn’t afford to hire more people to manage it. We helped them map their warehouse layout, plan optimal routes, and optimize inventory topology, including naming aisles, and zones, and setting distances between shelves. We also conducted order analyses, such as ABC and XYZ analyses, to identify their best-selling items and prioritize them.

To enhance efficiency, we suggested using handheld devices with vendor-specific software for faster item picking. We built an optimized route on the warehouse map, enabling them to print and attach shipping labels directly on the spot while picking each tire. This saved about three hours per day in sorting time alone.

Need an optimized route for your warehouse?

One major challenge in the used tire business is that you never know exactly what’s in each incoming shipment. Every container holds thousands of tires, but each has to be inspected for quality, then cleaned, checked for damage, repaired if needed, and moved to the shelves. We built a custom wizard for the company to process incoming containers faster, allowing them to manage up to 5,000 tires per day per warehouse.

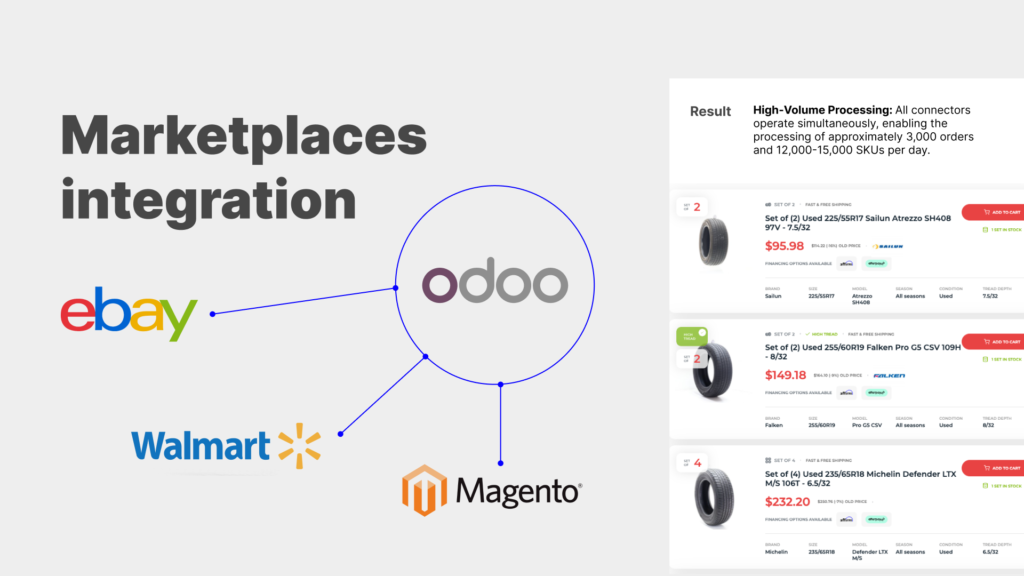

Marketplaces integration

We also integrated their marketplace channels—eBay, Walmart, Magento, and their web shop—since Odoo’s website solution wasn’t capable of handling such a large volume of orders at that time. These robust integrations have lasted eight years, scaling as they increased orders by tenfold, which shows their strength.

We developed an interactive warehouse map, viewable on large TV screens placed between aisles. This allows workers to see available storage spots in real time, thus saving time and improving the efficiency of put-away and picking tasks. Small but crucial features like bin management allow them to quickly rearrange items as needed.

Omnichannel management was another area we tackled, integrating notifications on platforms like WhatsApp and Telegram for real-time updates. We perform constant performance monitoring to identify bottlenecks and continuously improve the system as they expand.

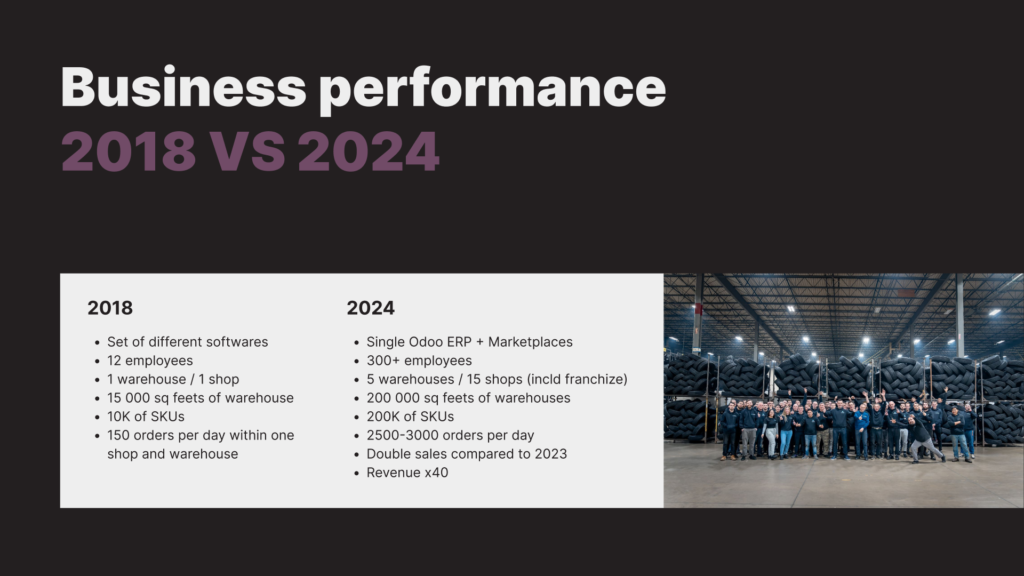

Business Performance 2018 vs 2024

Over time, scaling has become easy. When the client wants to open a new warehouse, we can replicate the process seamlessly. Let’s compare their business performance over the years that we have been with them: 6 years ago, they had a patchwork of software, one warehouse, 12 employees, and a single shop. Now, with Odoo and our integrations, they have grown to 300 employees across 5 warehouses and 15 shops, with unlimited franchise locations throughout the U.S.

Their facilities have expanded from 15,000 to 200,000 square feet, with SKUs increasing from 10,000 to 200,000, and daily orders rising from 200 to 3,000. Last year’s sales doubled, and revenue has multiplied by 40 over the years. This success demonstrates that Odoo can indeed support a small business as it grows into a large-scale enterprise.

Testimonial

Although our client in the United States couldn’t join us today, they recorded a message for us.

Q&A

Q1: How did you initially engage with this client, and how did they find you?

About 10 years ago, they noticed we were starting to build expertise in inventory management and logistics, and we had just released a handheld solution. At that time, Odoo had no barcode interface or similar tool, so we were actually the first company to develop a logistic solution on this platform. They saw Odoo’s potential and recognized that they needed handheld devices for their operations. We onboarded them with Odoo and our handheld solution, and our collaboration grew from there.

Q2: Is the discovery phase valuable in the beginning, and what was the process for such a complicated client?

The discovery phase is crucial for a project like this. We need to analyze the real gaps between the client’s needs and what the system can achieve. This phase allows us to understand their goals, identify priorities, and propose the simplest path forward. We aim to avoid unnecessary customizations, which saves the client time and money while ensuring we meet their core needs.

Q3: Did you focus solely on Odoo ERP implementation, or were you also involved in improving and optimizing warehouse processes?

We work primarily on Odoo implementations but collaborate with local logistics experts worldwide when needed. We provide basic warehouse setup and management but also bring in specialized partners for large-scale projects. Our network allows us to integrate best practices and receive feedback to continuously improve our solutions.

Q4: How long did this implementation project take, and what was the team size involved from the client side?

At the start, we had two analysts and a developer working with about ten people on the client’s side. We went live within a year, which was fast for a project of this scale. Over time, we’ve added features and supported new marketplaces, maintaining a steady relationship for over eight years. Today, they’ve grown to be the top used tire seller online in the United States.

Q5: Are you planning to develop products in other fields?

Our focus is on logistics, printing, handheld devices, inventory management optimization, and sales automation. Our priority is quality over quantity, so we concentrate on these core areas. You can find our products in the official Odoo App Store, accessible for companies globally to improve their processes.

Q6: Is warehouse visualization directly in the Ventor app, or is it a dedicated module?

It’s a dedicated module displayed on large screens within the warehouse. This allows workers to quickly see what’s available without needing in-depth system knowledge, making work easier for seasonal employees as well.

Q7: How do you manage to do this internally?

We focus on building long-term relationships with clients, which allows us to grow together. Loyalty to Odoo keeps clients coming back to us as they expand. Our team started small but has grown to about 80 people equipped with technical skills, hardware, software integration, and in-depth knowledge of inventory and supply chain management. This allows us to support larger clients over the years.

Interested in growing your business with Odoo?

Recommended articles:

- From Manual to Automated: How Odoo ERP Helped a Swiss IT Service Company to Grow Turnover 2.5 Times

- Odoo and Ventor solution for 27 Finnish stores: from manual inventory management to fully automated WMS

- How Odoo implementation automated 10 months of manual work and saved over €22K annually

- Odoo Success Story: From Budget Overruns to a Profitable Tech Company in Just 6 Months

- 10 most common questions to the official Odoo partner

- Top 10 Reasons to Choose Odoo ERP for Your Business